Welder Blankets: Essential Protection for Safe and Efficient Welding Work

Summary:Welder blankets protect surfaces from sparks and heat during welding. They're fire-resistant, durable, and come in various materials. This guide explains their benefits, types, and proper usage to enhance your welding safety and efficiency.

What Are Welder Blankets?

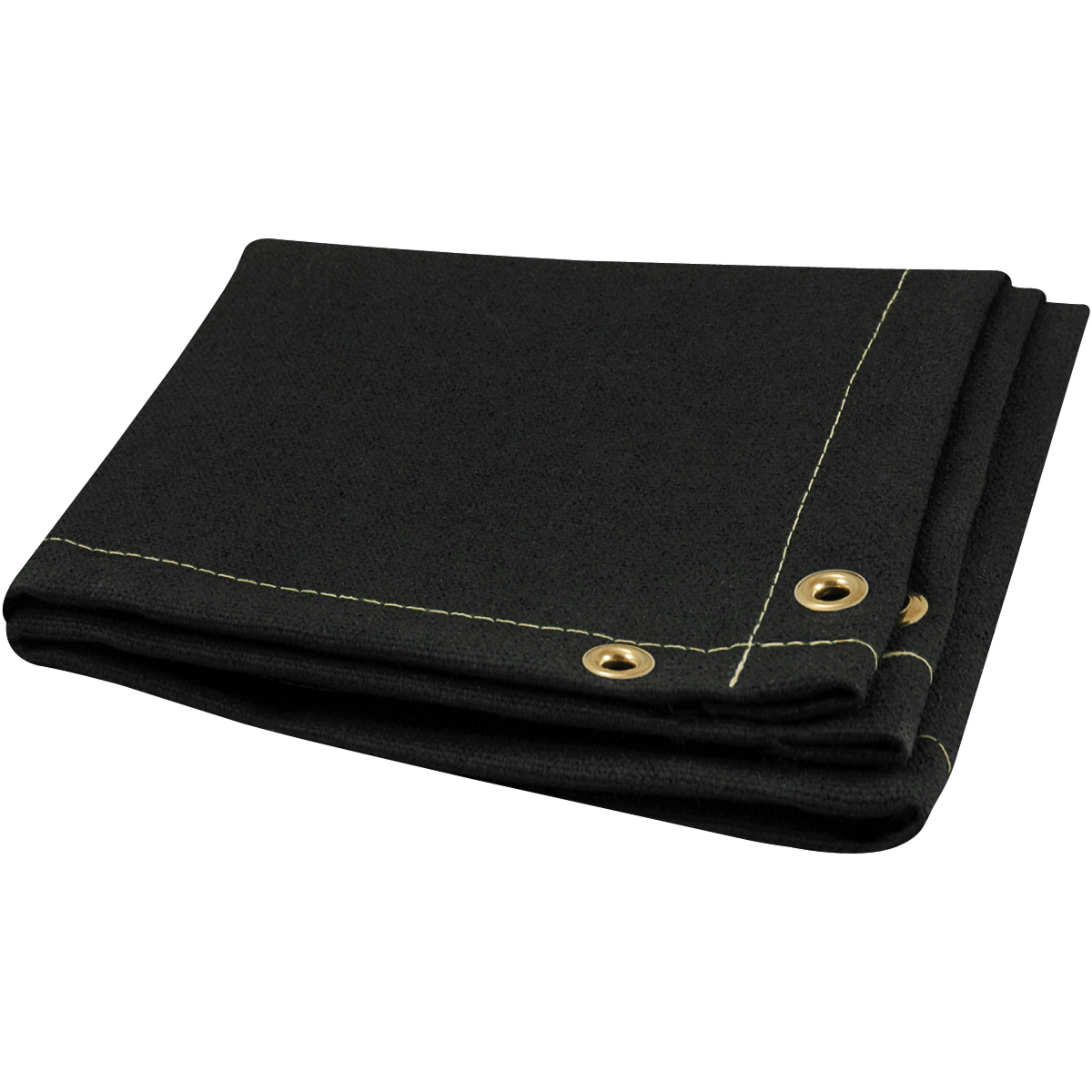

Welder blankets are specialized protective covers made from fire-resistant materials. You use them to shield floors, walls, and equipment from sparks, slag, and heat during welding operations. Unlike regular blankets, they can withstand extreme temperatures up to 1,800°F (982°C) without catching fire.

