Flexible Blanket Fire Protection: Essential Safety for Industrial Applications

Summary:Flexible blanket fire protection provides portable, heat-resistant barriers for emergency fire containment. These specialized blankets suppress flames, protect equipment, and create safe evacuation routes in industrial settings.

What Is Flexible Blanket Fire Protection?

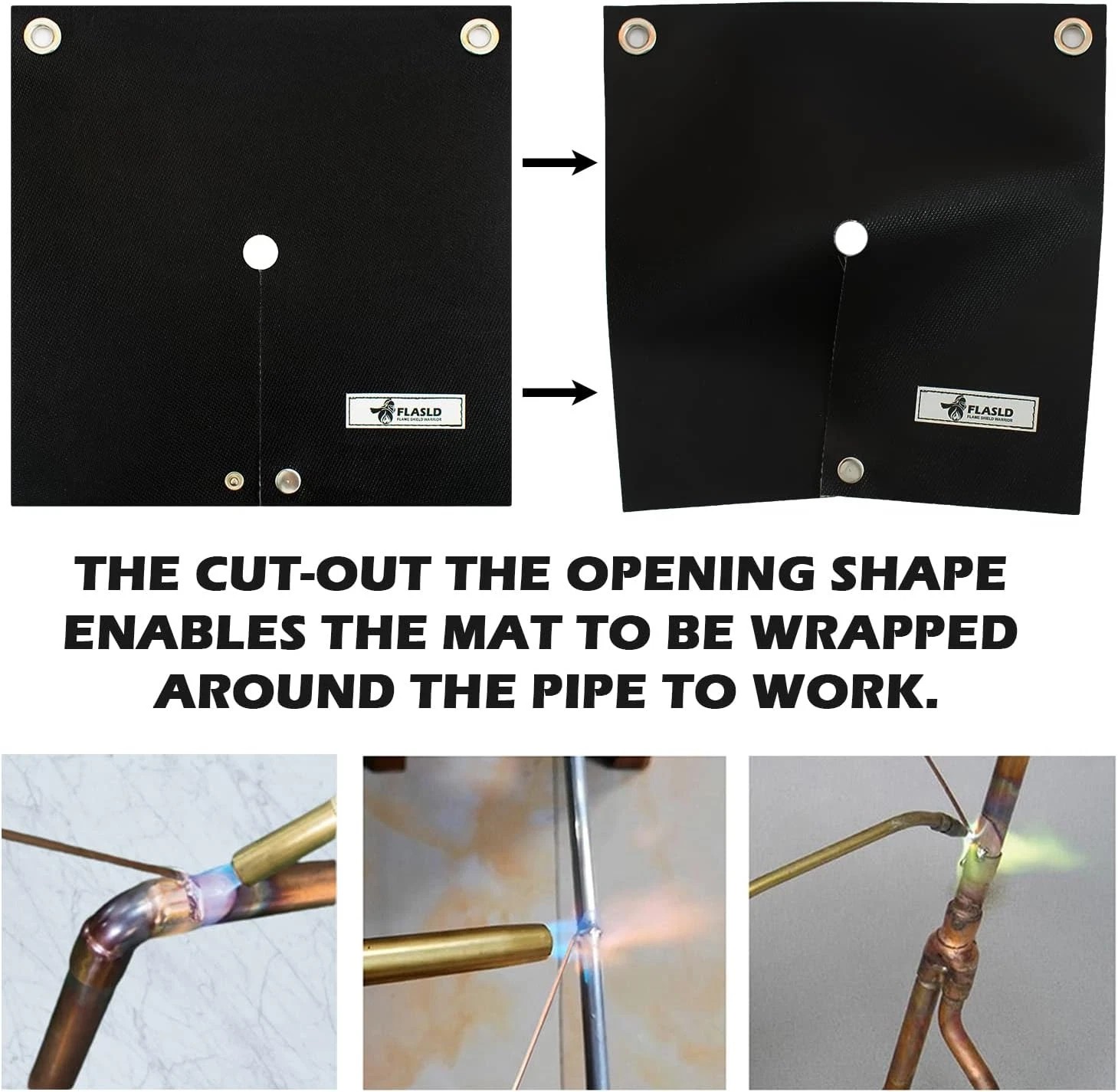

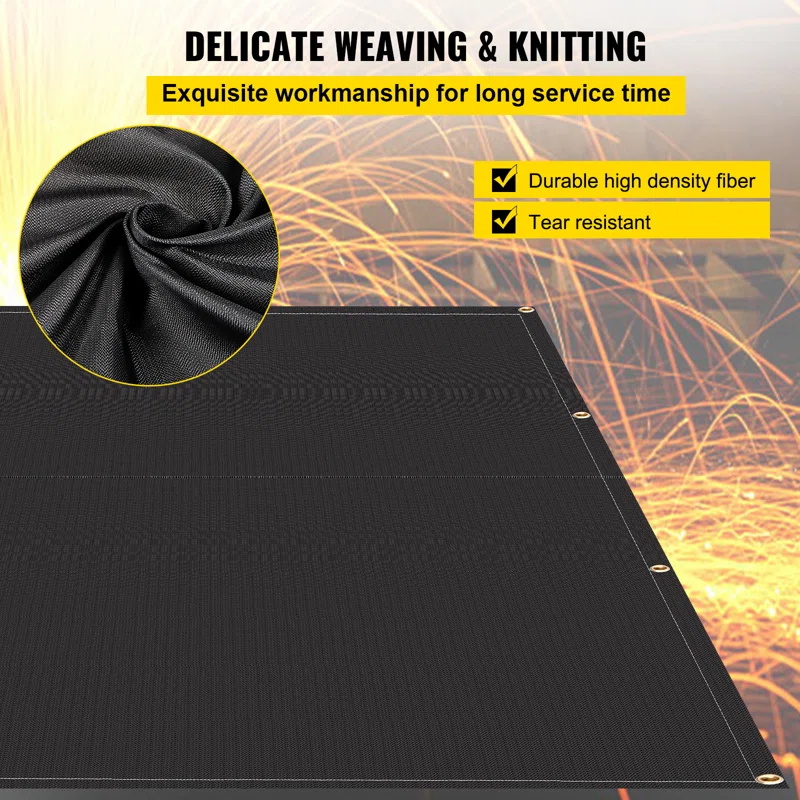

Flexible blanket fire protection refers to lightweight, heat-resistant fabrics designed to smother fires or shield objects from flames. Unlike rigid fireproof materials, these blankets conform to irregular shapes, making them ideal for wrapping valves, pipes, or electrical components. They typically combine fiberglass, silica, and ceramic fibers to withstand temperatures exceeding 1000°C.

Key Advantages Over Traditional Methods

When comparing flexible blanket fire protection to spray coatings or cementitious materials, three benefits stand out:

- Portability:Roll up and deploy where needed without permanent installation

- Reusability:Most quality blankets survive multiple fire events

- Precision protection:Wrap specific assets without covering entire structures

Industrial Applications You Should Know

Flexible blanket fire protection serves critical roles across industries:

Oil & Gas:Contain flare stack heat radiation and protect wellhead equipment. The blankets prevent ignition of nearby hydrocarbons during maintenance.

Power Plants:Wrap steam turbines and boilers to limit fire spread. Some utilities keep blankets near transformers for rapid response to electrical fires.

Manufacturing:Shield robotic arms in automotive plants from welding sparks. Food processing facilities use them to protect deep fryer areas.

Selection Criteria for Optimal Performance

Choosing the right flexible blanket fire protection involves four factors:

- Temperature rating:Match to your specific hazard (typically 500°C-1600°C)

- Chemical resistance:Verify compatibility with oils, acids, or solvents present

- Flexibility needs:Some designs accommodate frequent movement better

- Attachment method:Straps, hooks, or adhesive backing affect installation

