High-Temp Silicone Coated Fiberglass Welding Blanket Roll Safety Guide

Summary:Silicone coated fiberglass welding blanket rolls provide heat-resistant protection for welding, foundries, and industrial applications. This guide explains their features, benefits, proper usage, and safety considerations.

What Is a Silicone Coated Fiberglass Welding Blanket Roll?

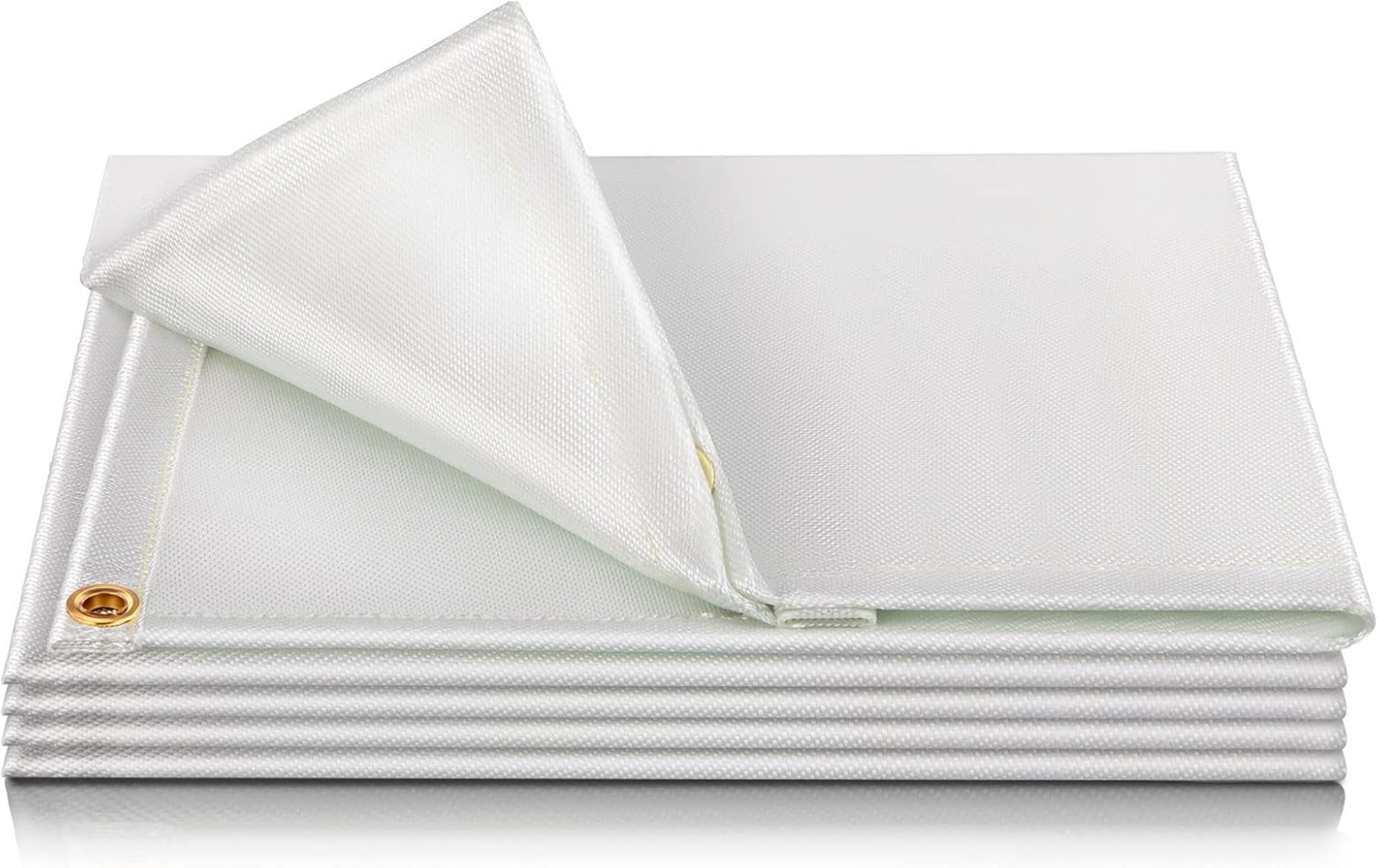

When you work with high temperatures, you need reliable protection. A silicone coated fiberglass welding blanket roll is a flexible, heat-resistant fabric made from woven fiberglass with a silicone rubber coating. The rolls come in various widths (typically 48" to 72") and lengths (10-50 feet), allowing you to cut custom-sized blankets.

