Silicone Coated Fiberglass Welding Blanket: Ultimate Heat Protection Solution

This guide explains how silicone coated fiberglass welding blankets protect against sparks, slag, and heat up to 2000°F. You'll learn their benefits, proper usage, and how they outperform regular welding blankets.

What Is a Silicone Coated Fiberglass Welding Blanket?

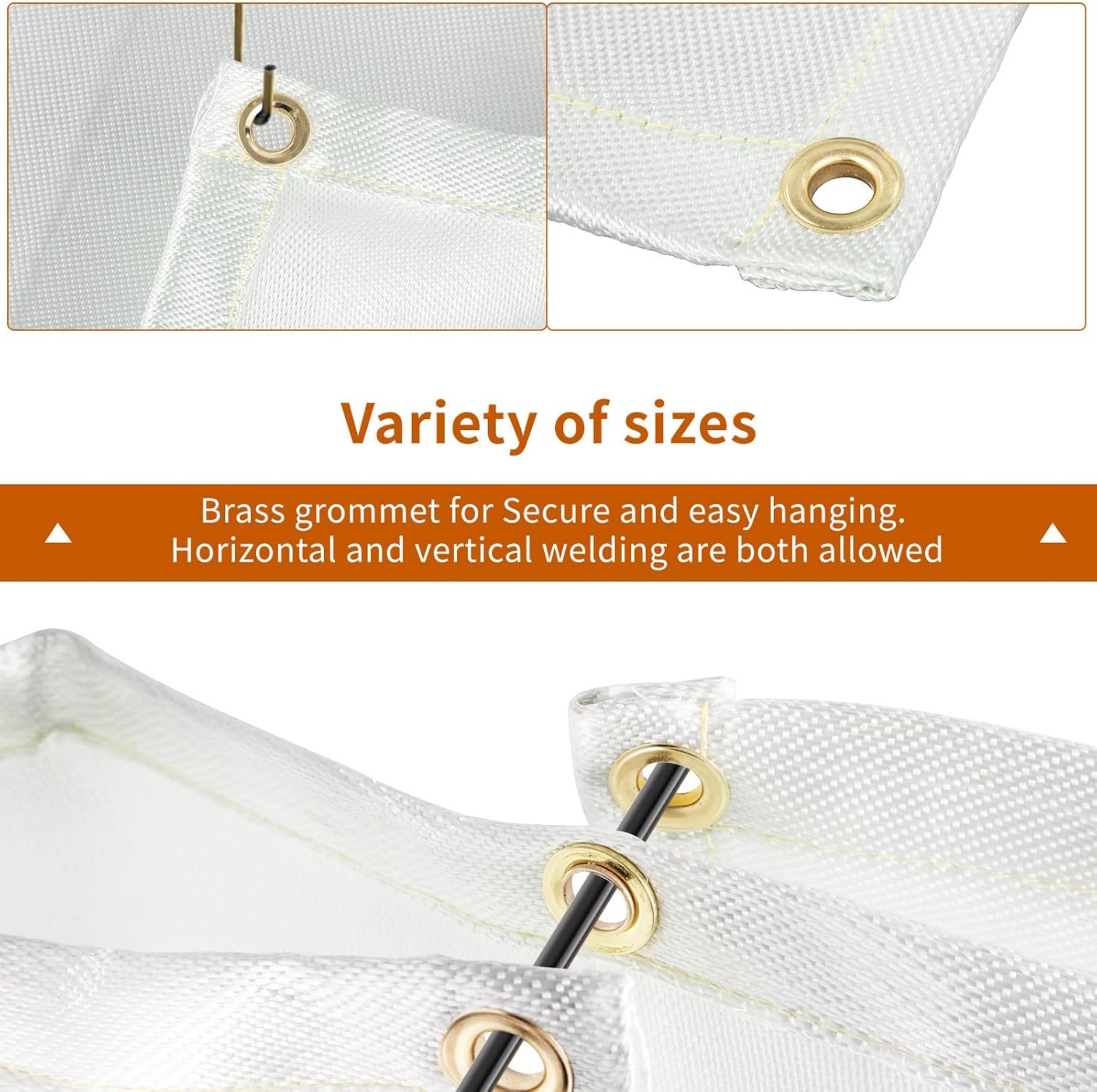

A silicone coated fiberglass welding blanket is a specialized protective cover made from woven fiberglass fabric with a silicone rubber coating. The silicone coating makes the blanket more durable, flexible, and resistant to extreme temperatures compared to uncoated versions.

These blankets typically withstand continuous temperatures up to 1000°F (538°C) and can handle brief exposures up to 2000°F (1093°C). The silicone coating prevents fiberglass strands from breaking loose while adding water and chemical resistance.

Key Benefits for Welders and Metalworkers

When you use a silicone coated fiberglass welding blanket, you get several advantages:

- Superior heat resistance:Protects nearby surfaces from welding sparks better than standard blankets

- Longer lifespan:Silicone coating prevents fiberglass degradation from UV exposure and repeated folding

- Easy cleanup:Molten metal and slag don't stick to the silicone surface

- Flexibility:Remains pliable in cold temperatures when uncoated blankets become stiff

- Non-conductive:Won't create electrical hazards in your workspace

Proper Usage Tips

To get maximum protection from your silicone coated fiberglass welding blanket:

- Always overlap multiple blankets by at least 6 inches when covering large areas

- Secure edges with non-flammable weights or clamps to prevent lifting

- Inspect for damage before each use - replace if coating is cracked or fiberglass shows through

- Store folded or rolled in a dry location away from direct sunlight

- Clean with compressed air or a soft brush - avoid harsh chemicals that could degrade silicone

Comparing to Other Welding Blanket Types

While uncoated fiberglass blankets cost less initially, silicone coated versions provide better long-term value:

| Feature | Silicone Coated | Uncoated Fiberglass |

|---|---|---|

| Lifespan | 3-5 years with proper care | 1-2 years typically |

| Temperature Resistance | Up to 2000°F intermittent | Up to 1500°F intermittent |

| Flexibility in Cold | Excellent | Becomes stiff |

Common Applications Beyond Welding

While designed for welding, these versatile blankets also work well for:

- Foundry work and metal casting protection

- Fireplace and wood stove heat shields

- Automotive exhaust system repairs

- Industrial furnace maintenance

- Hot work permits in construction

Safety Considerations

Though highly protective, remember:

- Never use as personal protective equipment (PPE) - always wear proper welding gear

- Avoid contact with sharp edges that could cut through the material

- Keep away from open flames as silicone can eventually burn at extreme temperatures

- Allow to cool completely before handling or storing

Choosing the Right Size and Thickness

Select your silicone coated fiberglass welding blanket based on:

- Work area size:Common sizes range from 3'x3' to 10'x10'

- Heat intensity:Thicker blankets (1/8"+) for prolonged high-heat applications

- Mobility needs:Lighter weights for frequent repositioning

For most welding shops, a medium-weight 6'x6' blanket provides the best balance of coverage and maneuverability.

Maintenance for Longevity

Proper care extends your blanket's useful life:

- Shake out debris after each use

- Spot clean with mild soap and water if needed

- Store flat or loosely rolled to prevent creasing

- Rotate between multiple blankets if used daily

With proper care, a quality silicone coated fiberglass welding blanket will protect your workspace for years of heavy use.