Fiberglass Welding Blanket: Fire Retardant Protection for Safe Welding Operations

Summary:Fiberglass welding blankets provide essential fire retardant protection during welding. These heat-resistant barriers prevent sparks and molten metal from causing fires, making them crucial for workplace safety. Learn how they work and why you need them.

What is a Fiberglass Welding Blanket?

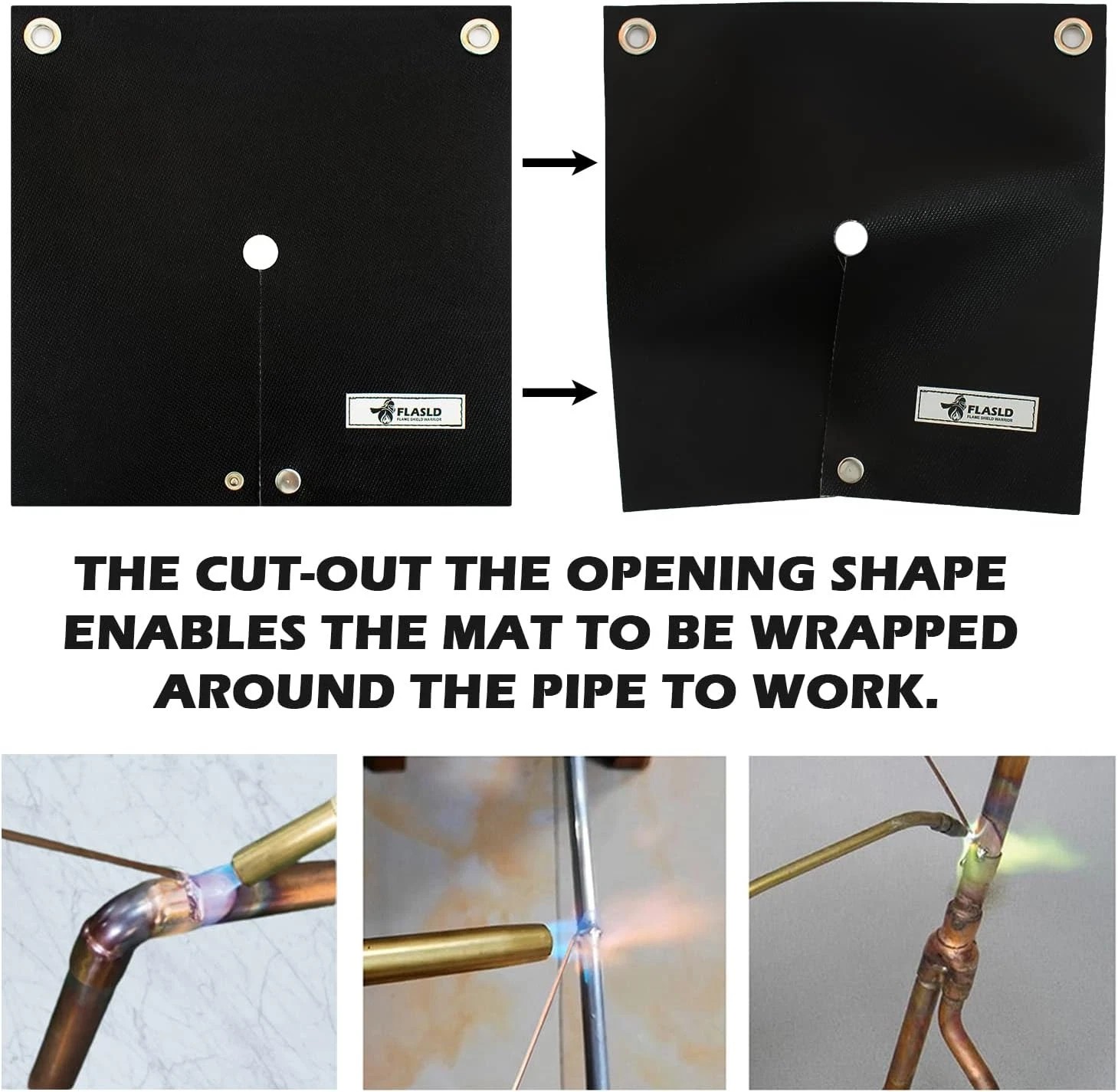

When you're welding, sparks and molten metal can fly several feet, creating serious fire hazards. A fiberglass welding blanket is your first line of defense. Made from woven fiberglass fabric with fire retardant treatment, these blankets withstand temperatures up to 1,800°F (982°C). They're flexible yet durable enough to protect surrounding areas from welding hazards.

How Fire Retardant Fiberglass Blankets Work

The secret lies in the material composition. Fiberglass naturally resists heat, but the special fire retardant treatment adds extra protection. When sparks hit the blanket, they're immediately smothered rather than igniting. The tight weave prevents molten metal from penetrating through to surfaces underneath. You get three layers of protection: heat resistance, flame suppression, and spark containment.

