Welding Blanket Roll: Durable Heat Protection for Industrial Workspaces

Summary:A welding blanket roll provides essential heat and spark protection in industrial environments. This guide explains its materials, uses, benefits, and selection criteria to help you choose the right protection for your workspace.

What Is a Welding Blanket Roll?

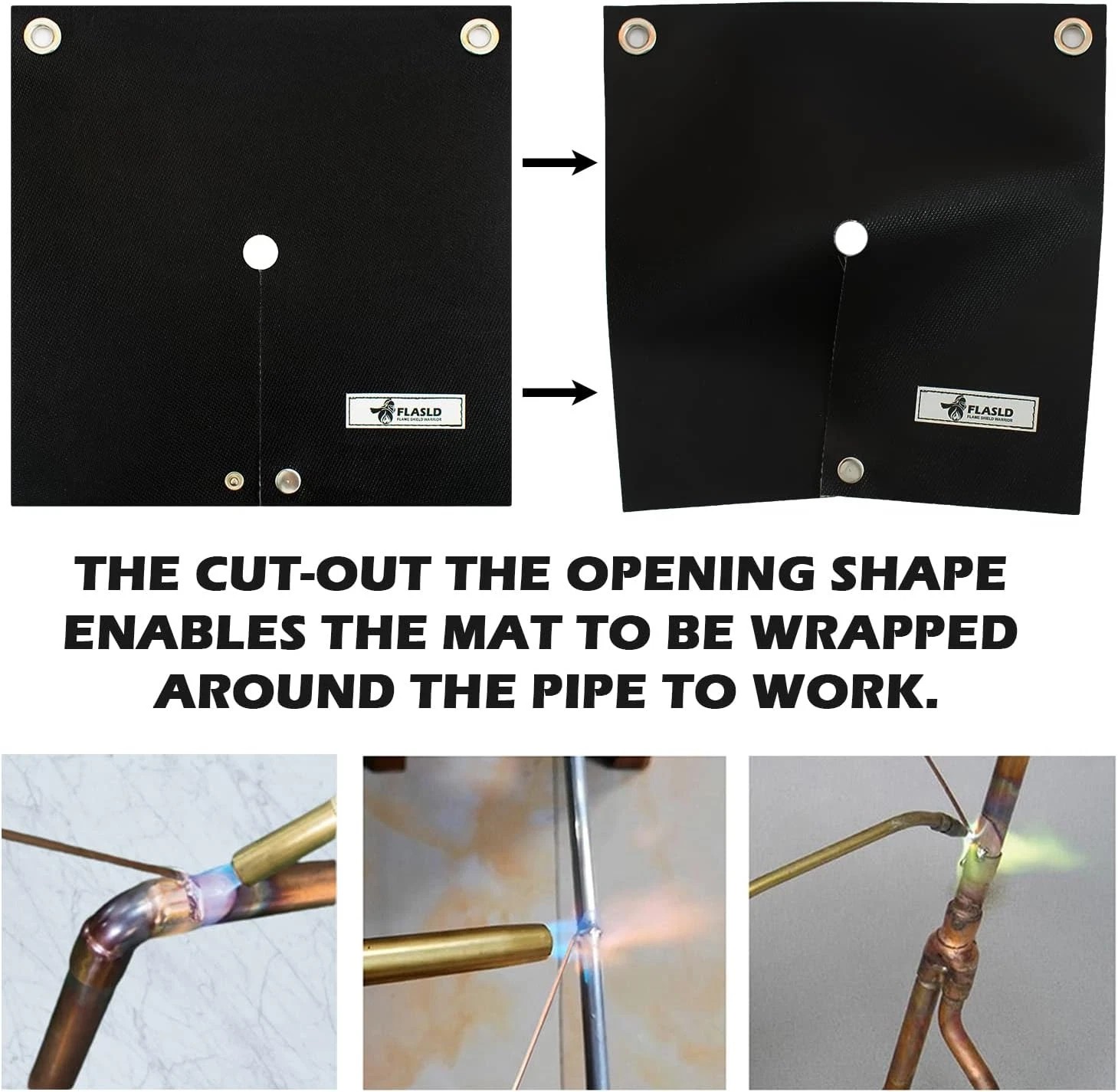

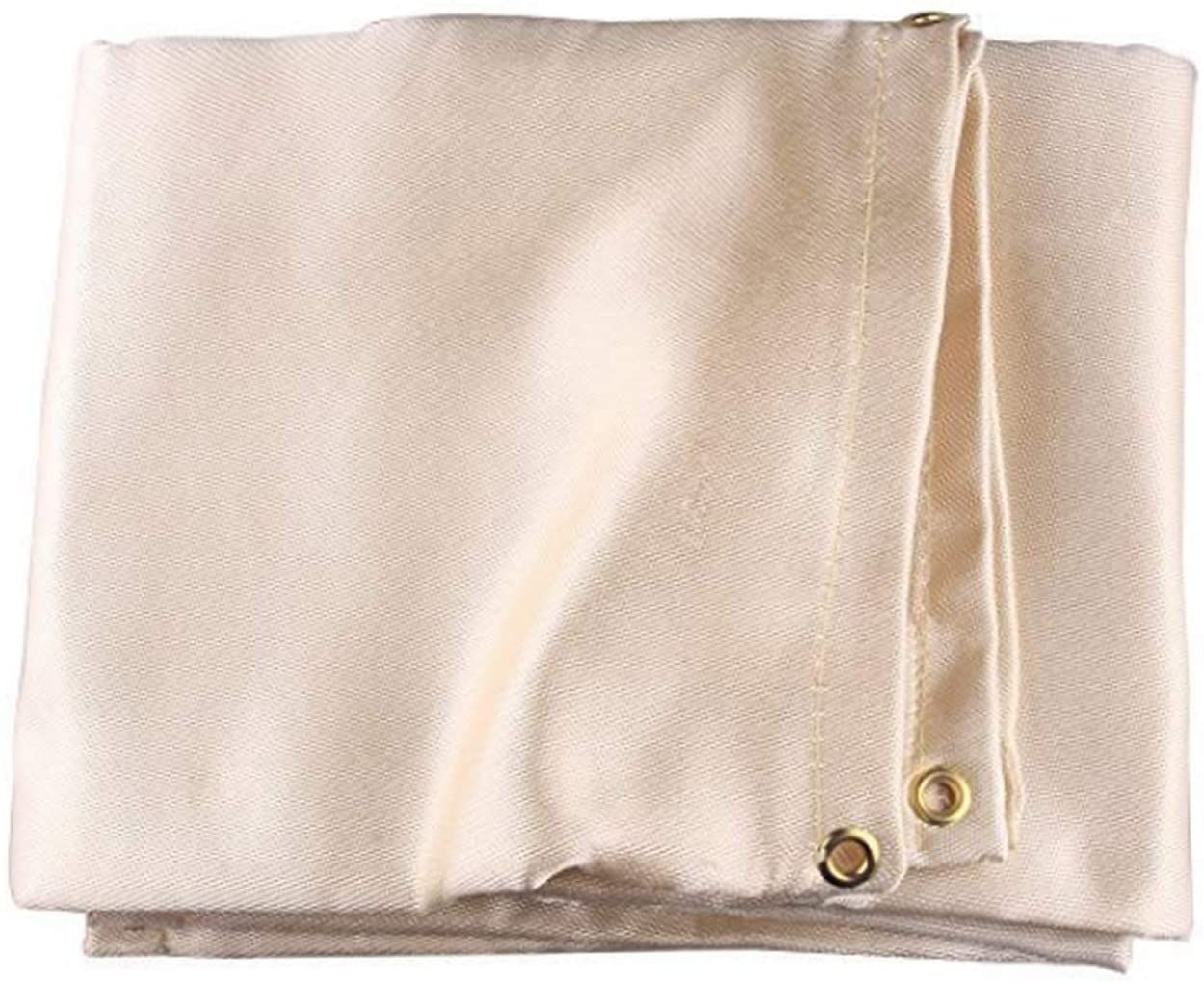

A welding blanket roll is a flexible, heat-resistant protective material designed to shield surfaces from sparks, slag, and extreme temperatures during welding operations. Unlike pre-cut blankets, the roll format allows you to customize sizes for different applications. These blankets typically come in widths from 36" to 72" and lengths up to 50 feet.

Key Materials and Construction

Quality welding blanket rolls are made from specialized materials that withstand temperatures up to 3,000°F:

- Fiberglass:The most common base material, often coated with silicone for extra durability

- Silica:Offers superior heat resistance for high-temperature applications

- Ceramic fibers:Used in premium blankets for extreme conditions

The best welding blanket rolls feature double-stitched edges and reinforced grommets for secure installation.

Primary Applications

Welding blanket rolls serve multiple protective functions:

- Shielding floors and walls in welding shops

- Protecting vehicles during auto body repairs

- Covering sensitive equipment near hot work areas

- Creating temporary welding curtains

- Safeguarding wooden structures on construction sites

Benefits Over Standard Welding Blankets

The roll format offers distinct advantages:

- Custom sizing:Cut exactly what you need for each job

- Cost efficiency:Reduce waste by using only required material

