Industrial Fire Retardant Blankets: Essential Safety Gear for Workplace Protection

Industrial fire retardant blankets are crucial safety tools that smother small fires and protect workers from heat and flames. This guide explains their materials, uses, maintenance, and selection criteria for optimal workplace safety.

What Are Industrial Fire Retardant Blankets?

Industrial fire retardant blankets are specially designed safety devices made from flame-resistant materials. Unlike regular blankets, they can withstand extreme temperatures up to 1000°F (538°C) or higher, depending on the material. You'll find them in workshops, factories, laboratories, and any workplace with fire risks.

Key Materials and How They Work

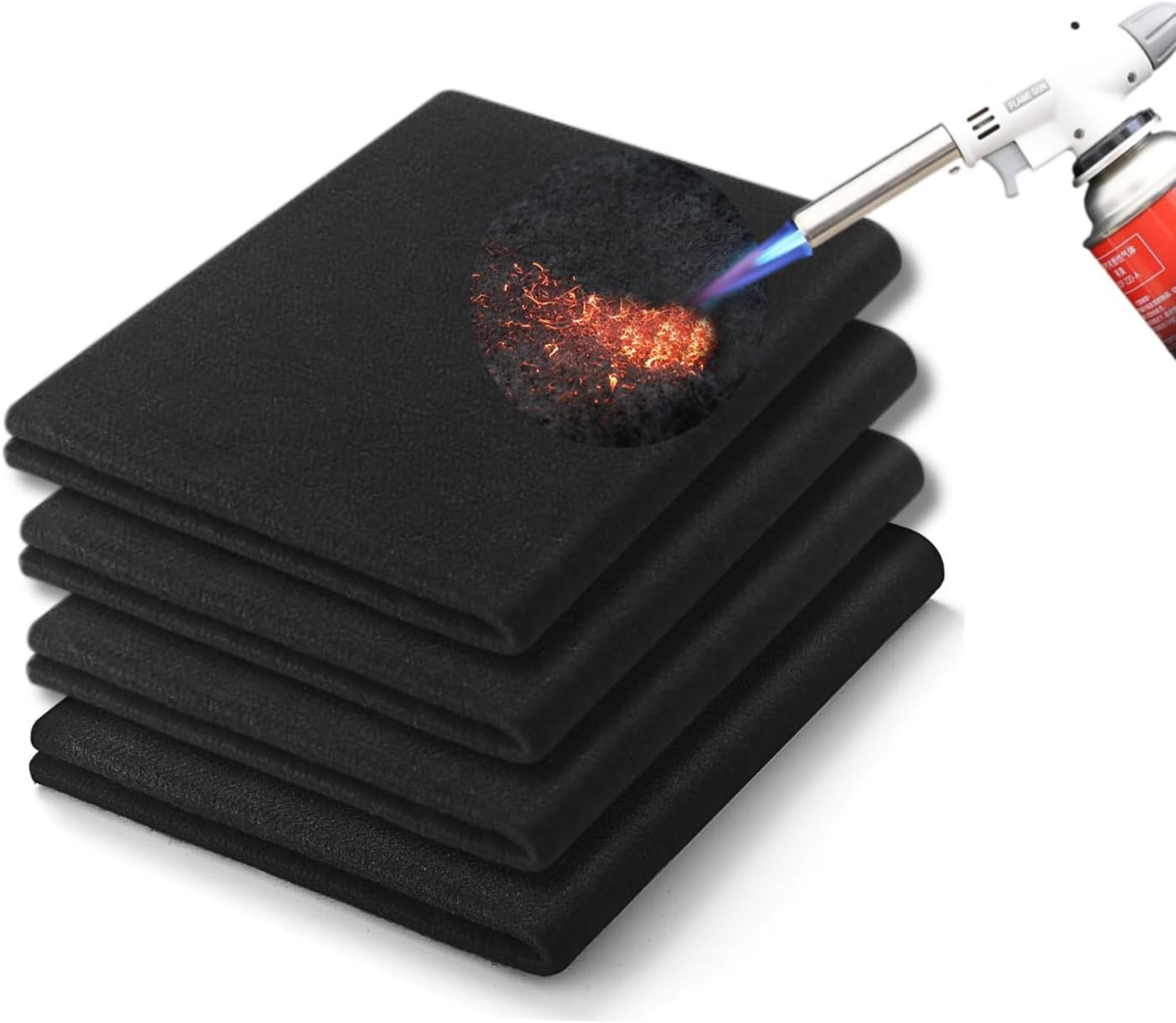

These blankets use advanced materials that resist ignition and prevent fire spread:

