Welding Warm Blankets: Essential Protection for Safe & Efficient Welding Jobs

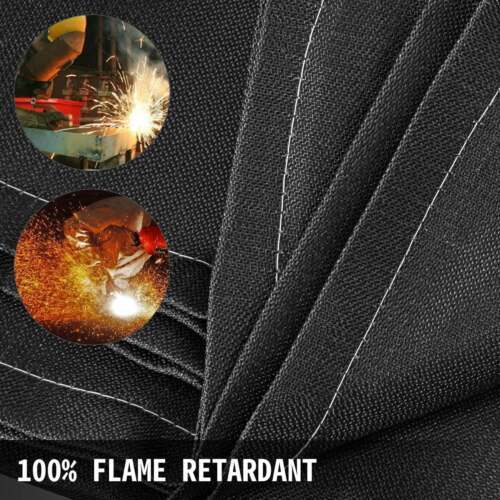

Welding warm blankets protect surfaces from sparks, slag, and heat damage during welding projects. These fire-resistant covers are essential for workplace safety and preventing costly damage to floors, equipment, and surrounding materials.

Why You Need Welding Warm Blankets

When you're welding, sparks and molten metal can travel several feet from your work area. Standard blankets or tarps won't protect against these extreme temperatures. Welding warm blankets are specially designed to:

- Withstand temperatures up to 1,800°F (982°C)

- Prevent fire hazards by containing sparks and slag

- Protect floors, walls, and valuable equipment

- Create safe work zones in confined spaces

Key Features of Quality Welding Blankets

Not all welding blankets offer the same level of protection. Look for these essential features when choosing warm blankets for welding:

