Welding Cloth Blanket: Essential Protection for Safe Welding Operations

A welding cloth blanket protects your workspace from sparks, slag, and heat during welding. This guide explains its materials, uses, benefits, and how to choose the right one for your projects while maintaining safety standards.

What Is a Welding Cloth Blanket?

A welding cloth blanket is a flame-resistant protective covering made from specially treated materials. You use it to shield floors, walls, equipment, and surrounding areas from welding sparks and molten metal splatter. Unlike regular blankets, welding cloth blankets resist temperatures up to 1,800°F (982°C) without catching fire.

Key Materials in Welding Blankets

Quality welding cloth blankets typically combine these materials:

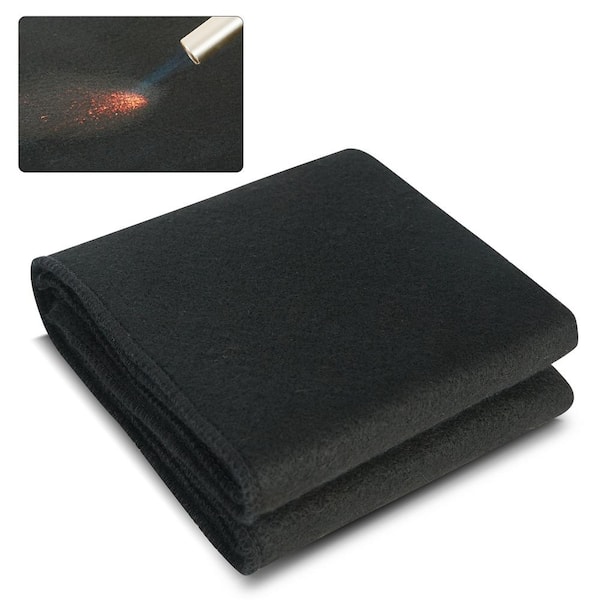

- Fiberglass:The most common base material, offering excellent heat resistance

- Silica:For ultra-high temperature applications

- Vermiculite coatings:Enhance fire resistance

- Rubberized coatings:Add durability and flexibility

When to Use a Welding Cloth Blanket

You should always use a welding cloth blanket when:

