Fire Resistant Fabric Welding Blanket: Essential Protection for Safe Welding

Fire resistant fabric welding blankets protect against sparks, slag, and heat during welding. These specialized safety tools prevent fires and protect surrounding areas. This guide explains their features, benefits, and proper use.

What Is a Fire Resistant Fabric Welding Blanket?

A fire resistant fabric welding blanket is a safety device made from specially treated materials that resist ignition and extreme heat. When you're welding, cutting, or grinding, these blankets shield nearby flammable objects from sparks and molten metal.

Unlike regular tarps or fabrics, welding blankets won't catch fire when exposed to welding sparks or hot metal fragments. They're designed to withstand temperatures up to 1,800°F (982°C) depending on the material composition.

Key Materials Used in Welding Blankets

Manufacturers use several fire resistant materials for welding blankets:

- Fiberglass:The most common material, offering good heat resistance up to 1,000°F (538°C)

- Silica:Provides higher temperature resistance up to 1,800°F (982°C)

- Carbon fiber:Used in specialized applications requiring extreme heat protection

- Ceramic fiber:For ultra-high temperature environments above 2,000°F (1,093°C)

Many welding blankets combine these materials with protective coatings to enhance durability and fire resistance. The fire resistant fabric welding blanket you choose should match your specific welding temperature requirements.

Why You Need a Fire Resistant Welding Blanket

Welding generates extreme heat and sparks that can travel up to 35 feet (10.7 meters). Without proper protection, these can ignite nearby materials. A quality fire resistant fabric welding blanket provides multiple safety benefits:

- Prevents workplace fires by containing sparks and molten metal

- Protects floors, walls, and equipment from heat damage

- Creates a safe work area when welding in confined spaces

- Reduces insurance risks by demonstrating safety compliance

- Lasts longer than makeshift solutions like wet cardboard

Choosing the Right Welding Blanket

Selecting the appropriate fire resistant fabric welding blanket depends on several factors:

Temperature Rating

Match the blanket's maximum temperature rating to your welding process. MIG and TIG welding typically require blankets rated for at least 1,000°F (538°C), while plasma cutting may need 1,800°F (982°C) protection.