Key Benefits for Industrial Applications

These welding blanket rolls offer three main advantages:

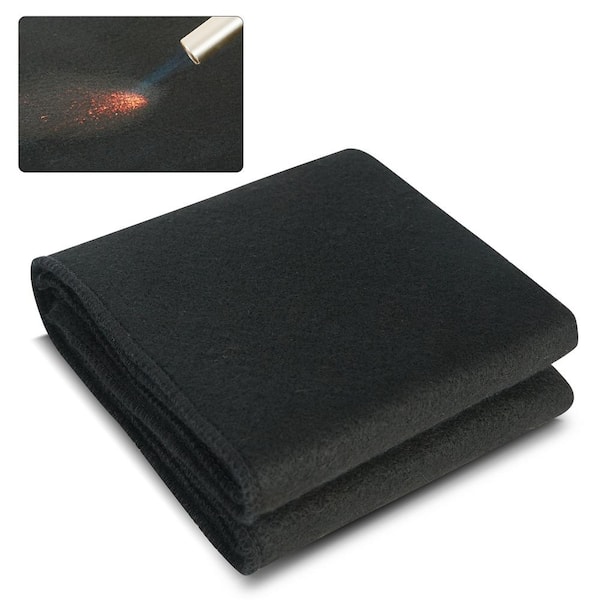

- Heat resistance:Withstands continuous exposure to 500°F (260°C) and intermittent peaks up to 1000°F (538°C)

- Durability:The silicone coating prevents fiberglass fraying while maintaining flexibility

- Multi-purpose protection:Use them as welding curtains, furnace insulation, or spark barriers

How to Choose the Right Blanket Roll

Consider these factors when selecting your silicone coated fiberglass welding blanket roll:

- Thickness:Standard options range from 1/16" to 1/8" - thicker materials provide better insulation

- Color coding:Available in natural (beige) or safety orange for high-visibility areas