- Material:Fiberglass or silica fabric with fire-resistant coatings

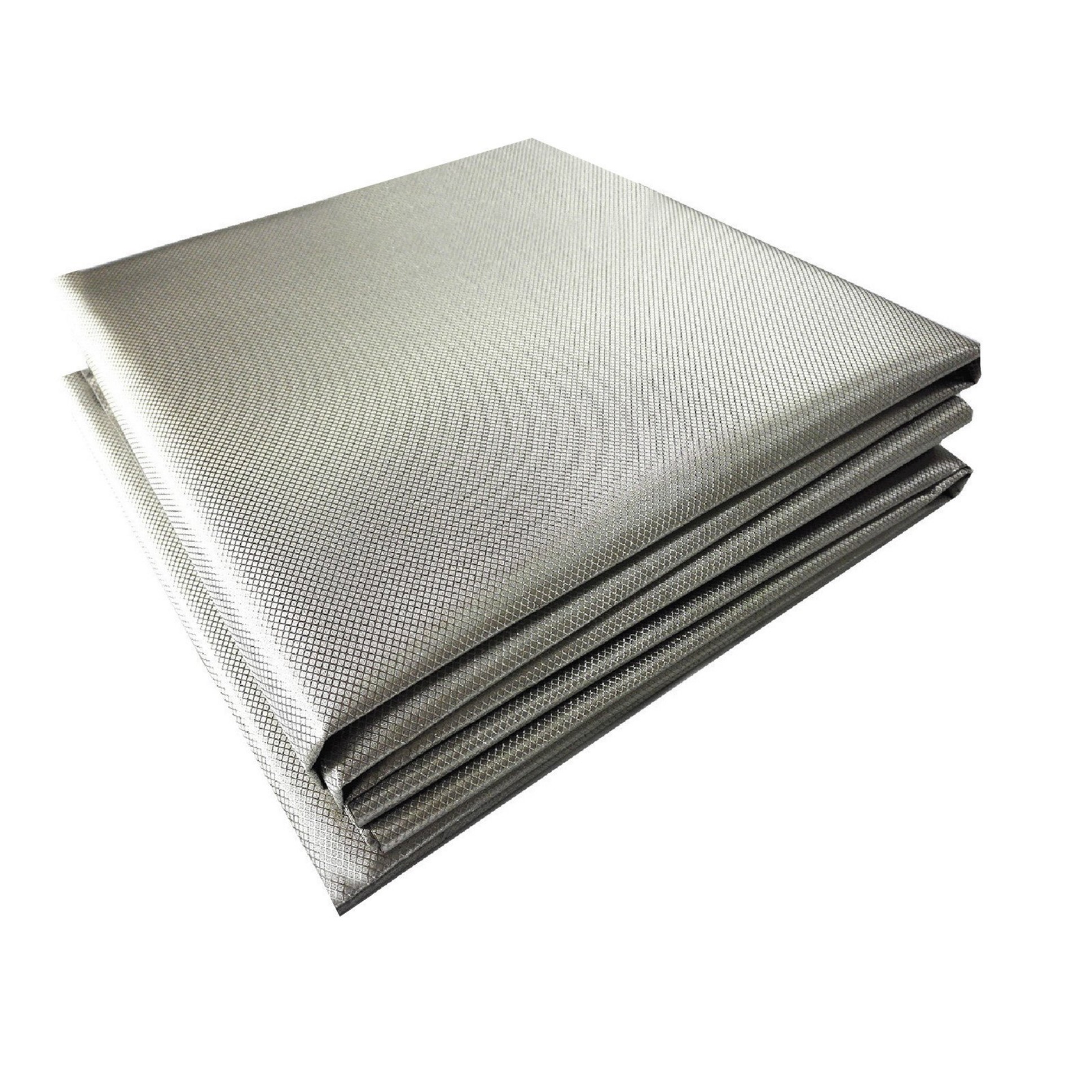

- Thickness:Minimum 1/16 inch (1.6mm) for adequate protection

- Size:Various sizes from 3'x3' to 12'x12' for different projects

- Durability:Reinforced edges and grommets for secure placement

- Flexibility:Soft enough to drape over irregular surfaces

How to Use Welding Warm Blankets Properly

To get maximum protection from your welding blanket:

- Cover all surfaces within at least 10 feet of your welding area

- Overlap multiple blankets if needed for larger coverage

- Secure edges with weights or clamps to prevent shifting

- Inspect for damage before each use - replace if there are holes or fraying

- Store properly by folding neatly when not in use

Welding Blanket Applications Beyond Basic Protection

While their primary purpose is safety, warm blankets for welding have several other practical uses:

- Heat containment:Keep heat in your work area during cold weather welding

- Curing cover:Maintain even temperatures for weld cooling

- Temporary curtains:Create welding screens in shared workspaces

- Emergency repairs:Use as temporary patches for damaged insulation

Maintenance Tips for Long-Lasting Performance

Proper care extends the life of your welding warm blankets:

- Shake off slag and debris after each use

- Wash only when necessary using mild soap and water

- Never use bleach or harsh chemicals that degrade fibers

- Air dry completely before storage to prevent mildew

- Store in a dry place away from direct sunlight

Choosing Between Fiberglass and Silica Welding Blankets

The two main types of warm blankets for welding each have advantages:

Fiberglass blankets:

- More affordable option

- Good for general purpose welding

- Available in various colors for different temperature ratings

Silica blankets:

- Higher temperature resistance (up to 2,000°F)

- More flexible and drapes better

- Longer lifespan with proper care

- Better for critical applications

Safety Considerations When Using Welding Blankets

While welding warm blankets significantly improve safety, remember:

- They don't replace proper personal protective equipment (PPE)

- Never leave hot blankets in contact with flammable materials

- Allow blankets to cool completely before handling

- Wear gloves when handling used blankets to avoid fiberglass irritation

- Follow all standard welding safety protocols

Investing in quality warm blankets for welding protects your work area, prevents costly damage, and creates a safer environment for you and your coworkers. Choose the right type and size for your specific welding applications, and maintain them properly for years of reliable service.