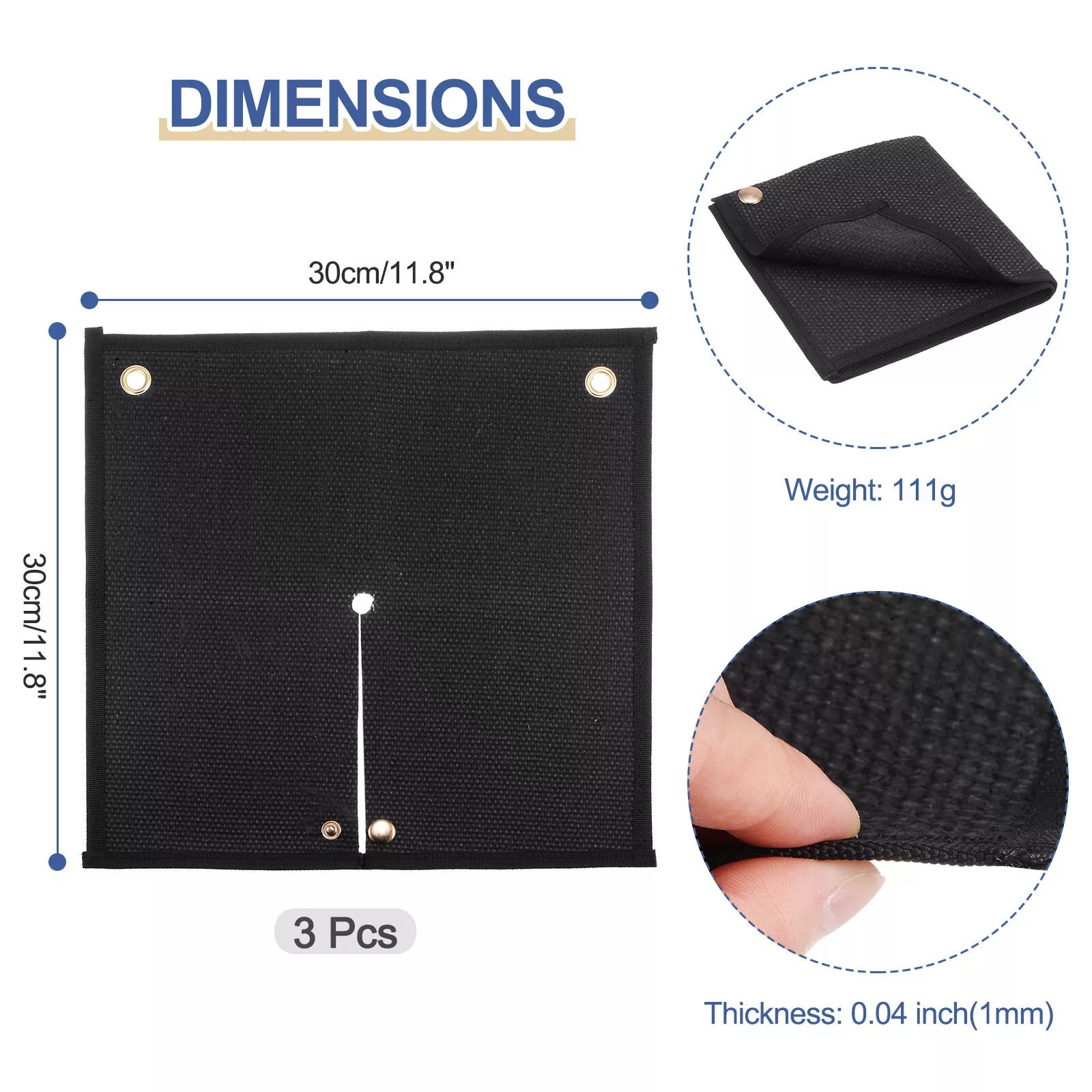

Size Requirements

Measure your work area and choose a blanket that provides adequate coverage with some overlap. Common sizes range from 3'x3' (0.9x0.9m) for small jobs to 12'x12' (3.7x3.7m) for large projects.

Material Thickness

Thicker blankets (1/8" or 3mm+) offer better protection for heavy-duty welding but may be less flexible. Thinner options work for light-duty applications where maneuverability matters.

Safety Certifications

Look for blankets meeting recognized standards like NFPA 701 (fire resistance) or OSHA 1910.252 (welding safety). Reputable manufacturers provide test data and certifications.

Proper Use and Maintenance

To maximize the effectiveness and lifespan of your fire resistant fabric welding blanket:

- Inspect before each use for holes, tears, or excessive wear

- Position the blanket to fully cover vulnerable areas

- Secure edges with weights or clamps to prevent shifting

- Allow the blanket to cool completely before moving or folding

- Store in a dry, clean area away from direct sunlight

- Clean with compressed air or a soft brush - avoid water unless specified

- Replace when you notice significant wear or reduced fire resistance

Common Applications Beyond Welding

While designed for welding, these versatile blankets serve multiple industrial purposes:

- Hot work area containment in construction

- Fireproof curtains in manufacturing facilities

- Thermal insulation for pipes and equipment

- Spark protection during grinding operations

- Emergency fire suppression in vehicle maintenance

Safety Considerations

Remember that even the best fire resistant fabric welding blanket has limits:

- Never use a welding blanket as personal protective equipment (PPE)

- Avoid direct contact with molten metal - blankets resist but don't block all heat transfer

- Don't use damaged blankets - small holes can compromise protection

- Keep fire extinguishers accessible when welding, regardless of blanket use

- Train all workers on proper blanket deployment and limitations

Conclusion

A fire resistant fabric welding blanket is an essential safety tool for any welding operation. By understanding the different types, proper selection criteria, and correct usage techniques, you can significantly reduce fire risks in your workplace. Invest in quality blankets that meet your specific needs and maintain them properly for long-lasting protection.