Ceramic Fiber Insulation Baffle Fire Blanket: Ultimate Heat Protection Solution

Ceramic fiber insulation baffle fire blankets provide superior thermal protection in high-temperature environments. This guide explains their composition, applications, benefits, and proper usage to help you select the right fire protection solution.

What Is a Ceramic Fiber Insulation Baffle Fire Blanket?

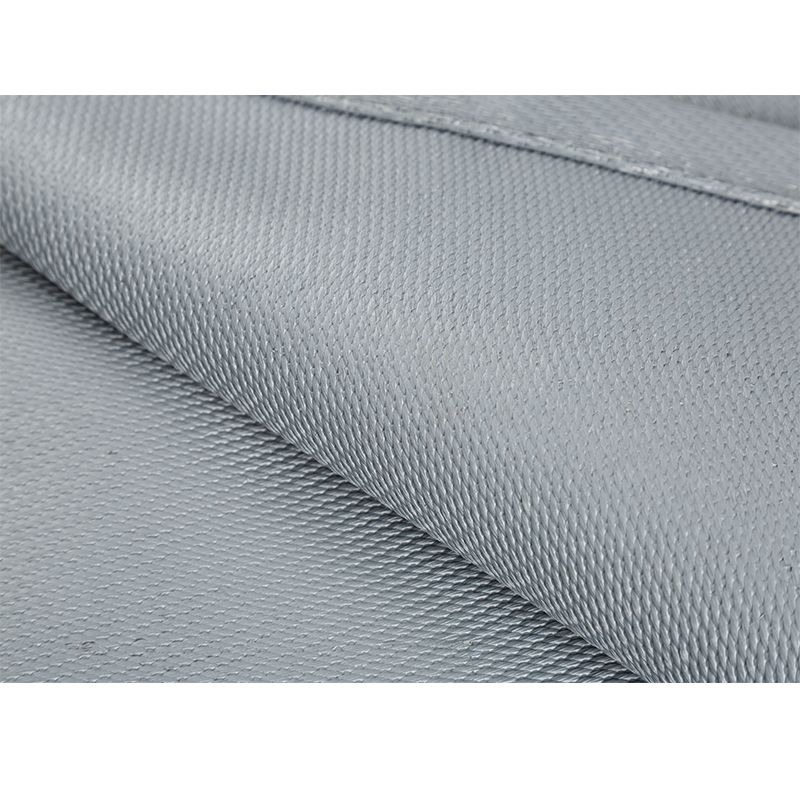

A ceramic fiber insulation baffle fire blanket is a specialized safety device made from high-temperature resistant ceramic fibers. These blankets are designed to withstand extreme heat (up to 2300°F/1260°C) while providing excellent insulation properties. The "baffle" refers to its ability to deflect and manage heat flow.

Key Features and Benefits

When you choose a ceramic fiber insulation baffle fire blanket, you get several advantages:

- Exceptional heat resistance:Protects against direct flame and radiant heat

- Low thermal conductivity:Minimizes heat transfer to protected surfaces

- Chemical stability:Resists most corrosive substances

- Lightweight:Easy to handle and install compared to metal alternatives

- Flexible:Can conform to various shapes and surfaces

Common Applications

You'll find ceramic fiber insulation baffle fire blankets used in multiple industries:

- Industrial furnaces:Protects equipment and personnel from extreme heat

- Power plants:Shields sensitive components in boilers and turbines

- Welding operations:Contains sparks and prevents fire spread

- Aerospace:Thermal protection in engine compartments

- Fire safety:Emergency protection for personnel evacuation

How to Choose the Right Blanket

When selecting your ceramic fiber insulation baffle fire blanket, consider these factors:

- Temperature rating:Match the blanket to your maximum operating temperature

- Thickness:Thicker blankets provide better insulation but may be less flexible

- Size:Ensure coverage for your specific application

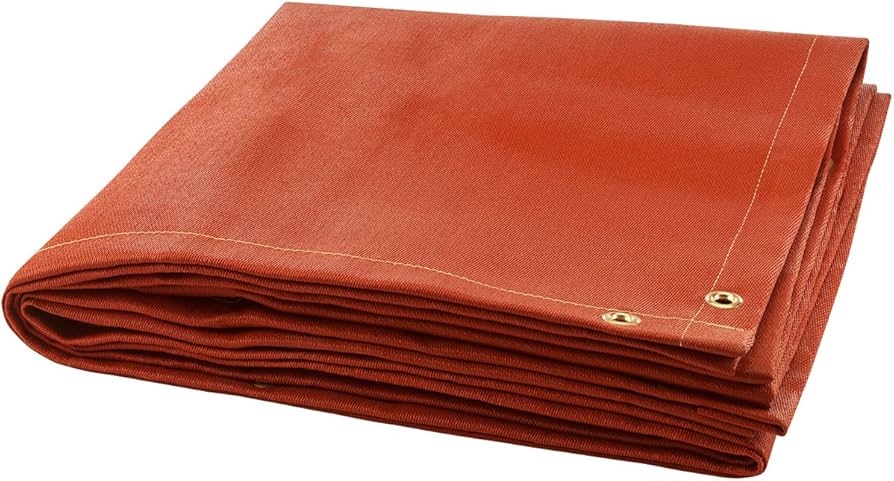

- Attachment method:Some include grommets or hooks for secure mounting

- Certifications:Look for relevant industry standards compliance

Proper Installation and Maintenance

To get the most from your ceramic fiber insulation baffle fire blanket:

- Install with proper overlap (minimum 2 inches) at seams

- Secure firmly to prevent movement or gaps

- Inspect regularly for tears or degradation

- Clean with compressed air - avoid water which can damage fibers

- Replace when you notice significant wear or reduced performance

Safety Considerations

While ceramic fiber insulation baffle fire blankets are safe when installed properly, you should:

- Wear gloves during handling to prevent fiber irritation

- Use in well-ventilated areas during installation

- Follow manufacturer's guidelines for specific applications

- Keep away from sharp edges that could damage the material

Comparing to Alternative Materials

Ceramic fiber insulation baffle fire blankets outperform many alternatives:

| Material | Max Temperature | Weight | Flexibility |

|---|---|---|---|

| Ceramic Fiber | 2300°F (1260°C) | Light | High |

| Fiberglass | 1200°F (650°C) | Light | Medium |

| Metal | Varies | Heavy | Low |

Conclusion

A ceramic fiber insulation baffle fire blanket provides superior thermal protection for demanding industrial applications. By understanding its properties and proper usage, you can significantly improve safety and efficiency in high-temperature environments. Always consult with manufacturers for specific application recommendations.