- Working near flammable materials

- Welding in confined spaces

- Protecting finished surfaces from spatter

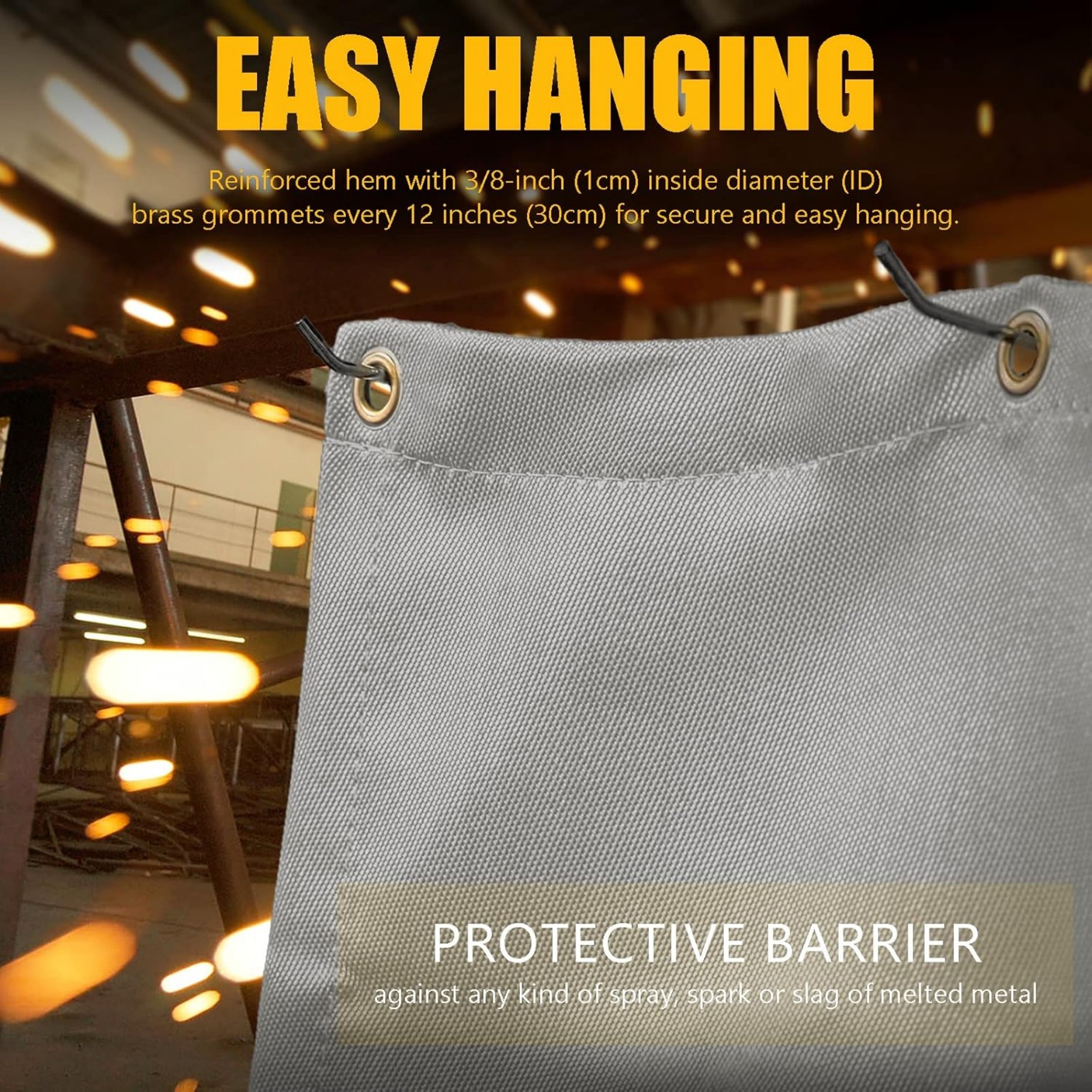

- Creating temporary welding curtains

- Covering equipment that can't be moved

Benefits You Get From Using Welding Blankets

Proper use of welding cloth blankets gives you these advantages:

- Fire prevention:Reduces workshop fire risks by 80% according to safety studies

- Surface protection:Prevents damage to floors and walls from sparks

- Cost savings:Eliminates frequent replacements of damaged materials

- Versatility:Can be cut to size for different applications

- Reusability:High-quality blankets last for years with proper care

Choosing the Right Welding Cloth Blanket

Follow these guidelines when selecting your welding blanket:

- Temperature rating:Must exceed your maximum working temperature

- Size:Should cover all vulnerable areas with overlap

- Thickness:Thicker blankets (1/8"+) offer better protection for heavy welding

- Certifications:Look for OSHA, ANSI, or NFPA compliance

- Color coding:Some industries require specific colors for different protection levels

Proper Maintenance of Your Welding Blanket

To extend your welding cloth blanket's lifespan:

- Shake off slag and debris after each use

- Store flat or rolled (never folded) to prevent fiber damage

- Inspect regularly for holes or thinning areas

- Clean with compressed air - never wash with water

- Replace when more than 10% of the surface shows wear

Safety Tips When Using Welding Blankets

Remember these safety practices:

- Always wear proper PPE beneath the blanket when welding

- Secure the blanket properly - don't let it hang loosely

- Keep at least 18 inches clearance from the actual weld point

- Never use damaged or contaminated blankets

- Have a fire extinguisher nearby as secondary protection

Common Mistakes to Avoid

Steer clear of these errors with welding cloth blankets:

- Using regular tarps or blankets as substitutes

- Overlapping multiple thin blankets instead of using one proper thickness

- Ignoring manufacturer's temperature limits

- Folding rather than rolling for storage

- Using the same blanket for both welding and grinding

A quality welding cloth blanket is one of your most valuable workshop safety investments. By choosing the right product and using it correctly, you protect both your work environment and yourself from welding hazards. Always prioritize certified products from reputable manufacturers for guaranteed protection.