Key Benefits of Using Welder Blankets

1. Fire Prevention:They prevent accidental fires by containing sparks and molten metal splatter.

2. Surface Protection:Keep your work area clean and prevent damage to floors or valuable equipment.

3. Safety Compliance:Many worksites require welder blankets to meet OSHA safety standards.

4. Versatility:Use them for welding, grinding, cutting, or any hot work applications.

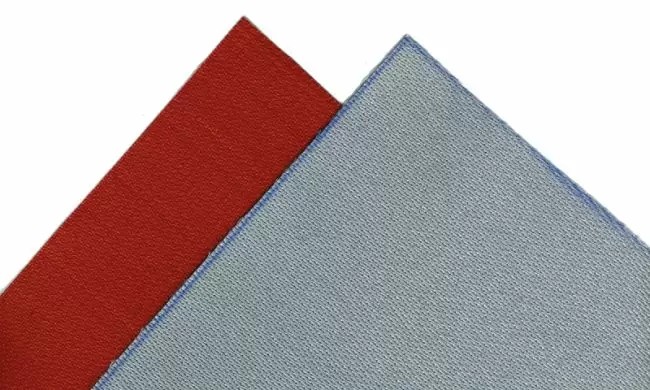

Types of Welder Blankets

Fiberglass Welder Blankets:The most common type, offering excellent heat resistance and durability. They're flexible and relatively lightweight.

Silica Welder Blankets:Provide higher temperature resistance (up to 2,000°F) but are more expensive.

Leather Welder Blankets:Used for heavy-duty applications where abrasion resistance is crucial.

Multi-Layer Blankets:Combine different materials for enhanced protection in extreme conditions.

How to Choose the Right Welder Blanket

Consider these factors when selecting a welder blanket:

1. Temperature Rating:Match it to your welding process (MIG, TIG, or stick welding produce different heat levels).

2. Size:Larger blankets cover more area but may be harder to handle.

3. Material:Fiberglass works for most applications, while silica handles extreme heat better.

4. Thickness:Thicker blankets last longer but are less flexible.

5. Edge Treatment:Look for reinforced edges that resist fraying.

Proper Use and Maintenance

To get the most from your welder blanket:

- Always inspect for holes or thin spots before use

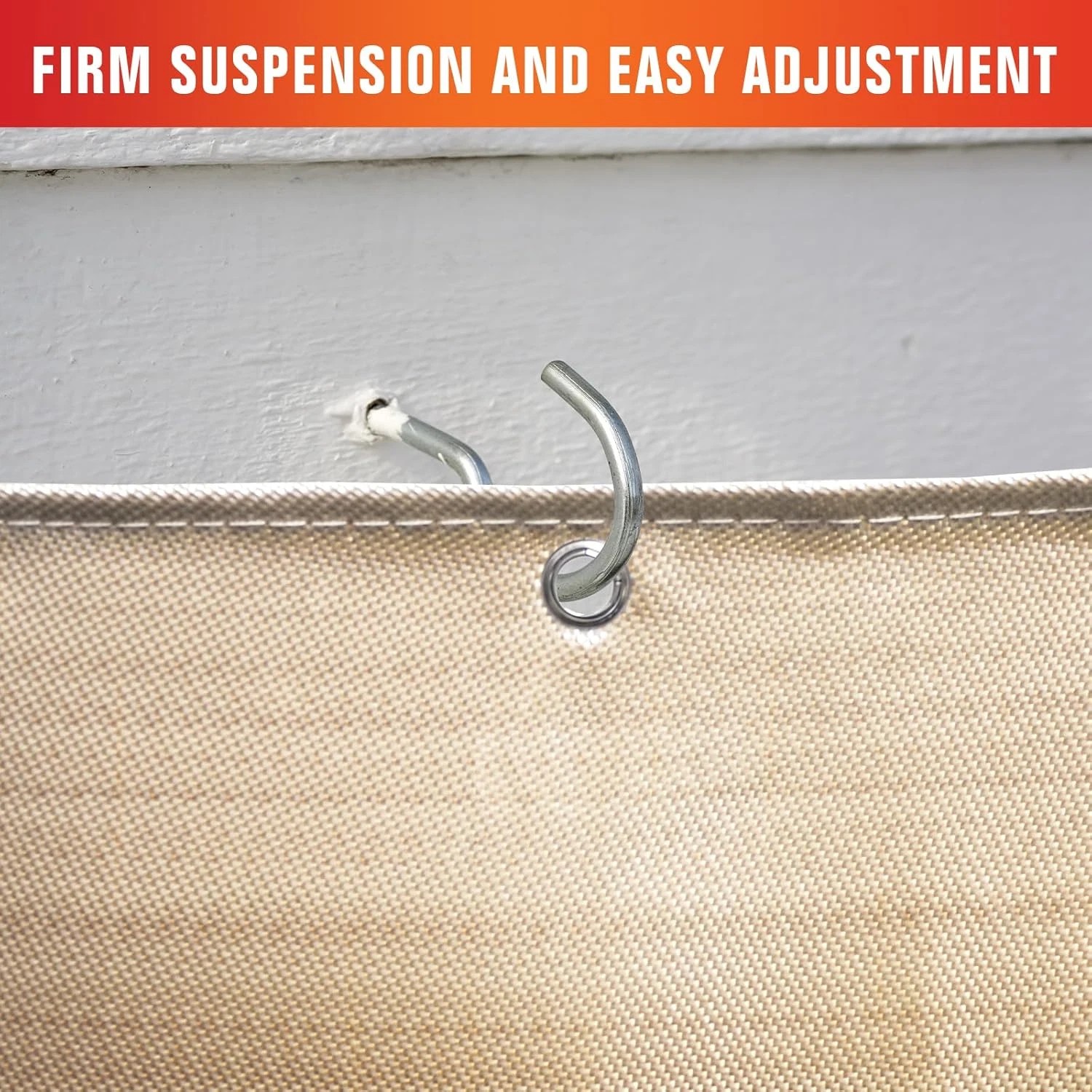

- Secure the blanket properly to prevent movement during work

- Keep it clean by shaking off debris regularly

- Store in a dry place away from chemicals

- Replace when you notice significant wear or reduced protection

Common Mistakes to Avoid

1. Using damaged blankets with holes or thin areas

2. Placing blankets too close to the welding arc (maintain proper distance)

3. Using the same blanket for different processes without checking temperature ratings

4. Folding or storing blankets while they're still hot

5. Assuming all welder blankets offer equal protection

Welder Blankets vs. Other Protection Methods

While welding curtains and screens have their place, welder blankets offer unique advantages:

- More flexible for covering irregular surfaces

- Better for floor protection

- Easier to reposition during work

- Provide insulation against heat transfer

Frequently Asked Questions

Q: Can I wash my welder blanket?A: Never machine wash. Shake off debris or use compressed air. For stubborn stains, consult the manufacturer.

Q: How long do welder blankets last?A: With proper care, 1-3 years depending on usage frequency and intensity.

Q: Are welder blankets reusable?A: Yes, they're designed for multiple uses unless severely damaged.

Q: Can I cut a welder blanket to size?A: Only if the manufacturer allows it. Cutting may compromise the edge protection.

Conclusion

Welder blankets are essential safety tools that protect your workspace and prevent fires. By choosing the right type and using it properly, you'll create a safer welding environment. Remember that no safety equipment replaces proper training and precautions, but quality welder blankets significantly reduce risks in your welding projects.