Cloth Welding Blanket Guide: Safety Tips & Material Selection for Welders

Summary:Cloth welding blankets protect against sparks and heat during welding. This guide explains their materials, proper usage, maintenance, and how to choose the right one for your projects. Learn essential safety practices with welding blankets.

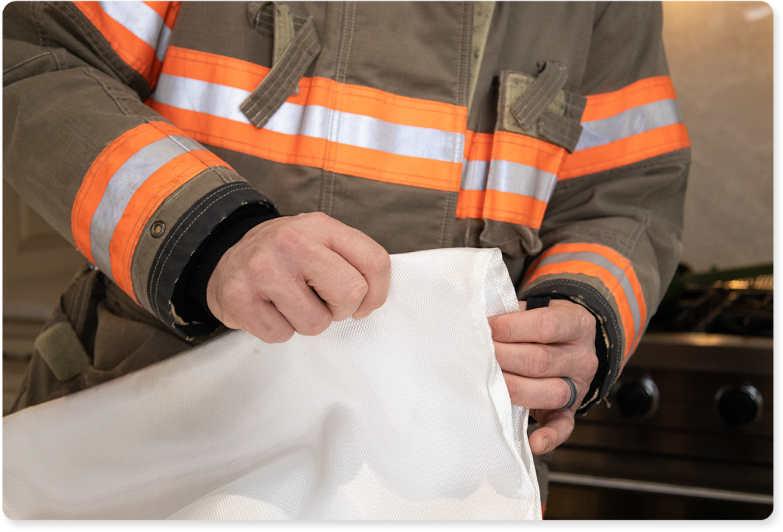

What Is a Cloth Welding Blanket?

A cloth welding blanket is a protective covering made from fire-resistant materials. You use it to shield nearby surfaces from sparks, spatter, and heat during welding operations. Unlike plastic or fiberglass alternatives, cloth blankets offer better flexibility and durability for various work environments.

