How a Welding Blanket for Suppressor Cover Protects Your Gear

Summary:A welding blanket for suppressor cover shields your firearm from heat damage during rapid fire. This heat-resistant fabric wrap prevents burns and maintains accuracy by managing suppressor temperatures effectively.

Why You Need a Welding Blanket for Your Suppressor

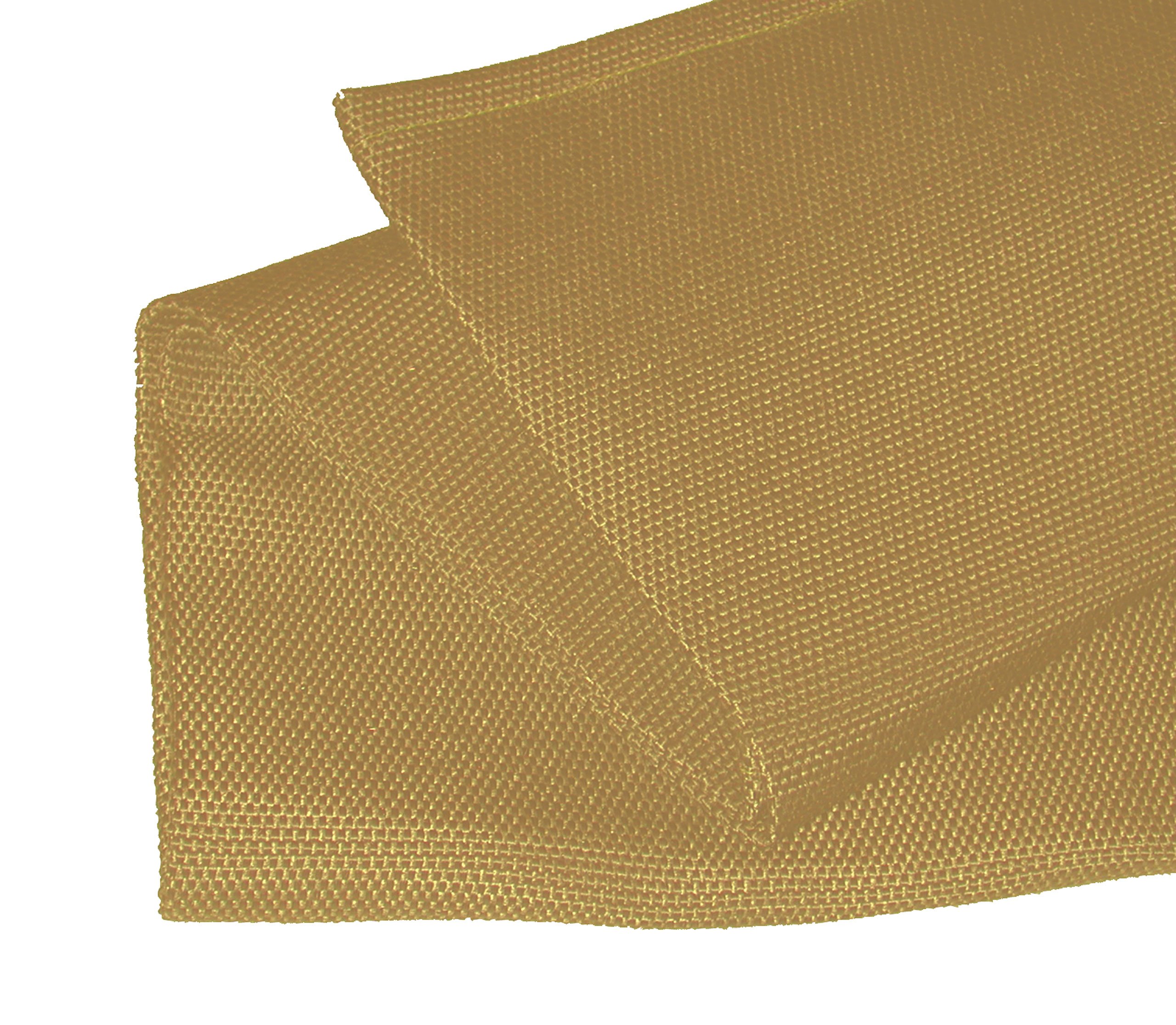

When you fire multiple rounds quickly, your suppressor gets extremely hot. Standard covers might not handle this heat, but a welding blanket material does. These specialized wraps use the same heat-resistant fibers found in industrial welding protection, adapted for firearm use.

