Heating Blankets for Welding: Essential Tools for Temperature Control

Welding heating blankets help control temperature during and after welding. They prevent cracks, reduce stress, and ensure proper cooling. This guide explains their types, uses, and benefits for professional welders.

What Are Heating Blankets for Welding?

Heating blankets for welding are flexible thermal covers that maintain or control temperature in welded joints. You wrap them around pipes, tanks, or structural components before, during, or after welding. These specialized blankets come in various sizes and temperature ranges to suit different welding applications.

Why Use Heating Blankets in Welding?

When you weld thick materials or high-carbon steels, uneven cooling causes problems. Heating blankets solve this by:

- Preventing rapid cooling that leads to cracks

- Reducing residual stress in the weld zone

- Maintaining preheat temperatures for difficult metals

- Ensuring proper post-weld heat treatment (PWHT)

Types of Welding Heating Blankets

1. Silicone Rubber Heating Blankets

These flexible blankets withstand temperatures up to 450°F (232°C). You'll find them ideal for most carbon steel welding applications. Their silicone construction resists oils and chemicals common in industrial environments.

2. Ceramic Fiber Blankets

For higher temperatures (up to 1800°F/982°C), ceramic fiber blankets work best. They're perfect for stainless steel or alloy welding where you need extended heat retention.

3. Custom-Shaped Blankets

Some projects require specially shaped heating blankets that conform to pipes, elbows, or complex geometries. Manufacturers can create custom blankets for your specific welding needs.

How to Choose the Right Heating Blanket

Selecting proper heating blankets for welding depends on three factors:

- Material thickness:Thicker materials need higher temperature blankets

- Metal type:Different alloys require specific temperature ranges

- Project size:Measure your workpieces to get adequate coverage

Proper Use of Welding Heating Blankets

To get maximum benefit from your heating blanket:

- Clean the surface before application

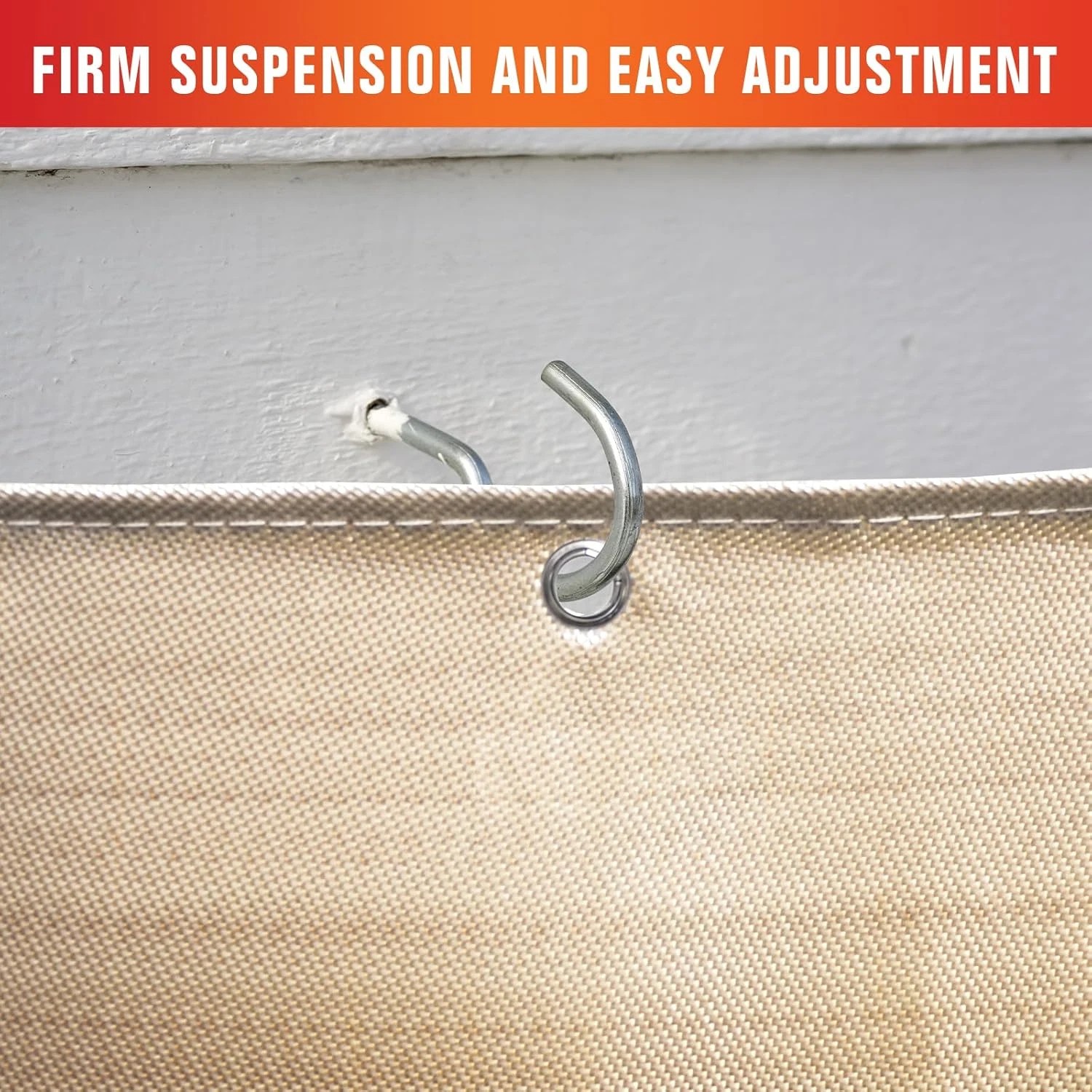

- Secure the blanket tightly with straps or fasteners

- Monitor temperatures with thermocouples

- Follow the manufacturer's heating/cooling rate recommendations

Safety Precautions

While heating blankets for welding improve results, remember these safety tips:

