Essential Welding Blanket Requirements for Safe Arc Welding Operations

Summary:A welding blanket is essential for arc welding safety. It protects against sparks, slag, and heat damage. Choose fire-resistant materials like fiberglass or silica for optimal protection. Proper use reduces workplace hazards significantly.

Why You Need a Welding Blanket for Arc Welding

When performing arc welding, a welding blanket isn't just optional - it's required for safety. The intense heat (up to 10,000°F) and flying sparks from arc welding can easily ignite nearby materials. A proper welding blanket acts as a protective barrier, containing these hazards within your work area.

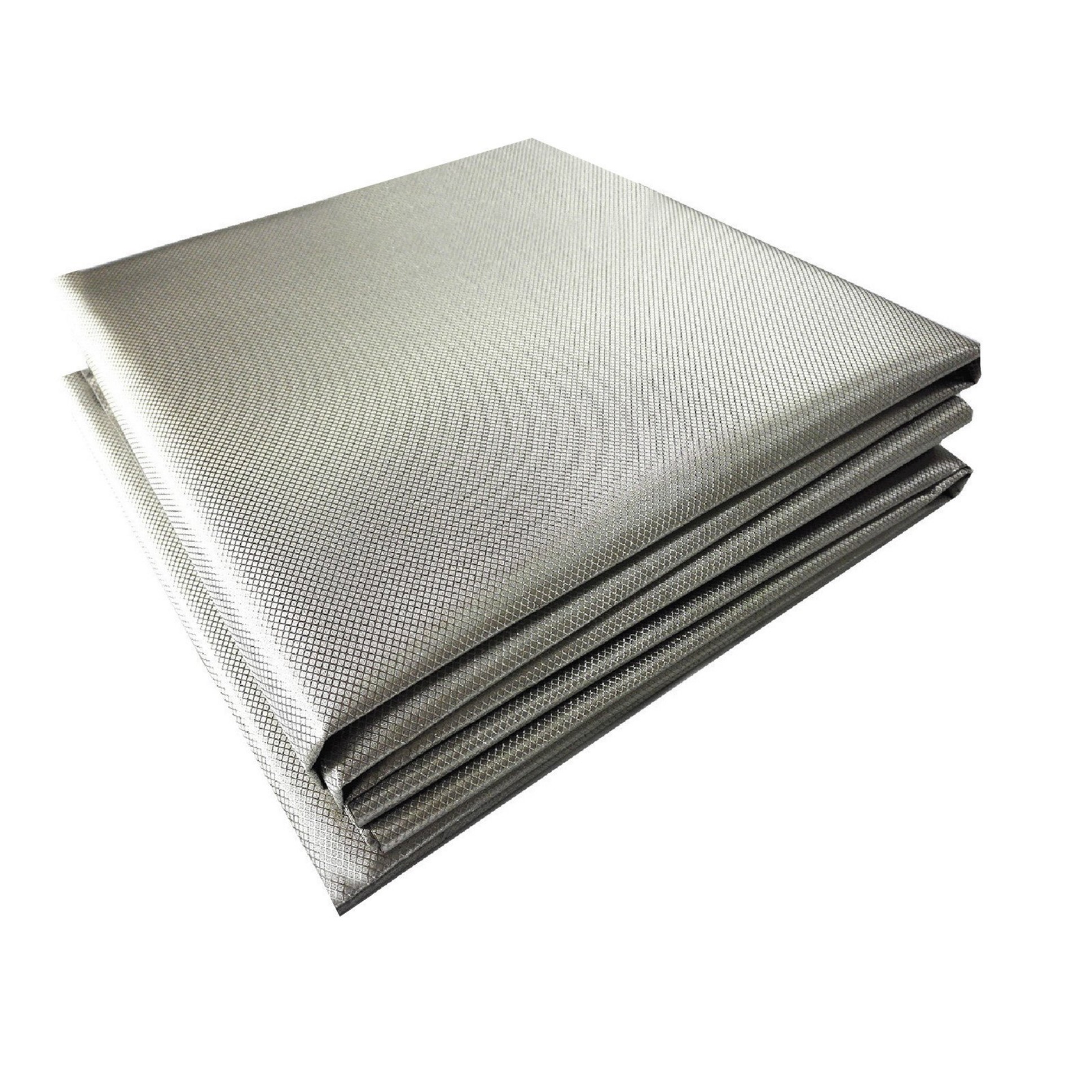

Key Features of Quality Welding Blankets

Not all welding blankets meet the requirements for arc welding. Look for these essential characteristics:

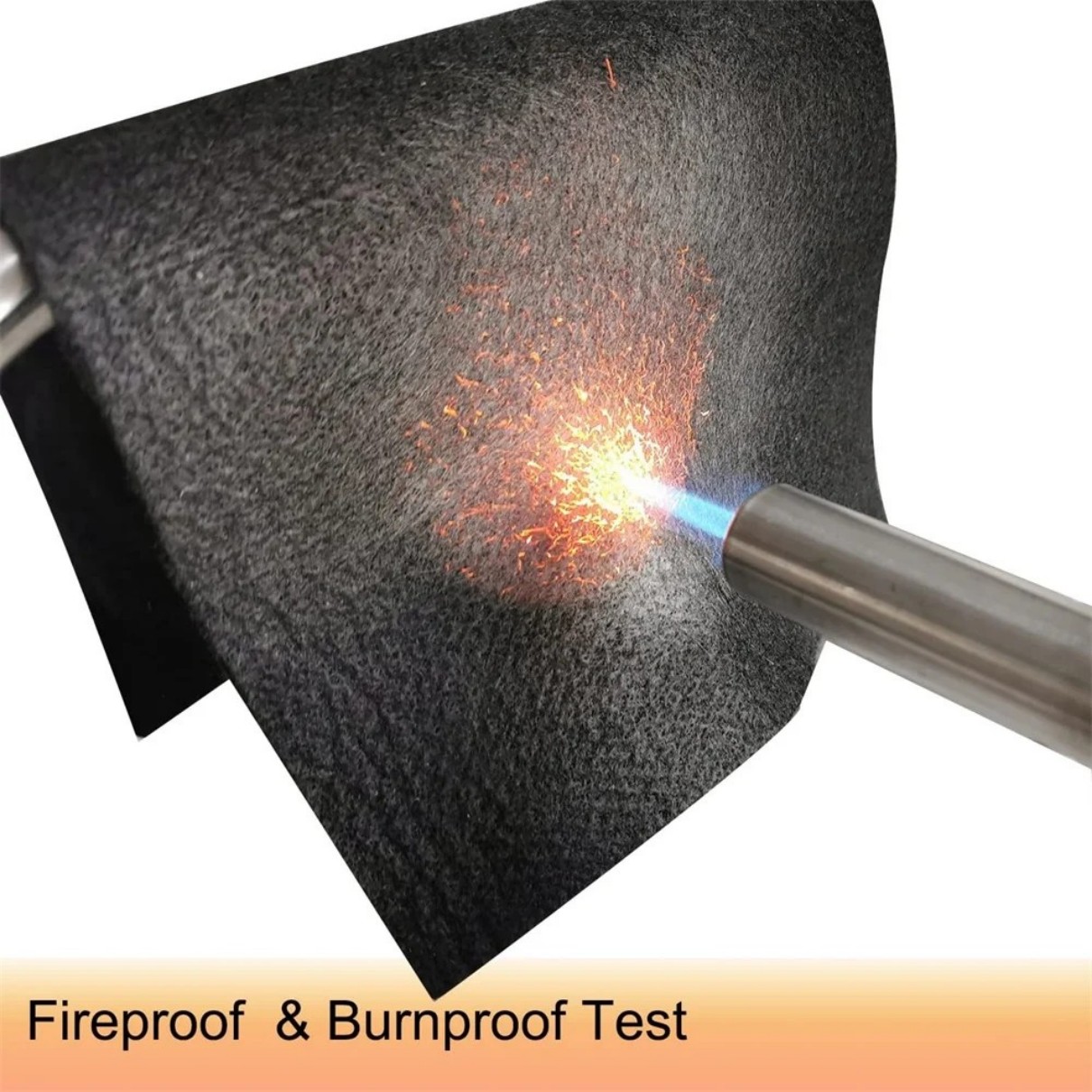

- Fire resistance:Must withstand direct flame contact without burning

- Heat tolerance:Should handle temperatures up to 2000°F continuously

- Material quality:Fiberglass or silica fabrics offer the best protection

- Proper sizing:Coverage should extend at least 2 feet beyond your work area

- Durability:Reinforced edges prevent fraying from repeated use

How to Use Your Welding Blanket Correctly

Simply having a welding blanket isn't enough - proper placement matters. Follow these steps:

- Cover all flammable surfaces within 35 feet of your welding area

- Secure the blanket with non-flammable weights or clamps

- Overlap multiple blankets by at least 6 inches if needed

- Inspect for damage before each use - replace if you find holes

- Keep a fire extinguisher nearby as additional protection

Welding Blanket Materials Compared

Different materials offer varying levels of protection for arc welding:

| Material | Max Temperature | Pros | Cons |

|---|---|---|---|

| Fiberglass | 1000°F | Affordable, flexible | Lower heat resistance |

| Silica | 2000°F | Superior heat protection | More expensive |

| Leather | 500°F | Durable | Heavy, limited protection |

Maintenance and Safety Tips

To ensure your welding blanket remains effective:

- Clean regularly with compressed air - never wash with water

- Store flat or rolled - never fold, as this weakens fibers

- Replace immediately if you notice discoloration or stiffening

- Never use a welding blanket as personal protective equipment (PPE)

- Combine with other safety measures like ventilation and proper PPE

Common Mistakes to Avoid

Even experienced welders sometimes make these errors with welding blankets:

- Using blankets that are too small for the work area

- Placing blankets too close to the welding arc (keep at least 3 feet away)

- Reusing damaged blankets with holes or thin spots

- Assuming one blanket type works for all welding processes

- Forgetting to protect vertical surfaces near the work area

When to Upgrade Your Welding Blanket

Consider replacing your welding blanket if:

- You're working with higher amperage than your blanket's rating

- You notice reduced flexibility or increased stiffness

- Your welding projects have changed (larger scale or different metals)

- The blanket has visible damage or discoloration

- You're required to meet new safety regulations

Remember, a proper welding blanket required for arc welding isn't just about compliance - it's about protecting your workspace, your equipment, and most importantly, yourself. Invest in quality protection that matches your specific welding needs.