Welding Blanket for Floor Forum: Ultimate Protection Guide

Summary:This guide explains how welding blankets protect floors during projects, key features to look for, and why floor forums recommend them. Learn proper usage, safety tips, and top product recommendations.

Why You Need a Welding Blanket for Floor Protection

When working on welding projects, your floor faces serious risks from sparks, slag, and heat. A welding blanket for floor protection acts as a fire-resistant barrier. Many floor forums highlight how these blankets prevent costly damage to concrete, wood, or tile surfaces. Unlike regular drop cloths, welding blankets withstand temperatures up to 1,800°F.

Key Features to Look For

According to floor protection experts on welding forums, quality blankets should have:

- Fiberglass or silica fabric construction

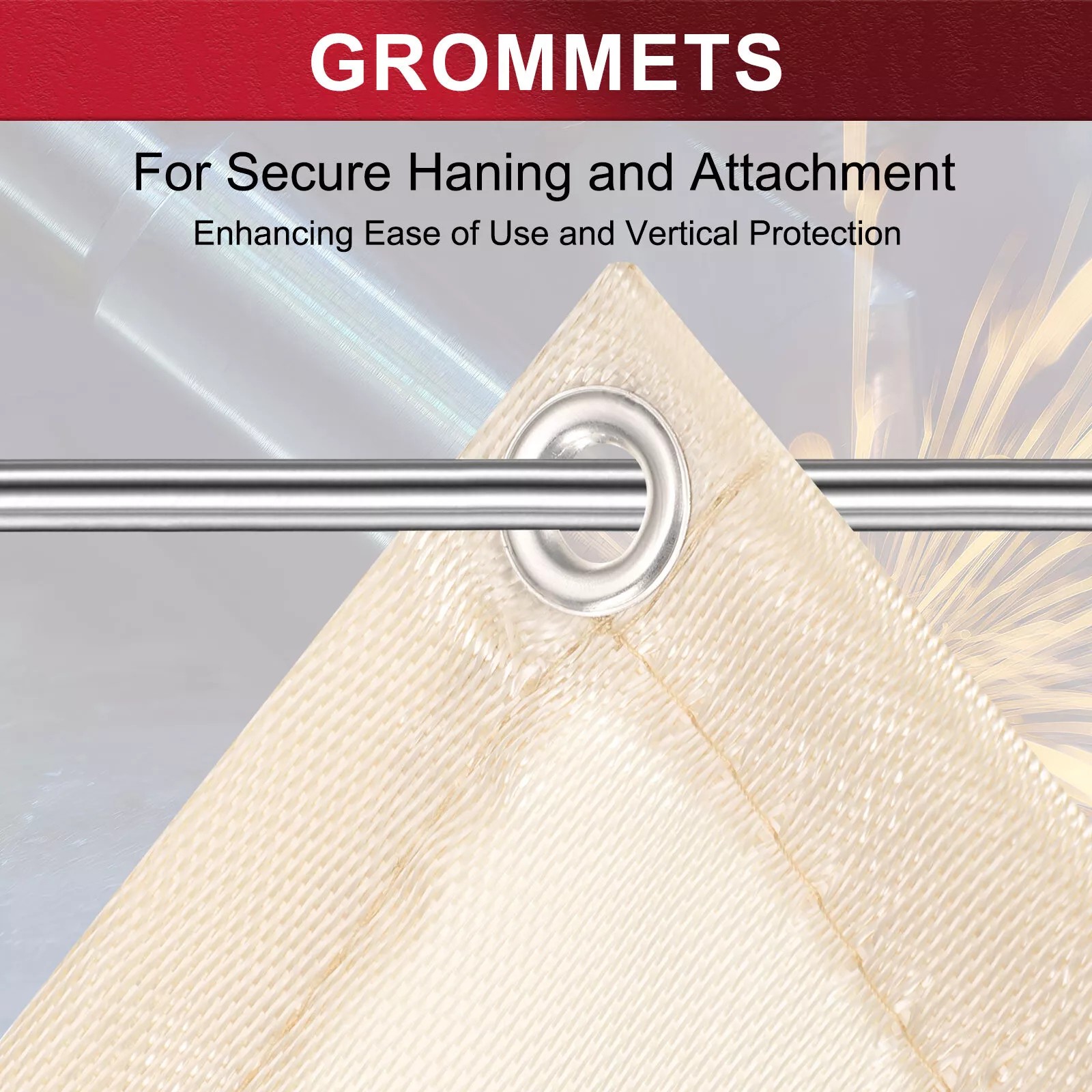

- Reinforced edges with grommets for secure placement

- Proper size coverage for your work area

- Temperature rating matching your welding type

- Flexibility for easy storage

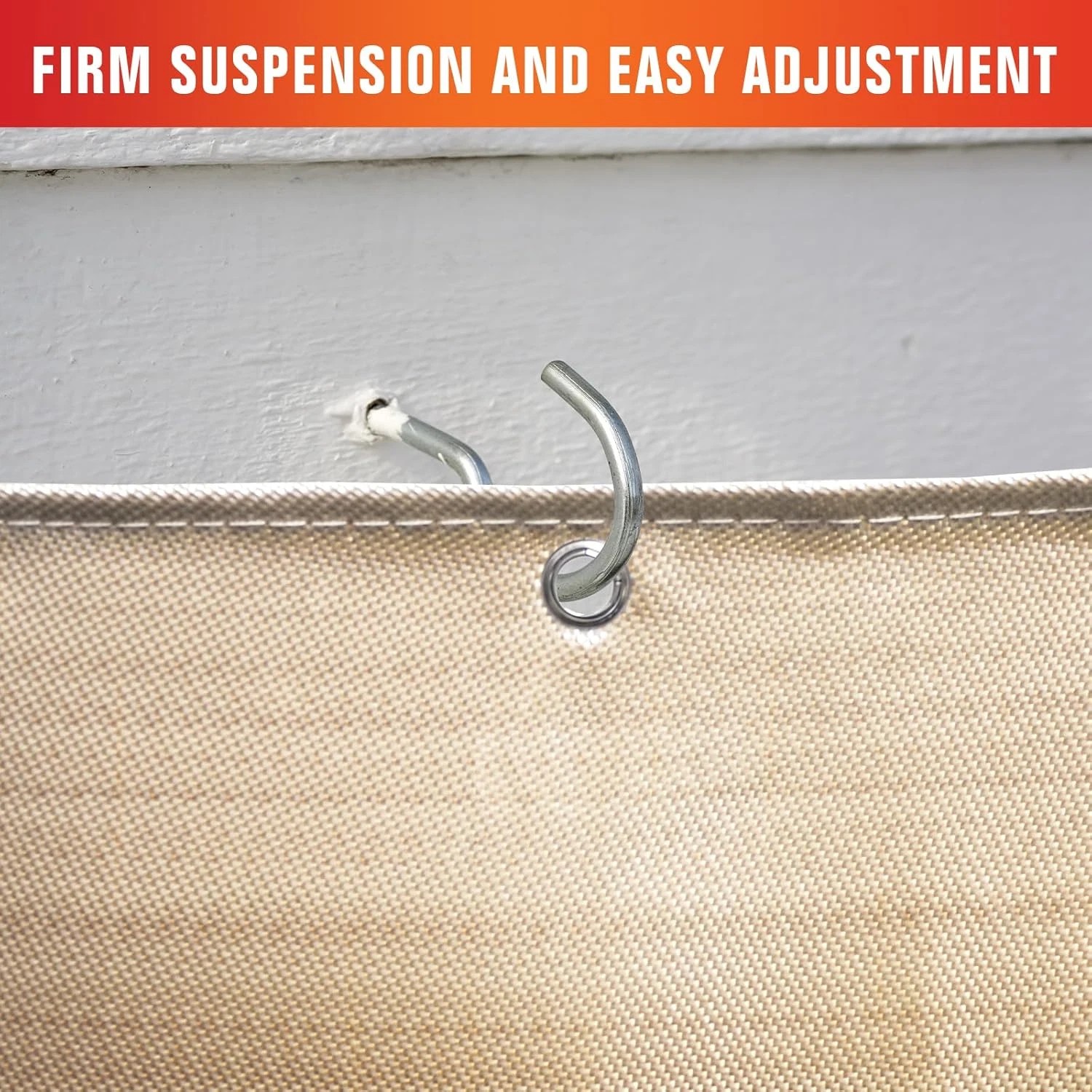

Proper Installation Techniques

Floor forum discussions emphasize correct blanket placement:

- Clean the floor surface first

- Overlap multiple blankets by at least 6 inches

- Secure edges with weights or clamps

- Extend coverage at least 3 feet beyond work area

- Inspect for tears before each use

Common Mistakes to Avoid

Welding blanket threads on floor forums frequently mention these errors:

- Using damaged blankets with holes