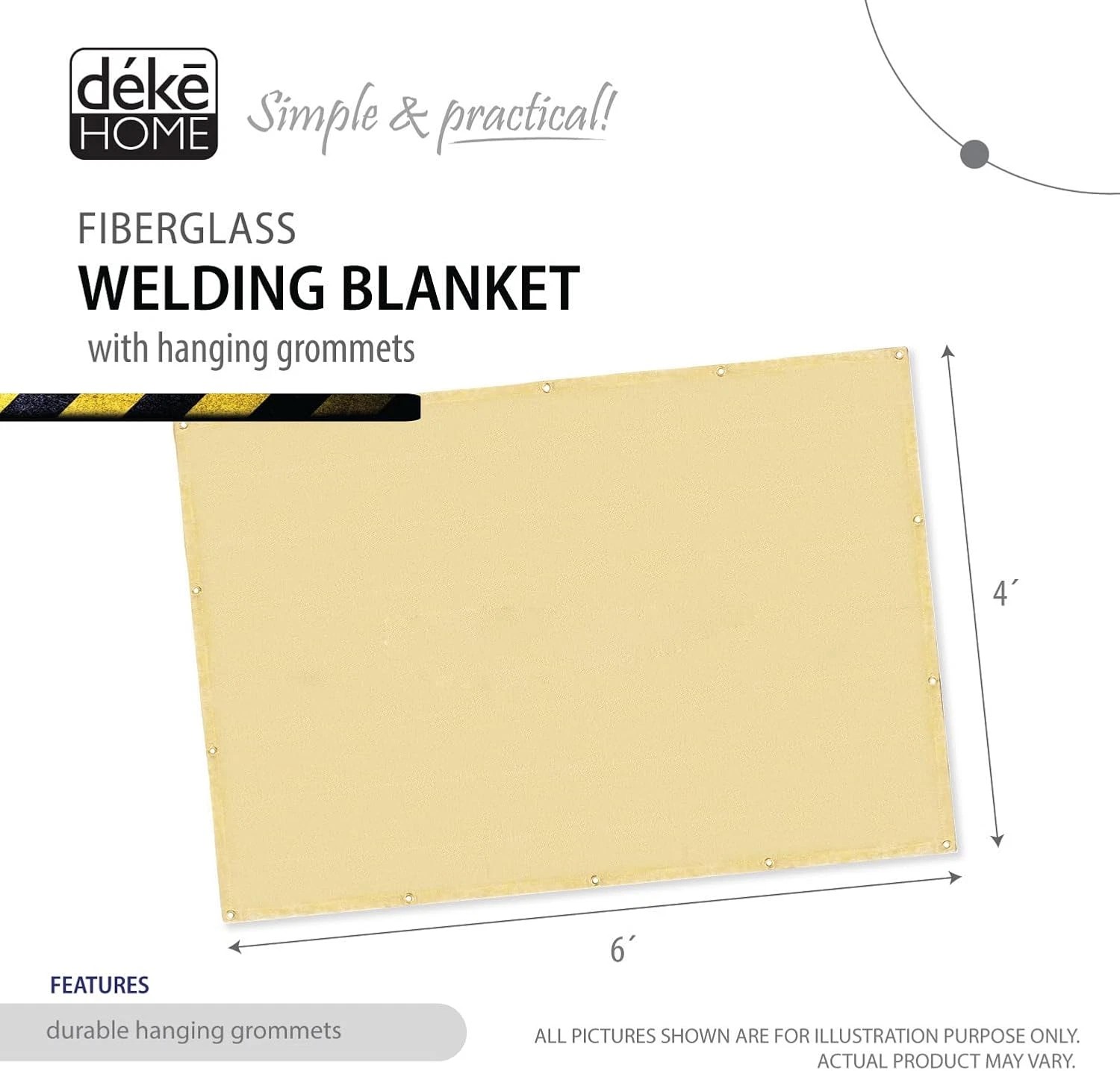

- Fiberglass:The most common material, offering excellent heat resistance at affordable prices

- Silica fabric:For extreme temperatures in foundries or welding operations

- Wool blends:Provide both fire resistance and insulation properties

- Ceramic fibers:Used in specialized high-temperature applications

When you place an industrial fire retardant blanket over a fire, it cuts off oxygen supply - one of the three elements fires need to burn. The dense weave prevents air circulation while resisting the flames.