- Storage convenience:Takes less space than multiple pre-cut blankets

- Versatility:Adapt to irregular shapes and large areas

How to Choose the Right Welding Blanket Roll

Consider these factors when selecting:

- Temperature rating:Match to your specific welding processes

- Thickness:Thicker blankets (1/8" or more) last longer

- Material composition:Fiberglass for general use, silica for extreme heat

- Width options:Ensure it covers your typical work areas

- Certifications:Look for OSHA-compliant products

Proper Use and Maintenance

To maximize your welding blanket roll's lifespan:

- Inspect regularly for tears or excessive wear

- Clean with compressed air or soft brush (never wash)

- Store rolled up in a dry, clean area

- Replace when fibers become brittle or frayed

Always overlap sections by at least 6 inches when covering large areas for complete protection.

Safety Considerations

While welding blanket rolls provide excellent protection, remember:

- They are heat resistant, not heat proof - avoid direct flame contact

- Combine with other PPE like gloves and face shields

- Ensure proper ventilation when welding near blanket materials

- Never use damaged blankets - replace immediately

Where to Buy Quality Welding Blanket Rolls

Purchase from reputable industrial safety suppliers or welding equipment specialists. Look for manufacturers with:

- Clear temperature ratings and specifications

- Positive customer reviews

- Reasonable lead times for custom orders

- Good return policies for defective products

Investing in a high-quality welding blanket roll protects your workspace, equipment, and most importantly - your workers. The flexibility and customization options make it an essential safety tool for any welding operation.