Welding Blanket Specifications: Key Features and Selection Guide

Summary:This guide explains welding blanket specifications, helping you choose the right protection for welding projects. Learn about materials, temperature ratings, sizes, and safety standards.

Understanding Welding Blanket Specifications

When selecting a welding blanket, specifications determine its effectiveness. You need to consider material composition, temperature resistance, size options, and compliance with safety standards. These factors directly impact your protection against sparks, slag, and heat during welding operations.

Material Types in Welding Blanket Specifications

Welding blanket specifications typically list these common materials:

- Fiberglass:Most common, withstands 1000°F (538°C), flexible

- Silica:Handles 1800°F (982°C), more rigid

- Ceramic:For extreme heat up to 3000°F (1649°C)

- Carbon Fiber:Lightweight with high heat resistance

Your choice depends on the welding process and temperatures you'll encounter. Fiberglass meets most general welding needs, while specialty processes like plasma cutting may require silica or ceramic.

Temperature Ratings Explained

Welding blanket specifications always include temperature ratings. These indicate:

- Continuous exposure rating:Maximum temperature for prolonged use

- Peak temperature:Short-term tolerance for sparks and splatter

For MIG welding, look for blankets rated at least 500°F above your working temperature. TIG welding typically requires higher ratings due to concentrated heat.

Size and Thickness Considerations

Standard welding blanket specifications include:

| Size (ft) | Thickness (mm) | Best For |

|---|---|---|

| 3x3 | 1-2 | Small bench work |

| 6x6 | 2-3 | General purpose |

| 8x8 | 3-4 | Large projects |

| Custom | Varies | Special applications |

Thicker blankets (3mm+) offer better protection but reduce flexibility. Consider your workspace dimensions when choosing sizes.

Safety Standards in Welding Blanket Specifications

Reputable welding blankets meet these standards:

- OSHA 1910.252 (welding safety requirements)

- NFPA 701 (flame resistance)

- ASTM D6413 (flame retardant textiles)

Always verify compliance with these standards in the product specifications. Non-compliant blankets may fail when you need protection most.

Maintenance and Care Specifications

Proper maintenance extends your welding blanket's life:

- Inspect for damage before each use

- Clean with compressed air - never wash

- Store flat or rolled, not folded

- Replace when fibers become brittle

Most quality welding blankets last 1-3 years with proper care, depending on usage frequency.

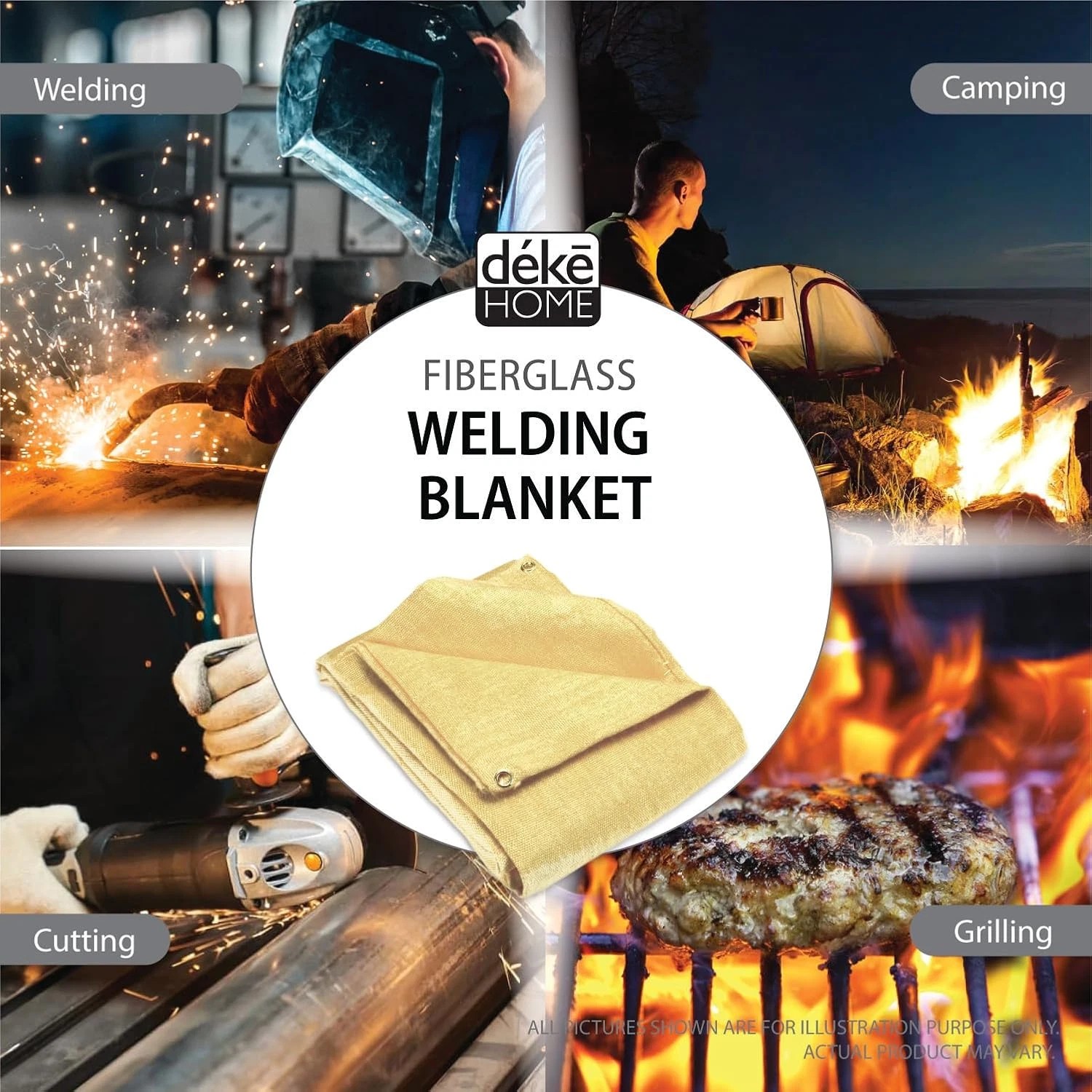

Specialty Welding Blanket Options

Advanced welding blanket specifications may include:

- Welding curtains:Transparent protection with UV filtering

- Multi-layer designs:Combine different materials for varied protection

- Reinforced edges:Grommets or metal bindings for hanging

- Chemical-resistant:For hazardous material environments

These options address specific workplace requirements beyond basic spark protection.

Making Your Selection

When reviewing welding blanket specifications, ask:

- What welding processes will I use?

- What are my maximum temperature needs?

- What size fits my workspace?

- What safety standards apply to my workplace?

- What's my budget for quality protection?

Investing in the right welding blanket prevents costly damage and ensures safety. Never compromise on specifications that protect you from welding hazards.