Key Materials in Quality Welding Blankets

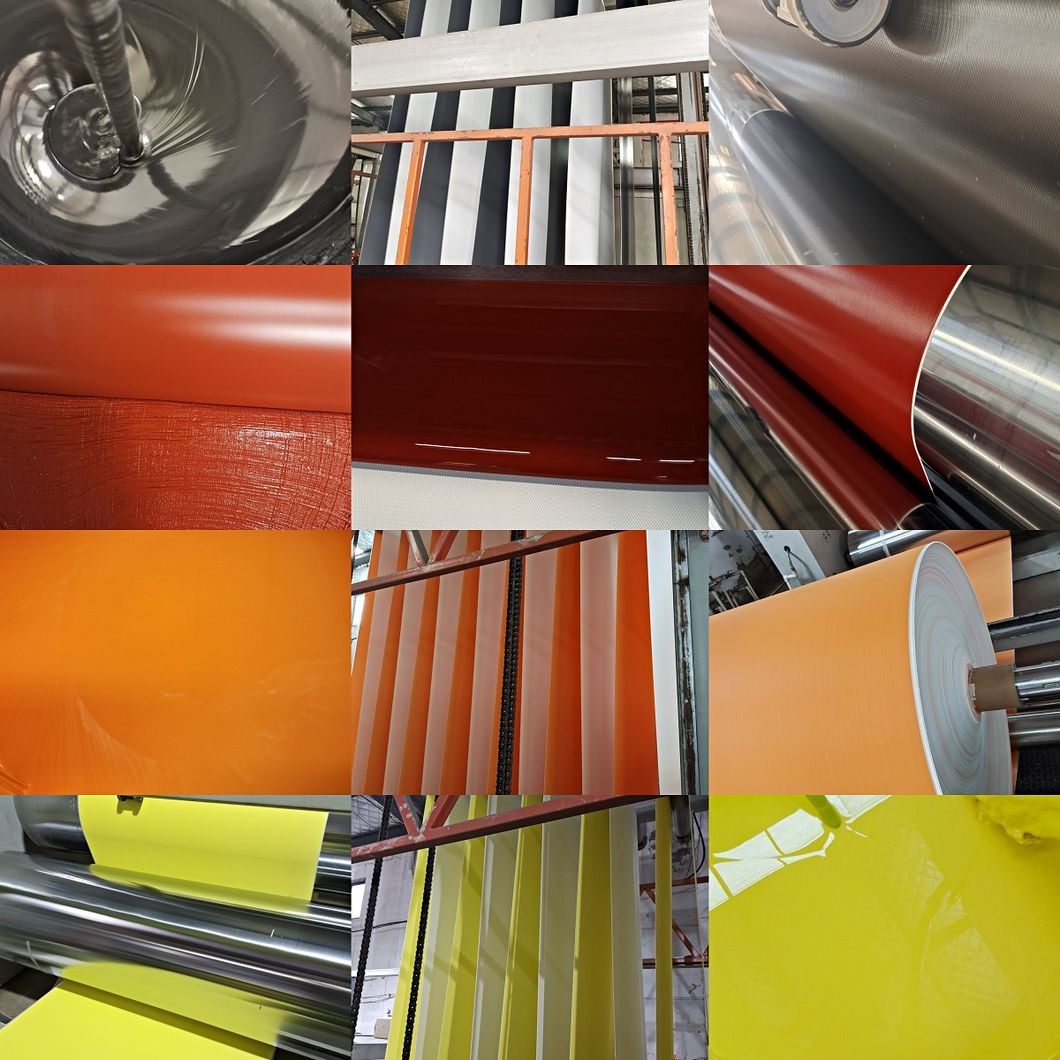

When selecting your cloth welding blanket, pay attention to these materials:

- Fiberglass:Most common base material with excellent heat resistance

- Silicone-coated fabrics:Provide additional protection against molten metal

- Carbon fiber:For high-temperature applications above 2000°F

- Vermiculite-coated cloth:Offers superior spark resistance

How to Use Your Welding Blanket Safely

Follow these steps for proper cloth welding blanket usage:

- Inspect your blanket for tears or damage before each use

- Cover all flammable surfaces within 35 feet of your work area

- Secure the blanket with non-flammable weights or clamps

- Overlap multiple blankets by at least 6 inches when covering large areas

- Never use wet blankets - moisture reduces heat resistance

Choosing the Right Blanket for Your Projects

Consider these factors when buying a cloth welding blanket:

| Project Type | Recommended Blanket |

|---|---|

| Light-duty MIG welding | Fiberglass with silicone coating (1000°F rating) |

| Heavy industrial welding | Carbon fiber reinforced (2000°F+ rating) |

| Outdoor welding | UV-resistant treated fabric |

Maintenance Tips for Longevity

Extend your cloth welding blanket's lifespan with proper care:

- Shake off debris after each use - never brush aggressively

- Store folded or rolled in a dry, clean area

- Wash only when necessary using mild detergent (check manufacturer instructions)

- Inspect stitching regularly - repairs small tears immediately

- Replace when the material becomes stiff or shows significant wear

Safety Precautions You Shouldn't Ignore

While cloth welding blankets provide excellent protection, remember:

- They don't replace proper PPE (always wear gloves, helmet, etc.)

- Never use them as personal protection - only for surface coverage

- Avoid direct contact with open flames (blankets resist heat, not continuous fire)

- Keep chemical cleaners away - some solvents degrade fire-resistant treatments

Common Mistakes to Avoid

Watch out for these frequent errors with cloth welding blankets:

- Using undersized blankets that leave areas unprotected

- Folding too tightly - causes premature material breakdown

- Assuming all "fire-resistant" labels mean equal protection

- Neglecting to check temperature ratings for specific welding processes

- Storing near sharp objects that could puncture the material

When to Replace Your Welding Blanket

Recognize these signs that your cloth welding blanket needs replacement:

- Visible holes or frayed edges larger than 1 inch

- Stiffness that prevents proper draping over surfaces

- Discoloration indicating chemical degradation

- Loss of flexibility in folded areas

- Reduced effectiveness in spark containment

By understanding these aspects of cloth welding blankets, you'll make informed decisions about selection, usage, and maintenance. Proper care ensures your blanket provides reliable protection throughout its service life, keeping your workspace safe from welding hazards.