Welding Fire Blankets: Essential Safety Gear for Spark Protection

Summary:Fire blankets for welding protect against sparks and flames. Made from flame-resistant materials, they shield surfaces and prevent fire spread. This guide covers types, uses, and selection tips for welding safety.

Why You Need Fire Blankets for Welding

When you weld, sparks and molten metal can travel up to 35 feet. These hot particles ignite flammable materials easily. Fire blankets create a protective barrier between your welding area and combustible surfaces. Unlike regular blankets, welding fire blankets withstand temperatures up to 1,800°F (982°C).

How Welding Fire Blankets Work

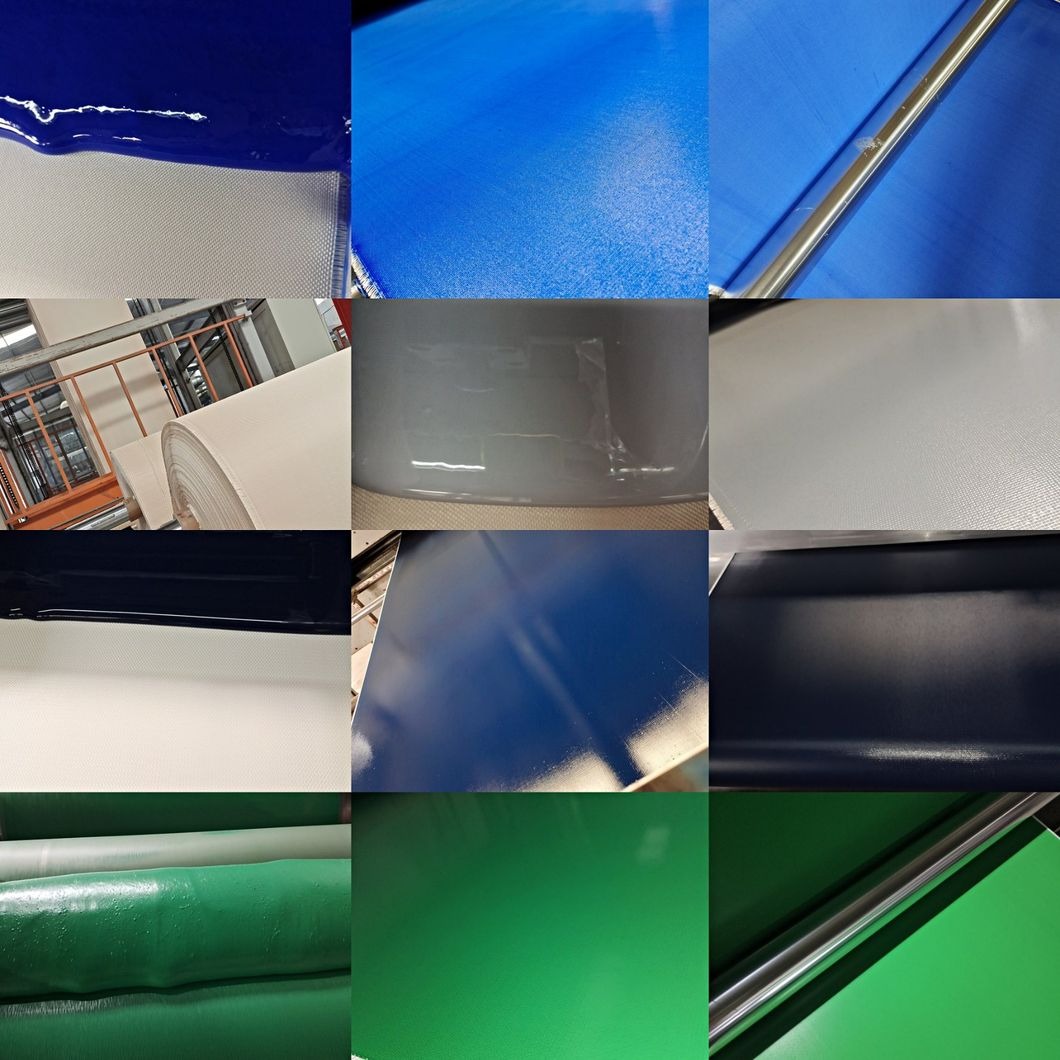

Quality fire blankets for welding use fiberglass or silica fabric with special coatings. The material doesn't burn or conduct heat quickly. When sparks land on the blanket, they cool immediately without igniting. Some advanced models include aluminum layers for extra reflectivity.

Key Features to Look For

- Material:Fiberglass is standard; silica offers higher heat resistance

- Size:4'x6' covers most small jobs; 6'x8' for larger areas

- Thickness:0.04" minimum for welding applications

- Edge treatment:Reinforced stitching prevents fraying

- Portability:Look for foldable designs with storage bags

Proper Use of Welding Fire Blankets

Always inspect your fire blanket before use. Hang it vertically to protect walls or lay it flat on floors. Overlap multiple blankets by 6 inches for complete coverage. Keep the blanket at least 3 feet from your actual welding spot - close enough for protection but not so close it melts.

Maintenance and Care

Shake out debris after each use. Wash only when necessary using mild detergent - never bleach. Air dry completely before storing. Replace blankets with holes larger than 1 inch or stiff areas that won't fold properly. Most welding blankets last 1-3 years with regular use.

Beyond Welding: Other Uses

Your fire blanket serves multiple safety purposes:

- Grinding operations

- Hot work in confined spaces

- Emergency fire suppression

- Protecting sensitive equipment near work areas

Common Mistakes to Avoid

Don't use regular tarps as substitutes - they melt instantly. Never leave blankets touching red-hot metal. Avoid folding dirty blankets - embedded metal shavings cause premature wear. Remember that fire blankets supplement - but don't replace - proper PPE like gloves and face shields.

Choosing the Right Blanket for Your Work

Match your blanket to your welding type:

| Welding Process | Recommended Blanket |

|---|---|

| MIG/TIG | Standard fiberglass (1,000°F rating) |

| Stick welding | Heavy-duty fiberglass (1,500°F+) |

| Plasma cutting | Silica-aluminum composite |

Where to Buy Quality Fire Blankets

Purchase from welding supply stores or reputable online retailers. Look for UL certification or EN 1869 compliance. Popular brands include Tillman, Black Stallion, and Lincoln Electric. Expect to pay $30-$150 depending on size and quality.

Final Safety Reminders

Always keep a fire extinguisher nearby when welding. Train all workers in blanket deployment. Store blankets in dry, accessible locations. Remember that proper use of fire blankets for welding prevents most workshop fires before they start.