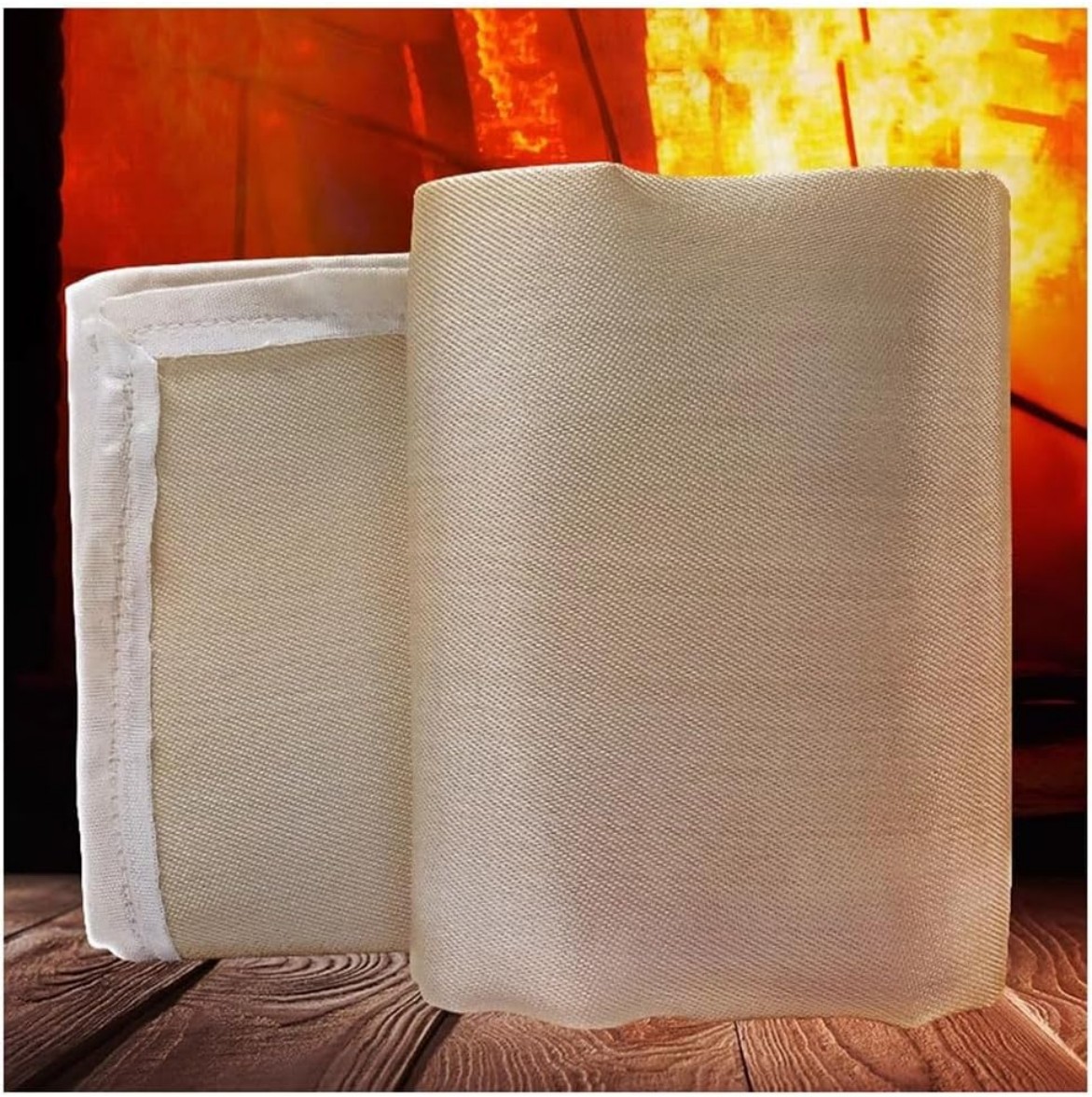

Silica Cloth Welding Blanket: Ultimate Protection for High-Temperature Work

This guide explains how silica cloth welding blankets protect against sparks and extreme heat. You'll learn their benefits, proper usage, and how they outperform other welding protection materials in durability and safety.

What Is a Silica Cloth Welding Blanket?

Silica cloth welding blankets are specialized protective covers made from woven silica fibers. These high-temperature resistant fabrics withstand continuous exposure to 1800°F (982°C) and brief spikes to 3000°F (1649°C). Unlike ordinary welding blankets, silica cloth versions offer superior heat reflection and won't melt or drip when exposed to welding sparks.

Key Benefits of Using Silica Cloth Welding Blankets

When you choose a silica cloth welding blanket, you get multiple advantages:

- Exceptional heat resistance- Protects surrounding areas from welding arcs and molten metal splatter

- Non-combustible material- Won't catch fire or support flame spread

- Flexible protection- Easily drapes over irregular shapes and surfaces

- Reusable durability- Lasts significantly longer than fiberglass alternatives

- Chemical resistance- Withstands exposure to most acids and alkalis

How to Properly Use Your Silica Cloth Welding Blanket

To maximize protection and lifespan of your silica cloth welding blanket:

- Inspect for damage before each use - replace if you find significant tears

- Position the blanket to cover all vulnerable areas within 35 feet of welding

- Secure edges with non-combustible weights or clamps to prevent shifting

- Allow proper clearance (minimum 12 inches) from the actual welding point

- Clean with compressed air or soft brush after cooling completely

Silica Cloth vs. Other Welding Blanket Materials

Compared to common alternatives, silica cloth welding blankets offer distinct advantages:

| Material | Max Temperature | Melting Risk | Typical Lifespan |

|---|---|---|---|

| Silica Cloth | 3000°F (1649°C) | None | 3-5 years |

| Fiberglass | 1000°F (538°C) | Possible | 6-12 months |

| Leather | 400°F (204°C) | Chars | 1-2 years |

Choosing the Right Silica Cloth Welding Blanket

Consider these factors when selecting your silica cloth welding blanket:

- Thickness- 1/8" for general welding, 1/4" for heavy industrial use

- Size- Common options from 3'x3' to 12'x12'

- Reinforcement- Stitched edges and grommets for hanging increase durability

- Certifications- Look for OSHA and NFPA compliance markings

Maintenance Tips for Long-Lasting Performance

Proper care extends your silica cloth welding blanket's effectiveness:

- Store flat or rolled in a dry, clean area

- Never fold sharply - this weakens the silica fibers

- Remove metal spatter with a wooden or plastic scraper

- Wash only when necessary using mild detergent and cold water

- Inspect stitching and grommets monthly

Common Applications Beyond Welding

While designed for welding, silica cloth blankets serve multiple high-heat applications:

- Foundry work and metal casting protection

- Fire curtain in industrial settings

- Thermal insulation for piping and equipment

- Spark containment during grinding operations

- Emergency fire blankets in workshops

Safety Precautions When Using Silica Cloth Blankets

Remember these critical safety measures:

- Always wear proper PPE (gloves, face shield) when handling hot blankets

- Never use damaged blankets - small tears can rapidly expand under heat stress

- Ensure adequate ventilation when welding near silica cloth barriers

- Keep oxygen cylinders and fuel sources away from blanket areas

- Train all workers on proper deployment and emergency procedures

Where to Buy Quality Silica Cloth Welding Blankets

Purchase from reputable industrial safety suppliers who provide:

- Detailed product specifications

- Material composition documentation

- Temperature resistance certifications

- Custom sizing options when needed