Proper Maintenance Ensures Reliability

Your flexible blanket fire protection system requires regular inspection:

- Check for tears or thinning areas every 6 months

- Test attachment hardware functionality annually

- Replace if the blanket shows discoloration from heat exposure

- Store in accessible, dry locations away from chemical vapors

Installation Best Practices

Maximize your flexible blanket fire protection effectiveness with proper installation:

Full coverage:Overlap edges by at least 10cm to prevent flame penetration. Use high-temperature sealant at seams when needed.

Secure fastening:Stainless steel straps withstand heat better than plastic ties. Avoid over-tightening to prevent fiber damage.

Access considerations:Position blankets to allow routine equipment maintenance without removal.

Emergency Response Applications

Beyond preventive use, flexible blanket fire protection serves in emergencies:

Personnel protection:Workers can use smaller blankets as heat shields during evacuation.

Spill containment:Specialized versions absorb flammable liquids while suppressing vapors.

Equipment salvage:Quickly wrap servers or control panels to limit fire damage before sprinklers activate.

Cost-Benefit Analysis

While flexible blanket fire protection carries higher upfront costs than some alternatives, consider:

- Reduced downtime from targeted protection

- Lower installation labor versus sprayed materials

- Potential insurance premium reductions

- Extended equipment lifespan through heat management

Future Innovations in Fire Blanket Technology

Emerging flexible blanket fire protection developments include:

Smart sensors:Integrated temperature monitors that alert when thresholds are exceeded.

Self-sealing designs:Materials that expand to seal gaps when heated.

Eco-friendly formulations:Bio-based refractory fibers with equal performance.

Flexible blanket fire protection offers versatile, cost-effective solutions for modern fire safety challenges. By understanding proper selection, installation, and maintenance, you can significantly enhance your facility's protection against thermal hazards.