Key Benefits of Using Welding Blanket Material

1. Extreme Heat Resistance:Withstands temperatures up to 1,800°F (982°C), far beyond what most suppressor covers can handle.

2. Protection During Transport:Keeps your gear bag safe when storing a hot suppressor after shooting sessions.

3. Prevents Heat Mirage:The thick fabric reduces visible heat waves that distort your sight picture during rapid fire.

4. Durability:Resistant to sparks, molten metal splatter, and abrasion - perfect for tactical environments.

How to Choose the Right Welding Blanket Cover

Not all welding blanket materials work equally well for suppressors. Look for these features:

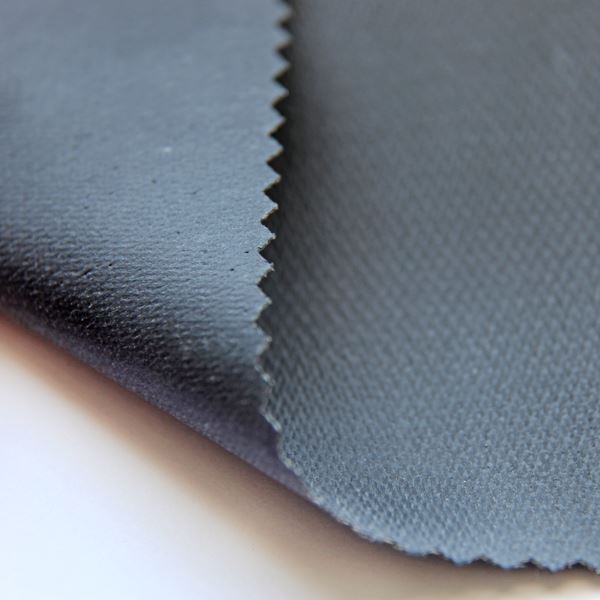

- Fiberglass or silica fabric construction (avoid cheap synthetic blends)

- Double-stitched seams with high-temp thread

- Adjustable straps or bungee closures for secure fit

- Proper sizing - should cover entire suppressor with some overlap

- Non-reflective outer surface for tactical applications

Proper Use and Maintenance

To get the most from your welding blanket suppressor cover:

Installation:Slide it over your cool suppressor before shooting begins. Ensure it's snug but not restricting gas flow.

During Use:The cover will darken with heat exposure - this is normal. Avoid touching it directly after firing.

Cleaning:Shake out carbon buildup regularly. Hand wash with mild detergent if heavily soiled, then air dry completely.

Replacement Signs:Look for frayed edges, thinning fabric, or loss of flexibility - typically after 500-700 rounds.

DIY vs. Commercial Options

While you can make a basic cover from raw welding blanket material, commercial versions offer advantages:

| Feature | DIY | Commercial |

|---|---|---|

| Precision Fit | ✓ | ✓✓✓ |

| Secure Attachment | ✓ | ✓✓✓ |

| Reflective Layer | ✓✓ | ✓✓✓ |

| Warranty | ✗ | ✓✓✓ |

Common Questions Answered

Q: Will it affect suppressor performance?A: No quality cover should impact sound reduction or gas flow when properly fitted.

Q: Can I use it on other hot gun parts?A: Yes, many shooters use spare covers on barrels or gas blocks during extended sessions.

Q: How does it compare to silicone covers?A: Welding blanket material handles higher temperatures but may be slightly heavier.

Final Recommendations

For serious shooters who push their gear hard, a welding blanket suppressor cover provides unmatched protection. Look for military-grade options if you need maximum durability. Remember that proper fit matters as much as material quality - test the cover with your specific suppressor model before field use.