- Placing blankets over wet surfaces

- Choosing undersized coverage

- Ignoring manufacturer's temperature limits

- Storing while still hot

Top-Rated Products Recommended by Floor Forums

After analyzing hundreds of forum posts, these welding blankets receive consistent praise:

| Product | Size | Temp Rating | Forum Rating |

|---|---|---|---|

| Black Stallion FB-4X6 | 4' x 6' | 1,800°F | 4.8/5 |

| Lincoln Electric K2989 | 6' x 8' | 2,000°F | 4.9/5 |

| TEKON 3-Layer Blanket | 8' x 8' | 2,500°F | 4.7/5 |

Maintenance and Care Tips

Floor forum veterans recommend:

- Shake out debris after each use

- Hand wash with mild detergent when needed

- Inspect for fiberglass exposure

- Store flat or rolled (never folded)

- Replace when fibers become brittle

Alternative Floor Protection Methods

While welding blankets dominate floor forum discussions, some alternatives exist:

- Ceramic fiber boards (for stationary work)

- Fire-resistant floor paints

- Metal drip pans (for small projects)

- Custom welding curtains with floor skirts

However, most forum members agree welding blankets offer the best combination of protection, portability, and cost-effectiveness.

Conclusion

Whether you're a professional welder or DIY enthusiast, a quality welding blanket for floor protection proves invaluable. As countless floor forum posts demonstrate, proper selection and use prevents damage, improves safety, and saves money long-term. Always prioritize certified products and follow manufacturer guidelines for optimal results.