Key Benefits for Your Workspace

Using a fiberglass welding blanket with fire retardant properties gives you multiple advantages:

- Prevents workplace fires:Contains sparks and slag that could ignite flammable materials

- Protects surfaces:Keeps workbenches, floors, and equipment safe from heat damage

- Reusable protection:Unlike disposable alternatives, these blankets last through multiple jobs

- Versatile applications:Useful for welding, grinding, foundry work, and fireproofing

- Compliance with safety standards:Meets OSHA and other regulatory requirements

Choosing the Right Blanket for Your Needs

Not all fiberglass welding blankets offer equal protection. Consider these factors when selecting yours:

- Temperature rating:Match the blanket's maximum temperature to your welding processes

- Thickness:Thicker blankets (typically 1/8" to 1/4") provide better protection

- Size:Ensure coverage for your work area plus extra margin

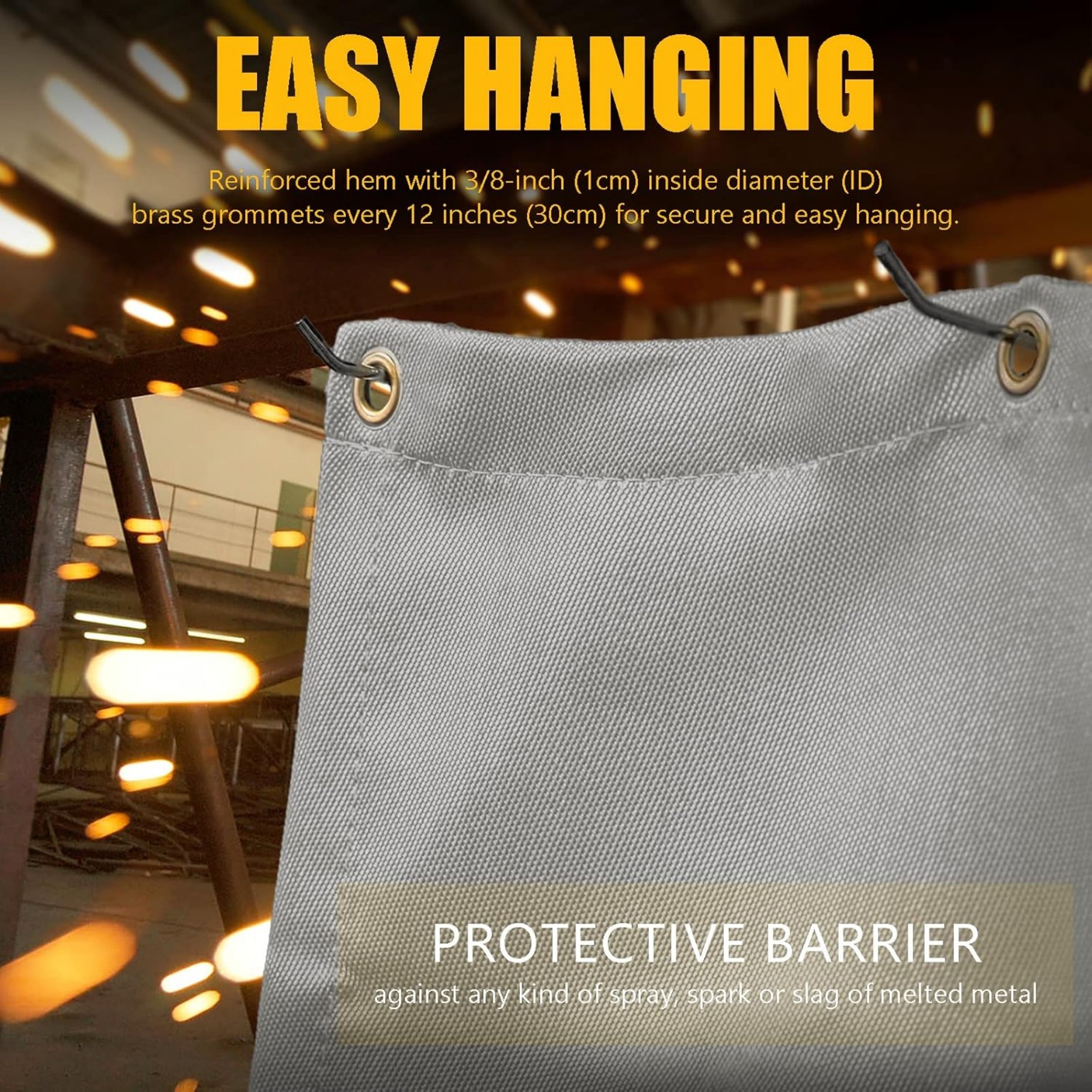

- Edge treatment:Look for reinforced edges that resist fraying

- Certifications:Verify compliance with relevant safety standards

Proper Use and Maintenance

To get the most from your fire retardant fiberglass welding blanket:

- Always position the blanket to fully cover vulnerable areas

- Keep it at least 18 inches away from the actual welding point

- Inspect regularly for tears or excessive wear

- Clean with compressed air or a soft brush - never use water

- Store flat or rolled, never folded, to prevent crease damage

Beyond Welding: Additional Applications

While designed for welding, these fire retardant blankets serve multiple purposes:

- Protecting surfaces during metal grinding operations

- Containing sparks during torch cutting

- Emergency fire blankets for small workshop fires

- Insulation for high-temperature equipment

- Foundry work involving molten metal handling

Safety First: Why You Should Never Skip This Protection

A quality fiberglass welding blanket with fire retardant properties isn't optional equipment - it's essential safety gear. The small investment prevents costly property damage, potential injuries, and work stoppages from fire incidents. Remember that no welding job is too small to warrant proper protection. Make your fiberglass welding blanket part of your standard safety protocol for every welding task.