How Insulated Welding Blankets Protect Your Workspace and Improve Safety

Summary:Insulated welding blankets are essential safety tools that protect surfaces from sparks, slag, and heat during welding. They improve workspace safety, prevent fire hazards, and maintain surface integrity while being durable and easy to use.

What Are Insulated Welding Blankets?

Insulated welding blankets are specialized protective covers made from heat-resistant materials like fiberglass, silica, or ceramic fabrics. When you're welding, these blankets shield surrounding areas from sparks, molten metal splatter, and radiant heat that could cause damage or fires.

Unlike regular tarps, insulated welding blankets can withstand temperatures up to 2000°F (1093°C) depending on the material. You'll find them in various sizes and thicknesses to match different welding applications.

Key Benefits of Using Insulated Welding Blankets

When you use insulated welding blankets properly, they offer multiple advantages:

- Fire prevention:They create a barrier that stops sparks from igniting flammable materials

- Surface protection:Keep floors, walls, and equipment safe from heat damage and spatter

- Heat containment:Reduce radiant heat that could affect nearby workers or materials

- Reusable protection:High-quality blankets last through hundreds of welding jobs

- Versatility:Useful for welding, grinding, cutting, and other hot work applications

Choosing the Right Insulated Welding Blanket

Not all welding blankets offer the same protection. Consider these factors when selecting yours:

Temperature Rating

Match the blanket's maximum temperature rating to your welding process. MIG and TIG welding typically require blankets rated for 1000-2000°F, while plasma cutting may need higher ratings.

Material Composition

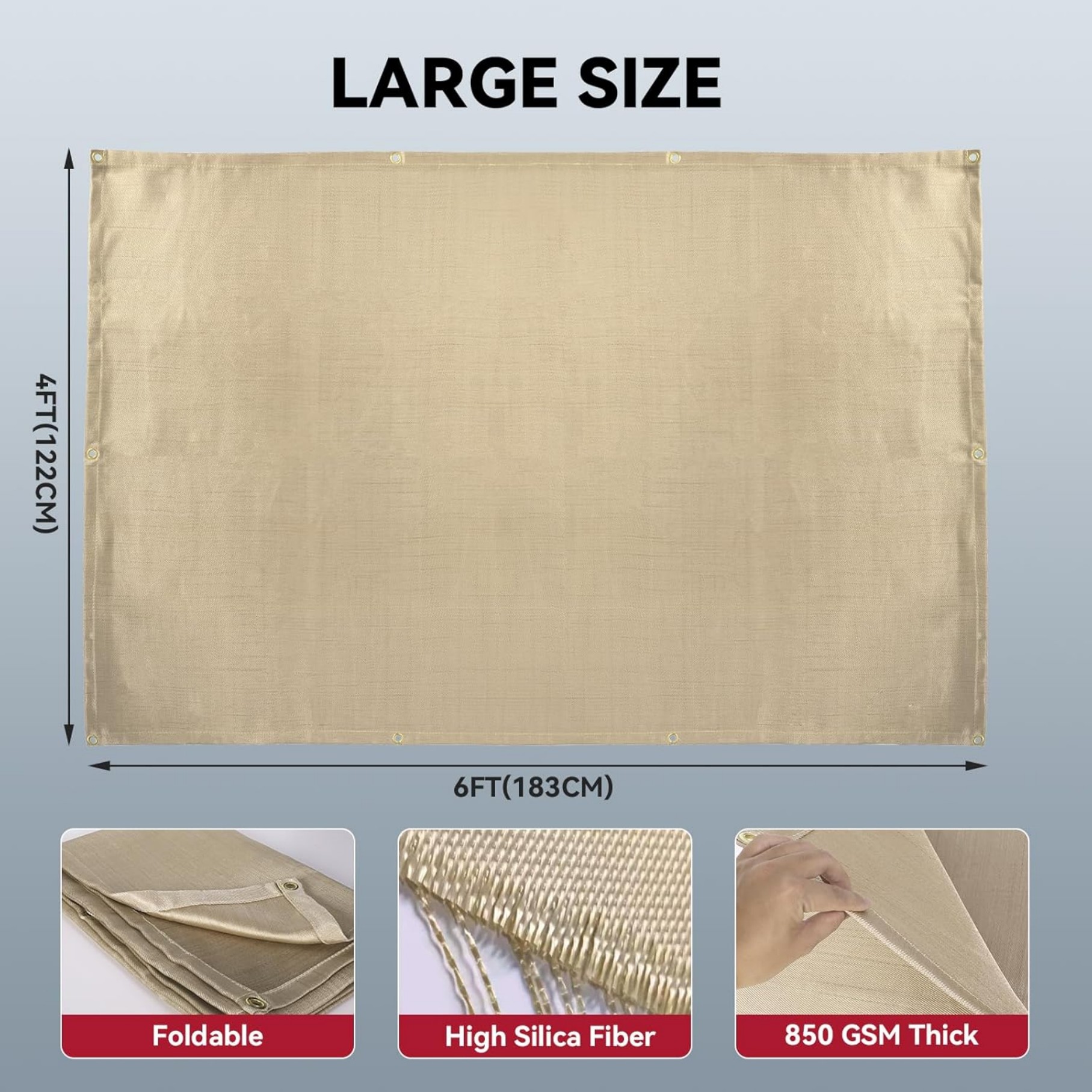

Fiberglass is common for general welding, while silica or ceramic options provide superior protection for high-heat applications. Some premium blankets combine multiple materials for optimal performance.

Size and Coverage

Measure your work area to ensure complete coverage. Standard sizes range from 3'x3' to 10'x10', with custom options available for large projects.

Attachment Methods

Look for grommets, hooks, or Velcro straps that help secure the blanket in place during use. Proper anchoring prevents dangerous gaps in protection.

Proper Use and Maintenance

To get the most from your insulated welding blanket:

- Inspect before each use for tears, holes, or excessive wear

- Position the blanket to cover all vulnerable areas completely

- Secure edges to prevent movement during work

- Allow the blanket to cool completely before handling

- Clean with compressed air or gentle brushing (never wash with water)

- Store flat or rolled in a dry, clean area when not in use

Safety Considerations

While insulated welding blankets significantly improve safety, remember:

- They don't replace proper personal protective equipment (PPE)

- Never use damaged blankets - replace them immediately

- Monitor for heat buildup in confined spaces

- Keep fire extinguishers accessible when welding

- Follow all standard welding safety protocols

Applications Beyond Welding

Insulated welding blankets have uses in many industries:

Automotive:Protecting vehicle interiors during exhaust work or frame repairsConstruction:Shielding finished surfaces during metal cutting or weldingManufacturing:Containing heat in foundries or metal fabrication shopsMarine:Preventing deck damage during ship repairsEmergency Services:Temporary heat barriers during firefighting operations

Investing in Quality Protection

While cheaper alternatives might seem appealing, high-quality insulated welding blankets provide better protection and last longer. Look for reputable brands that meet industry safety standards and offer clear specifications about temperature ratings and durability.

Remember that proper welding protection saves money in the long run by preventing costly damage to equipment and facilities while keeping your team safe from preventable accidents.