High-Temp Protection: How Silicone Welding Blankets Improve Workplace Safety

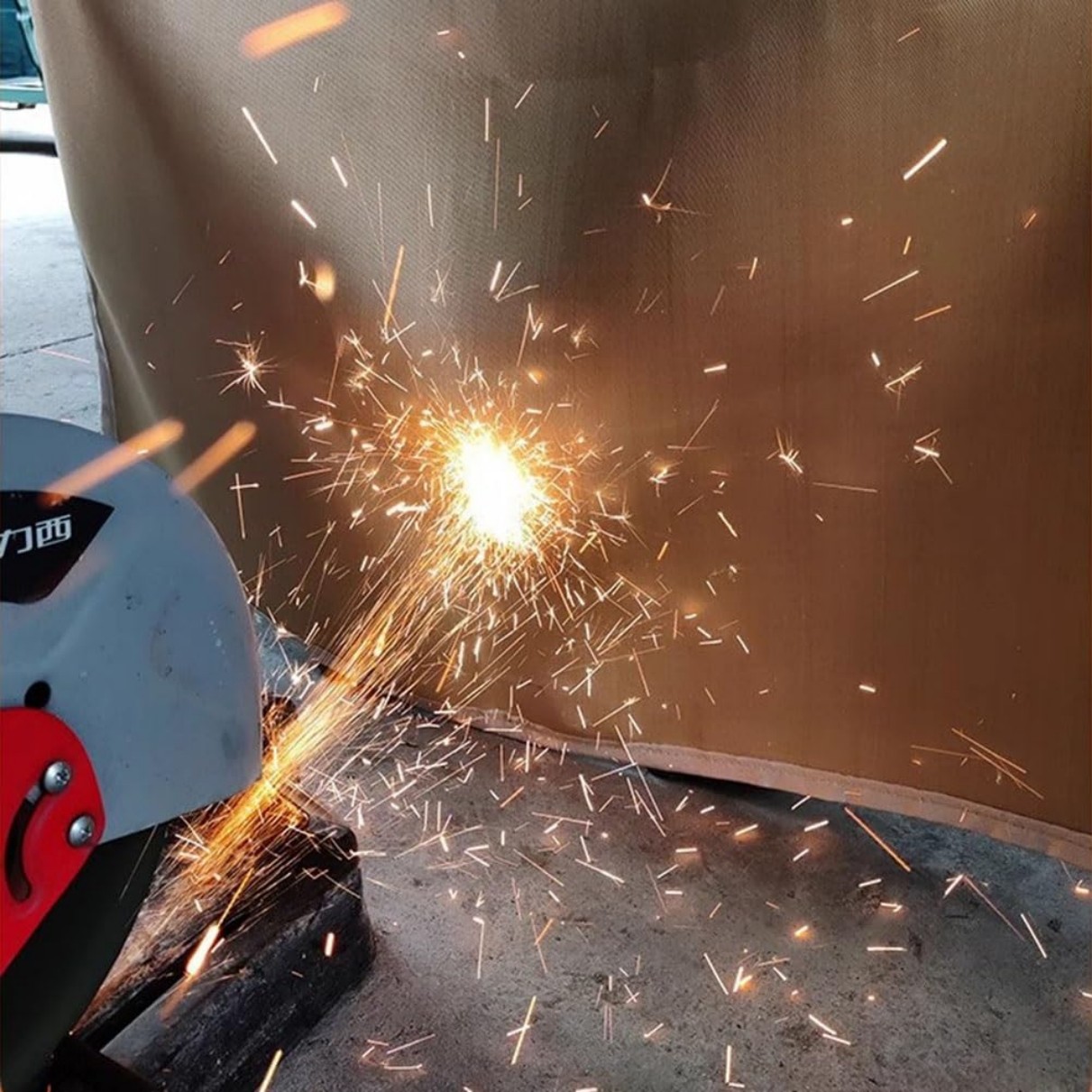

Silicone welding blankets provide essential heat and spark protection during welding operations. These durable, flexible barriers shield workers and equipment from extreme temperatures up to 2000°F while resisting flames and molten metal splatter.

What Makes Silicone Welding Blankets Special?

Unlike ordinary welding blankets, silicone-coated versions offer superior performance. The silicone surface creates a non-stick barrier that prevents molten metal from adhering. This makes cleanup easier and extends the blanket's lifespan significantly.

The core material typically consists of fiberglass fabric, which provides excellent thermal insulation. When coated with high-grade silicone, this combination creates a lightweight yet incredibly durable protective solution.

Key Benefits for Your Workspace

- Extreme heat resistance:Withstands temperatures from -100°F to +2000°F (-73°C to +1093°C)

- Flame retardant:Won't catch fire or support combustion

- Molten metal protection:Silicone coating prevents welding spatter from sticking

- Flexible and lightweight:Easy to drape over equipment or use as curtains

- Reusable:Lasts much longer than disposable alternatives

Choosing the Right Silicone Welding Blanket

When selecting a silicone welding blanket, consider these factors:

Thickness:Thicker blankets (1/8" to 1/4") offer better protection for heavy-duty welding but are less flexible. Thinner options work well for light applications.

Size:Measure your work area. Common sizes range from 3'x3' for small jobs to 10'x10' for large workstations.

Color:While most are silver-gray, some manufacturers offer color-coded options for different temperature ratings.

Reinforcement:Look for grommets or reinforced edges if you need to hang the blanket securely.

Proper Use and Maintenance

To get the most from your silicone welding blanket:

- Inspect regularly for tears or excessive wear

- Clean with compressed air or a soft brush - avoid harsh chemicals

- Store flat or rolled - avoid folding which can create weak points

- Replace when the silicone coating shows significant wear or the fabric becomes brittle

Always position the blanket so sparks and molten metal fall away from workers. For maximum protection, use multiple layers in high-risk areas.

Applications Beyond Welding

While designed for welding, these versatile blankets serve many purposes:

- Foundry work and metal casting

- Fireproofing in laboratories

- Protecting floors during grinding operations

- Insulating pipes and boilers

- Emergency fire blankets

Safety Standards and Certifications

Quality silicone welding blankets meet several important standards:

- OSHA 1910.252 for welding safety

- NFPA 701 for flame resistance

- ASTM F1959 for arc flash protection

Always verify that products carry appropriate certifications for your industry and application.

Cost vs. Value Analysis

While silicone welding blankets cost more upfront than basic fiberglass versions, their durability makes them more economical long-term. A quality blanket can last 5-10 times longer than uncoated alternatives with proper care.

Consider the hidden costs of workplace injuries or equipment damage when evaluating protection options. The investment in proper safety gear like silicone welding blankets pays dividends through reduced downtime and liability.

Where to Buy Quality Silicone Welding Blankets

Purchase from reputable industrial safety suppliers who provide:

- Detailed product specifications

- Manufacturer warranties

- Technical support

- Custom sizing options

Many suppliers offer samples so you can evaluate material quality before larger purchases.

By understanding these key aspects of silicone welding blankets, you can make informed decisions to enhance safety and efficiency in your welding operations. The right protection solution saves money, prevents injuries, and helps maintain productivity in demanding industrial environments.