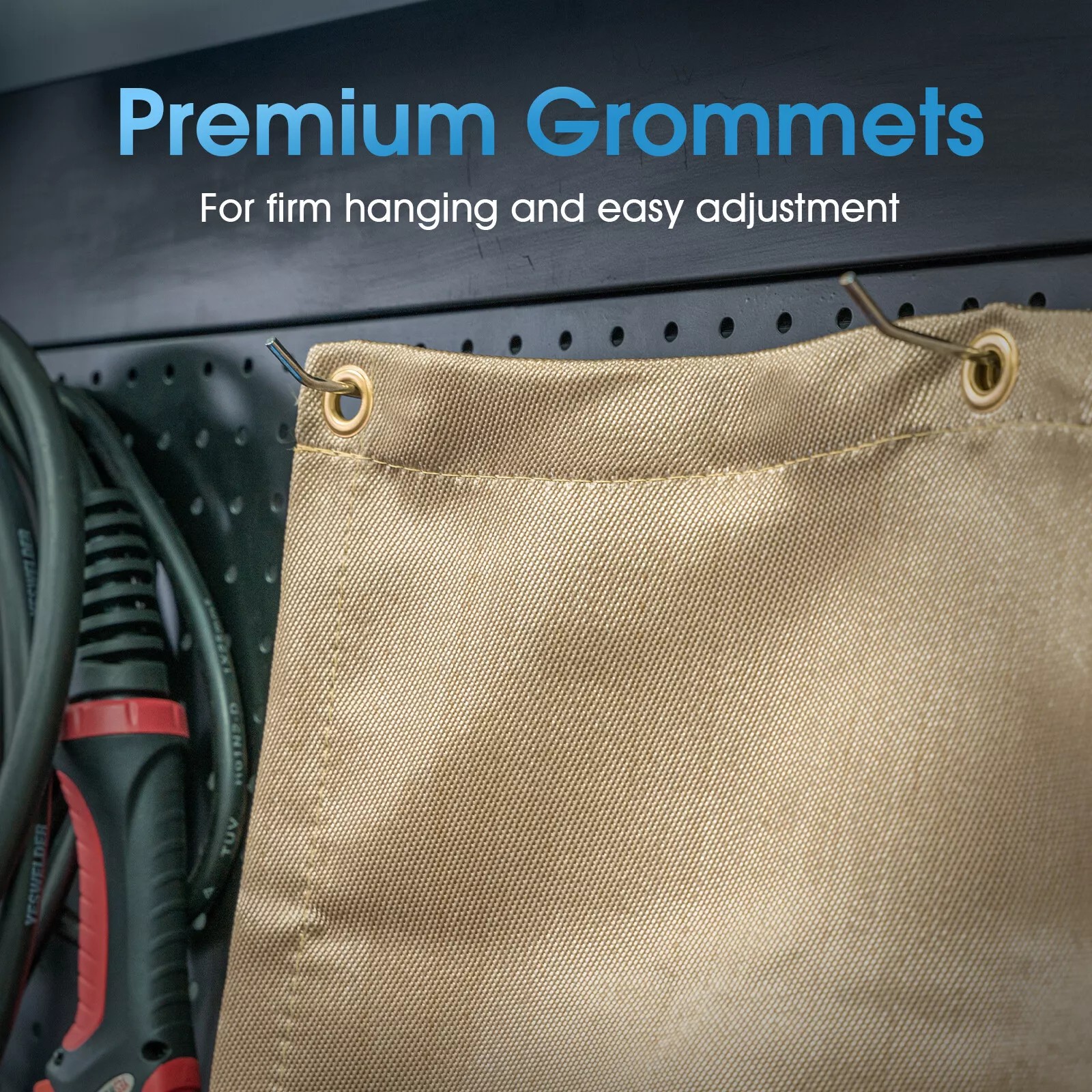

- Reinforcement:Some rolls include grommets or reinforced edges for hanging applications

Proper Installation and Usage Tips

To maximize safety and performance:

- Overlap sections by at least 6 inches when covering large areas

- Secure edges with high-temperature tape or stainless steel clips

- Keep at least 12" clearance from open flames despite the material's fire resistance

- Inspect regularly for tears or excessive wear - replace when coating wears through

Maintenance and Safety Precautions

While silicone coated fiberglass welding blanket rolls are durable, proper care extends their lifespan:

- Clean with compressed air or a soft brush - avoid water that could trap in fibers

- Store rolled up in a dry area when not in use

- Always wear gloves when handling to prevent fiberglass irritation

- Never use damaged blankets - exposed fiberglass can cause skin irritation

Common Applications Beyond Welding

These versatile rolls serve multiple industrial purposes:

- Foundry work: Protecting floors from molten metal splashes

- Automotive: Shielding paint booths from overspray

- Construction: Temporary heat barriers during hot work operations

- Manufacturing: Insulating pipes and equipment

Comparison to Alternative Materials

Silicone coated fiberglass welding blanket rolls outperform other options:

| Material | Max Temperature | Flexibility | Lifespan |

|---|---|---|---|

| Silicone Fiberglass | 1000°F | Excellent | 3-5 years |

| Leather | 400°F | Good | 1-2 years |

| Uncoated Fiberglass | 800°F | Fair | 1 year |

Where to Buy Quality Welding Blanket Rolls

Purchase from industrial safety suppliers who provide:

- Certifications (OSHA, ANSI compliance)

- Custom cutting services

- Technical specifications sheets

Remember that investing in a premium silicone coated fiberglass welding blanket roll pays off through longer service life and better protection.