Fire Blanket for Valves: Protection & Safety Solutions for Industrial Systems

Summary:Fire blankets for valves are specialized safety devices that protect critical valve systems from fire damage. They prevent heat transfer, contain leaks, and maintain valve functionality during emergencies, crucial for industrial safety.

What Is a Fire Blanket for Valves?

When you work with industrial valve systems, fire protection is non-negotiable. A fire blanket for valves is a flame-resistant cover designed specifically to shield valves from extreme heat and flames. Unlike general-purpose fire blankets, these are engineered to fit valve shapes while allowing operational access.

You'll find them made from advanced materials like fiberglass with silicone coatings or ceramic fibers. These materials can withstand temperatures up to 2000°F (1093°C) while remaining flexible enough to wrap around complex valve configurations.

Why Your Facility Needs Valve Fire Blankets

Valves control critical flows in pipelines - whether chemicals, fuels, or gases. During a fire, unprotected valves can fail catastrophically:

- Metal components warp under heat, causing leaks

- Seals and gaskets melt, losing containment

- Actuators malfunction when overheated

A properly installed fire blanket for valves gives you three key benefits:

- Thermal insulation:Slows heat transfer to protect internal components

- Flame barrier:Prevents direct flame contact with valve surfaces

- Operational integrity:Maintains valve functionality during emergencies

Choosing the Right Fire Blanket for Your Valves

Not all fire blankets work equally well for valves. Consider these factors when selecting yours:

Material Composition

High-performance options include:

- Ceramic fiber blankets:Best for extreme temperatures (1800-2000°F)

- Silicone-coated fiberglass:Good chemical resistance (1200-1500°F)

- Vermiculite-based:Excellent for hydrocarbon fires

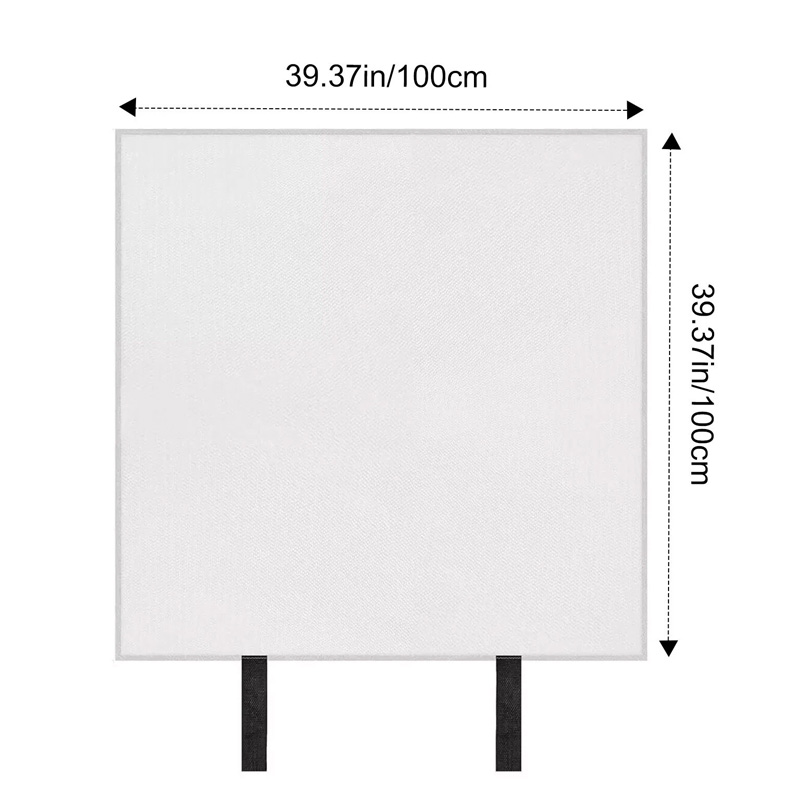

Design Features

Look for these practical elements:

- Pre-cut openings for valve stems and handles

- Adjustable straps or fasteners for secure fitting

- Reflective outer layers to repel radiant heat

- Chemical-resistant coatings if handling corrosive substances

Proper Installation of Valve Fire Blankets

Even the best fire blanket for valves won't perform if installed incorrectly. Follow these steps:

- Clean valve surfaces to ensure proper adhesion

- Position the blanket to cover all critical components

- Secure all fasteners without over-tightening

- Leave necessary clearances for valve operation

- Inspect monthly for damage or displacement

Remember: Fire blankets for valves work best when combined with other fire protection measures like sprinklers and detection systems.

Maintenance and Inspection Guidelines

To ensure your fire blanket for valves remains effective:

- Conduct visual inspections quarterly

- Check for tears, discoloration, or hardening

- Test fasteners and straps annually

- Replace every 5-7 years or after any fire exposure

- Keep installation records for compliance audits

Industry Applications

Fire blankets for valves prove essential in:

- Oil & Gas:Wellheads, pipeline valves, refinery systems

- Chemical Plants:Reactor feed lines, transfer valves

- Power Generation:Steam system valves, fuel controls

- Marine:Engine room valves, fuel transfer systems

Cost vs. Risk Analysis

While fire blankets for valves represent an investment, consider:

- A single valve failure during fire can cost millions in damage

- Regulatory fines for inadequate protection often exceed blanket costs

- Insurance premiums may decrease with proper fire mitigation

- Blankets typically cost $200-$800 per valve depending on size and material

Conclusion

A fire blanket for valves isn't just another safety item - it's critical protection for your most vulnerable system components. By selecting the right materials, installing properly, and maintaining diligently, you ensure valves remain operational when you need them most. In industrial settings where fire risks exist, these specialized blankets provide cost-effective, reliable defense against catastrophic valve failures.