Warm Blankets for Welding Thermal Protection: Essential Safety Gear

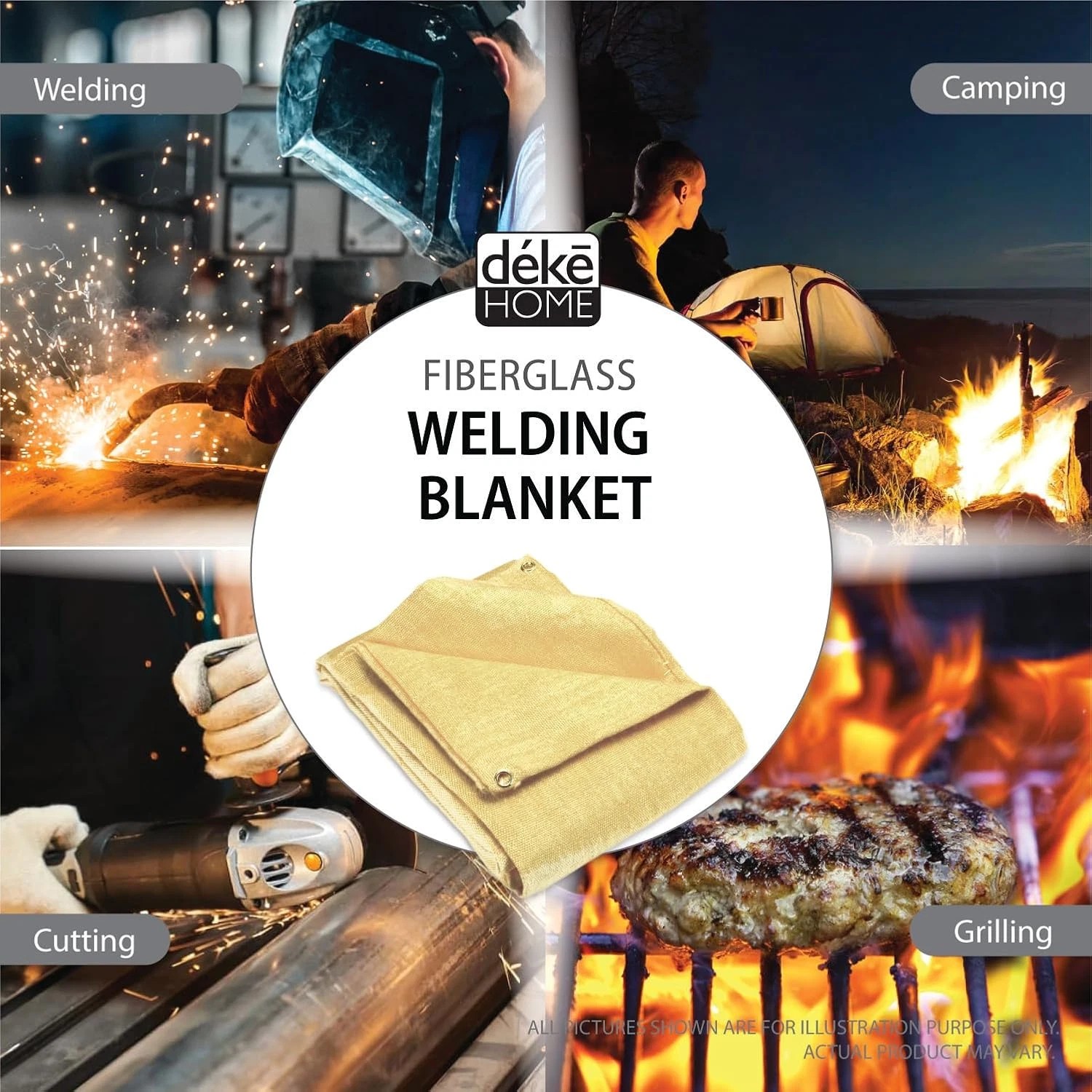

Welding generates extreme heat and sparks that require proper protection. Warm blankets for welding thermal control are specialized safety tools that shield workers and equipment from heat damage while maintaining comfort during cold conditions.

Why You Need Warm Blankets for Welding Thermal Management

When you're welding, temperatures can reach over 10,000°F (5,500°C). Standard blankets won't provide adequate protection. Warm blankets for welding thermal applications serve dual purposes:

- Protect against sparks and molten metal splatter

- Insulate against radiant heat transfer

- Maintain comfortable body temperature in cold environments

- Prevent heat loss from welded materials during cooling

Key Features of Quality Welding Thermal Blankets

Not all welding blankets are equal. Look for these essential features when selecting warm blankets for welding thermal protection:

- Heat-resistant materials:Typically fiberglass, silica, or ceramic fibers that withstand temperatures up to 2000°F (1100°C)

- Multi-layer construction:Combines heat reflection and absorption layers

- Flexibility:Allows easy draping over irregular surfaces

- Breathability:Prevents moisture buildup while working

- Reinforced edges:Metal grommets or stitching for durability

Proper Use of Warm Blankets in Welding Applications

To maximize safety and effectiveness when using warm blankets for welding thermal control:

- Inspect blankets before each use for tears or damage

- Cover all nearby flammable materials completely

- Overlap multiple blankets by at least 6 inches when covering large areas

- Secure blankets with welding clamps or non-flammable fasteners

- Allow proper ventilation to prevent heat buildup

Maintenance Tips for Welding Thermal Blankets

Proper care extends the life of your warm blankets for welding thermal protection:

- Shake out debris after each use

- Hand wash with mild detergent when needed (check manufacturer instructions)

- Air dry completely before storage

- Store folded or rolled in a dry, clean area

- Replace blankets showing significant wear or damage

Choosing Between Different Types of Welding Blankets

Consider these factors when selecting warm blankets for your welding thermal needs:

- Temperature rating:Match to your specific welding process

- Size:Ensure adequate coverage for your work area

- Weight:Lighter for draping, heavier for stationary protection

- Color:Darker colors absorb more radiant heat

- Certifications:Look for OSHA or ANSI compliance

Special Considerations for Cold Weather Welding

When working in low temperatures, warm blankets for welding thermal control become even more critical:

- Pre-warm materials to prevent cracking from thermal shock

- Use insulated blankets to maintain weld pool temperature

- Layer protection for both heat containment and worker warmth

- Monitor for condensation that could affect weld quality

- Allow extra cooling time due to ambient temperature differences

Innovations in Welding Thermal Protection

Recent advancements in warm blankets for welding thermal applications include:

- Phase-change materials that regulate temperature

- Smart fabrics with heat sensors

- Lightweight composite materials with higher temperature ratings

- Eco-friendly, recyclable insulation materials

- Integrated cooling channels for extreme heat applications

Investing in quality warm blankets for welding thermal protection ensures safety, improves work quality, and extends equipment life. Choose the right blanket for your specific welding needs and maintain it properly for optimal performance.