Fiberglass Welding Blankets: Heat Protection for Safe Metalwork

Summary:Fiberglass welding blankets protect against sparks, slag, and heat up to 2000°F. They're essential for welding safety, preventing fires, and shielding nearby surfaces. Learn their benefits, proper use, and key features for optimal protection.

What Are Fiberglass Welding Blankets?

Fiberglass welding blankets are heat-resistant safety tools made from woven fiberglass fabric. When you weld, cut, or grind metal, these blankets protect your workspace from sparks, molten metal splatter, and radiant heat. Unlike regular fabrics, they won't catch fire or melt under extreme temperatures.

Key Benefits for Your Workshop

1. Fire Prevention:They stop welding sparks from igniting flammable materials nearby. Place them over wood floors or near chemicals.2. Surface Protection:Cover valuable equipment or vehicles to prevent heat damage.3. Versatility:Use them horizontally as floor coverings or vertically as welding curtains.4. Reusability:Unlike disposable covers, fiberglass welding blankets last through hundreds of uses.

Temperature Resistance Explained

Standard fiberglass welding blankets withstand continuous exposure to 1000°F (538°C) and brief contact up to 2000°F (1093°C). The exact rating depends on:- Fiberglass weave density (higher = better protection)- Silicone coating (improves heat reflection)- Thickness (typically 1/16" to 1/8")Always check manufacturer specifications for your specific welding applications.

Choosing the Right Blanket

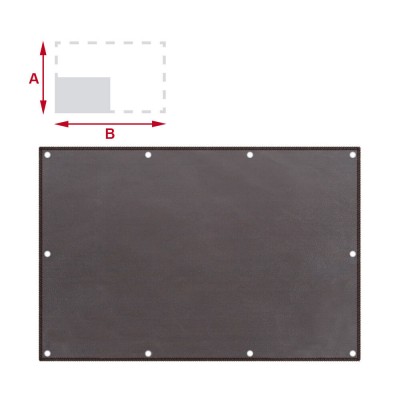

Consider these factors when selecting fiberglass welding blankets:Size:Common options range from 3'x3' for small jobs to 12'x12' for large projects.Weight:Heavy-duty blankets (18+ oz/sq yd) offer maximum durability.Color:Black resists stains; bright colors improve visibility.Edge Treatment:Stitched edges with grommets allow secure hanging.

Proper Usage Tips

1. Inspect First:Check for tears or thin spots before each use.2. Overlap Coverage:When covering large areas, overlap blankets by 6+ inches.3. Secure Properly:Use hooks or clamps to prevent shifting during work.4. Clean Carefully:Shake off debris; wash only if manufacturer-approved.5. Store Flat:Folding creates weak points over time.

Maintenance for Longevity

To extend your fiberglass welding blanket's life:- Remove metal spatter with a putty knife (don't scrape aggressively)- Air out after use to eliminate moisture buildup- Repair small holes with high-temperature silicone sealant- Replace when more than 10% of the surface shows significant wear

Safety Precautions

While fiberglass welding blankets are protective, remember:- They don't replace proper PPE (always wear gloves/face shields)- Some fiberglass fabrics shed particles—wear long sleeves during handling- Never use near open flames (only for spark/slag protection)- Keep away from children due to potential fiber irritation

Alternative Materials Comparison

Leather:More durable but heavier and expensive

Where to Use Them

Beyond welding, fiberglass blankets work for:- Forge work- Foundry operations- Fireplace spark protection- Hot pipe insulation- Automotive exhaust system repairs

Final Recommendations

Invest in at least two fiberglass welding blankets—one for floor coverage and another for vertical protection. For MIG/TIG welding, choose silicone-coated options for better slag resistance. Always buy from reputable safety equipment suppliers to ensure proper heat ratings.