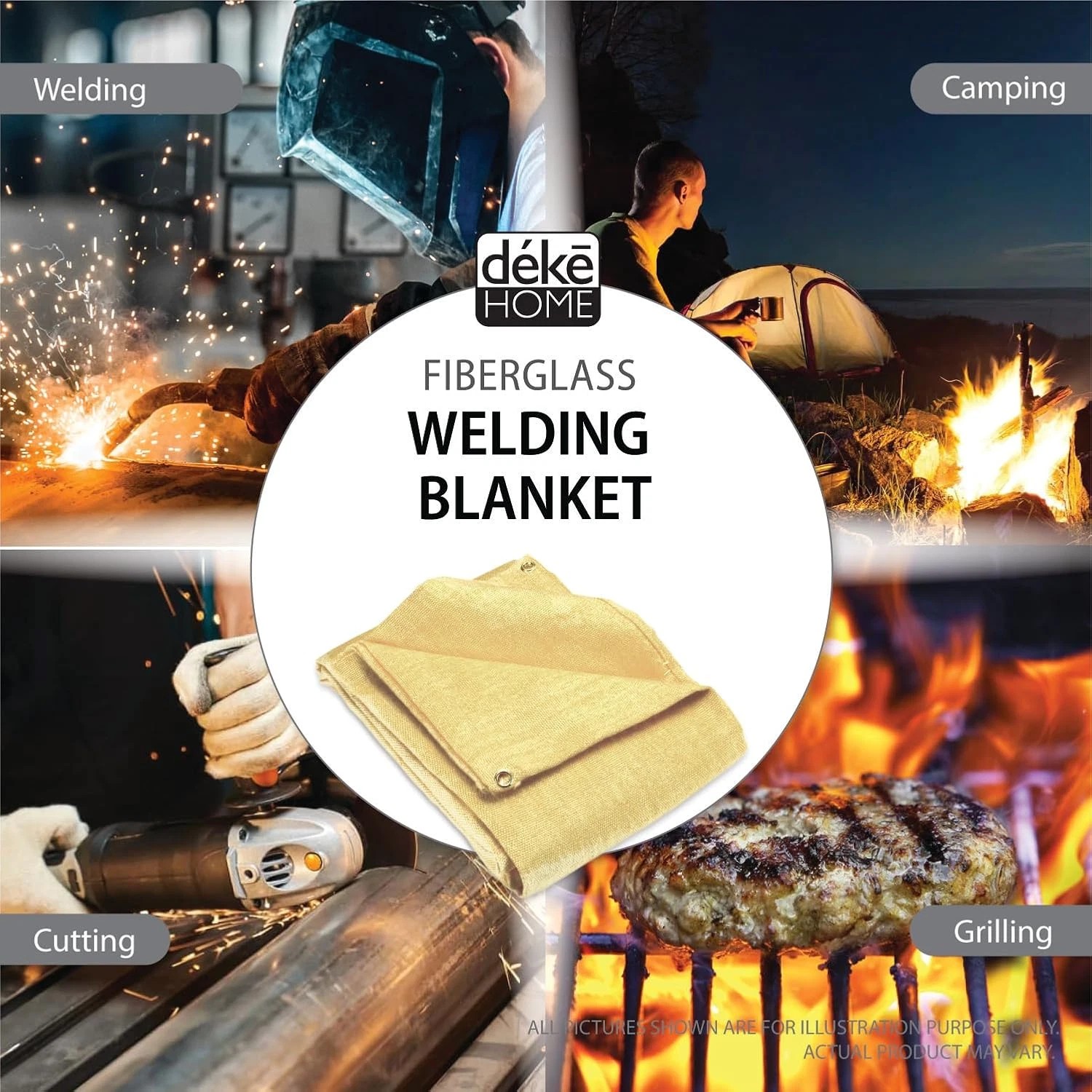

Primary Uses in Industrial Settings

You should keep these blankets accessible in several workplace scenarios:

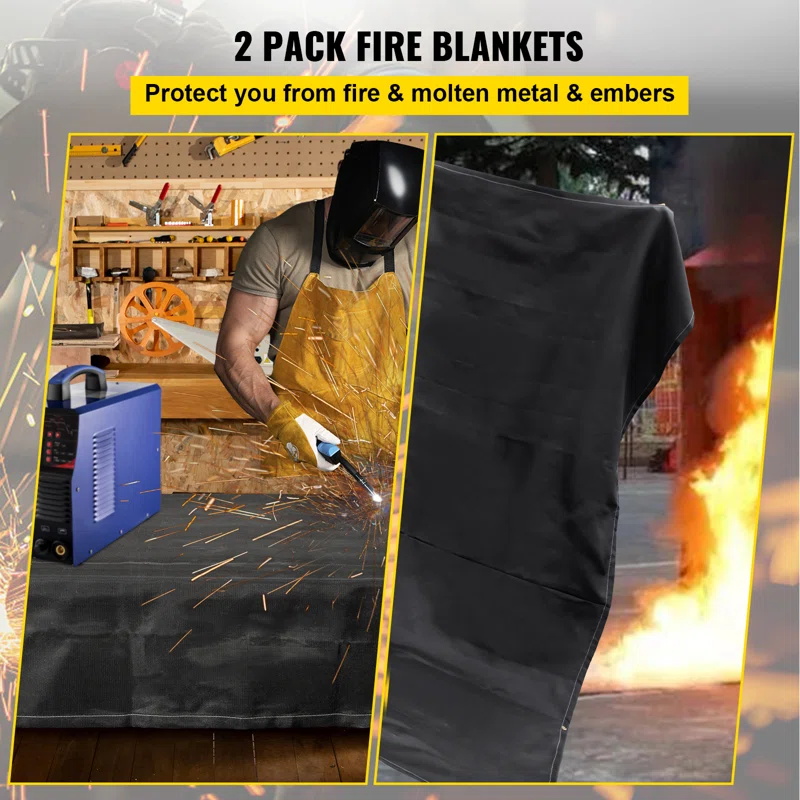

- Emergency fire suppression:Quickly smother small fires before they spread

- Personal protection:Workers can wrap themselves if caught near flames

- Equipment covering:Protect sensitive machinery from sparks or heat

- Welding operations:Contain sparks and prevent ignition of nearby materials

- Spill containment:Some models help control chemical spills

Choosing the Right Blanket for Your Needs

Selecting an industrial fire retardant blanket involves considering several factors:

- Size:Standard sizes range from 3'x3' to 8'x8'. Choose based on your largest potential fire risk

- Temperature rating:Match this to your workplace hazards (typically 500°F to 2000°F)

- Material:Fiberglass works for most applications, but specialized needs may require other materials

- Certifications:Look for NFPA 701, ASTM, or EN standards compliance

- Storage method:Wall-mounted cases or quick-release containers ensure fast access

Proper Maintenance and Care

To keep your industrial fire retardant blankets effective:

- Inspect monthly for tears, discoloration, or contamination

- Clean only according to manufacturer instructions - improper washing can damage fire resistance

- Store in dry, accessible locations away from direct sunlight

- Replace immediately if used in a fire or showing signs of damage

- Mark inspection dates on the storage container

Training Your Team

Simply having industrial fire retardant blankets isn't enough. Ensure your workers know:

- Where all blankets are located

- How to quickly remove them from containers

- Proper deployment techniques (approach from upwind, cover completely)

- When to use them versus other fire extinguishing methods

- Emergency procedures if the blanket doesn't fully extinguish the fire

Beyond Basic Fire Protection

Modern industrial fire retardant blankets offer additional benefits:

- Some include antimicrobial treatments for food processing facilities

- Electrostatic discharge versions protect sensitive electronics

- Chemical-resistant models handle hazardous material spills

- Lightweight designs improve portability without sacrificing protection

By understanding these aspects of industrial fire retardant blankets, you can make informed decisions about workplace safety. Remember that while these blankets are effective tools, they complement - rather than replace - comprehensive fire safety plans that include extinguishers, alarms, and evacuation procedures.