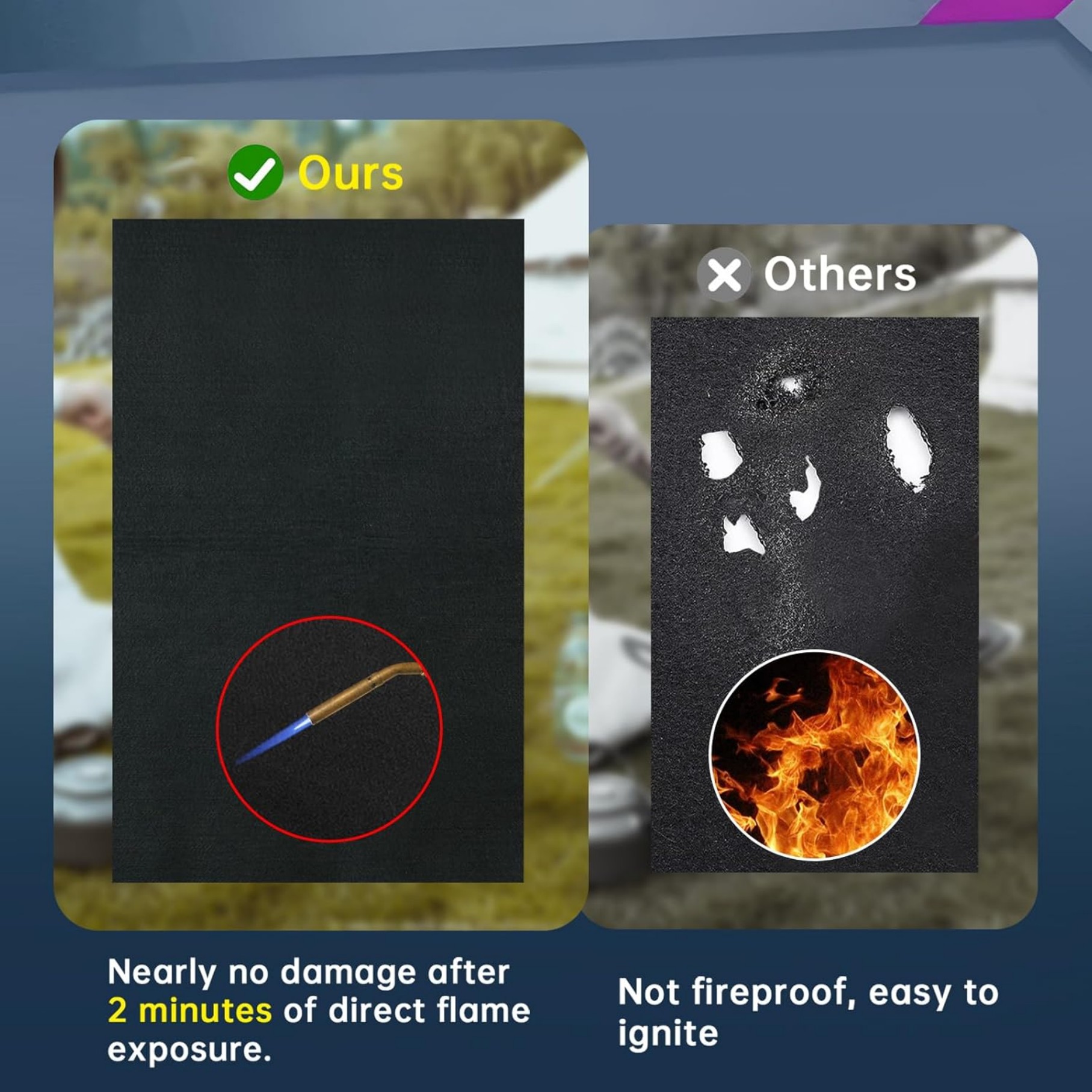

- Never exceed the blanket's maximum temperature rating

- Inspect for damage before each use

- Keep flammable materials away

- Use proper insulation between the blanket and surroundings

Maintenance and Storage

Proper care extends your heating blanket's life:

- Cool completely before folding

- Store in dry conditions away from sharp objects

- Clean with compressed air or soft brushes

- Check electrical components regularly (for electric models)

Common Applications

Professional welders use heating blankets in these situations:

- Pipeline welding and repairs

- Pressure vessel fabrication

- Shipbuilding and offshore structures

- Power plant maintenance

- Aerospace component welding

Cost vs. Benefits Analysis

While heating blankets for welding represent an investment, they save money by:

- Reducing rework from failed welds

- Extending equipment lifespan through proper heat treatment

- Meeting code requirements for critical welds

- Saving energy compared to oven treatments

Conclusion

Heating blankets for welding are essential tools that improve weld quality and efficiency. By understanding their types, proper use, and benefits, you can select the right solution for your welding projects. Always prioritize safety and follow manufacturer guidelines for best results.