Graphite Welding Blanket Guide: Uses, Benefits and Safety Tips

Summary:Graphite welding blankets protect surfaces from sparks and heat during welding. They're flexible, durable, and withstand extreme temperatures. This guide explains their benefits, proper usage, and safety considerations for optimal protection.

What Is a Graphite Welding Blanket?

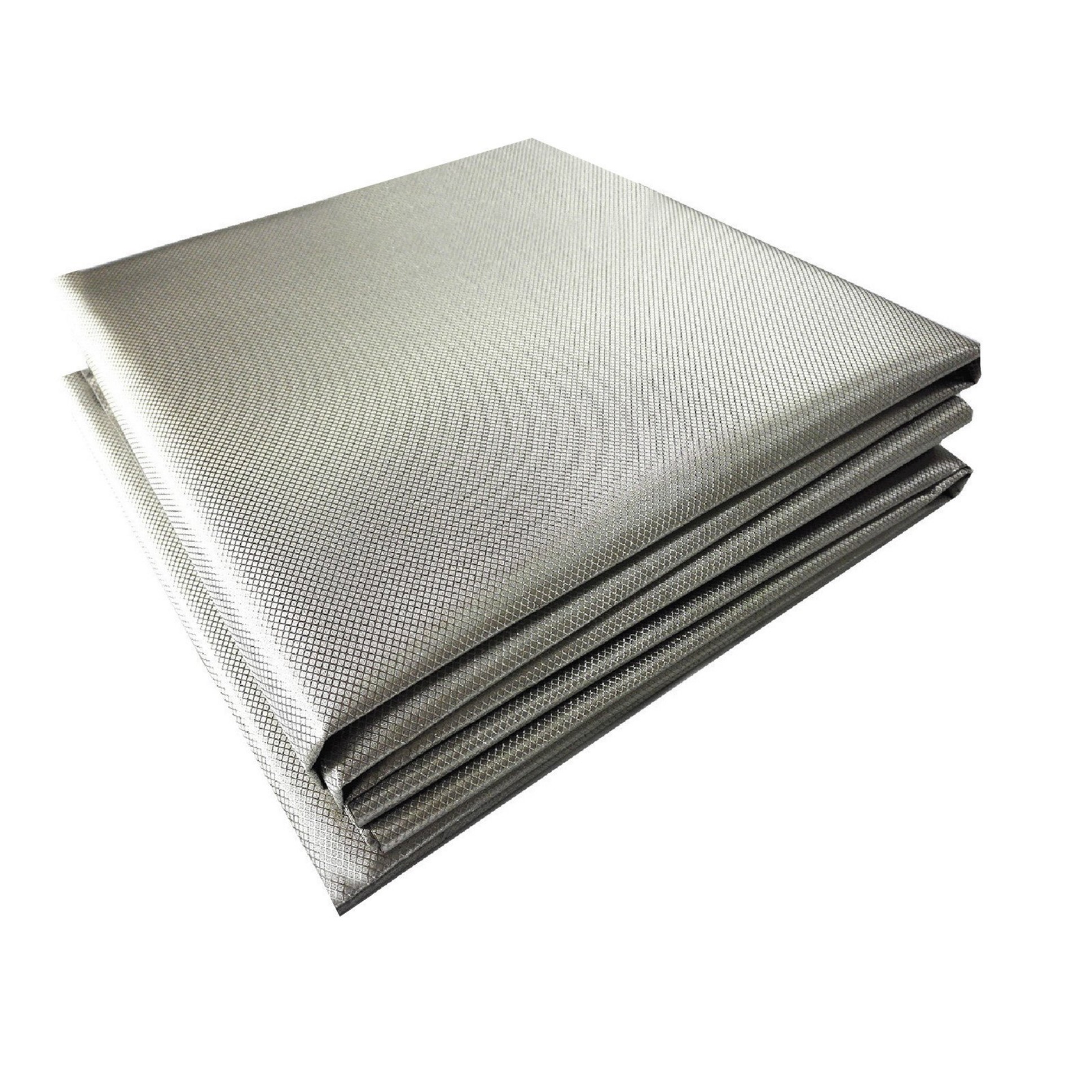

When you're welding, sparks and molten metal can damage nearby surfaces. A graphite welding blanket solves this problem. It's a heat-resistant protective layer made from graphite-coated fiberglass fabric. Unlike regular welding blankets, graphite versions offer superior heat reflection and durability.

Key Benefits of Using Graphite Welding Blankets

You'll appreciate these advantages when using graphite welding blankets:

- Extreme heat resistance:Withstands temperatures up to 2000°F (1093°C)

- Spark protection:Prevents fire hazards from welding sparks

- Reusable:Lasts longer than disposable alternatives

- Flexible:Conforms to uneven surfaces easily

- Chemical resistant:Handles most industrial chemicals

How to Choose the Right Graphite Welding Blanket

Selecting the proper graphite welding blanket depends on your specific needs:

Size matters:Measure your work area. Common sizes range from 4'x4' to 10'x10'. Larger blankets protect more area but cost more.

Thickness considerations:Thicker blankets (1/8" to 1/4") offer better protection for heavy-duty welding but are less flexible.

Temperature rating:Match the blanket's rating to your welding process. MIG welding typically requires lower ratings than plasma cutting.

Proper Usage and Maintenance Tips

To get the most from your graphite welding blanket:

- Always inspect for damage before use

- Secure edges with weights or clamps to prevent movement

- Overlap multiple blankets by at least 6 inches when covering large areas

- Clean with compressed air or a soft brush - never use water

- Store flat or rolled - never fold to prevent crease damage

Safety Considerations

While graphite welding blankets enhance safety, remember these precautions:

Never use a damaged blanket - small tears can compromise protection. Keep flammable materials at least 3 feet away from welding areas, even when using blankets. Always wear proper PPE (personal protective equipment) - the blanket protects surfaces, not you.

Graphite vs. Other Welding Blanket Materials

How does graphite compare to alternatives?

| Material | Max Temperature | Pros | Cons |

|---|---|---|---|

| Graphite | 2000°F | Best heat reflection, most durable | Higher cost |

| Fiberglass | 1000°F | Affordable | Less durable |

| Silica | 1800°F | Good flexibility | Heavier |

Common Applications

Graphite welding blankets protect in various scenarios:

- Automotive repair shops

- Shipbuilding and marine welding

- Pipeline construction

- Industrial maintenance

- Artistic metalworking studios

Conclusion

A graphite welding blanket is a smart investment for any serious welder. It provides reliable protection for your work area, lasts through countless projects, and ultimately saves you money by preventing damage. Choose the right size and thickness for your needs, maintain it properly, and always prioritize safety for the best results.