Welding Fireproof Blanket: Essential Safety Gear for Heat Protection

A welding fireproof blanket is a critical safety tool that protects against sparks, slag, and heat during welding. This guide explains its features, materials, uses, and how to choose the right one for your needs.

What Is a Welding Fireproof Blanket?

A welding fireproof blanket is a heat-resistant fabric designed to shield surfaces and workers from welding sparks, molten metal, and radiant heat. Made from materials like fiberglass or silica, it can withstand temperatures up to 2000°F (1093°C). Unlike regular blankets, it won't catch fire or melt when exposed to extreme heat.

Key Features of Quality Welding Fireproof Blankets

When selecting a welding fireproof blanket, look for these essential characteristics:

- High-temperature resistance(minimum 1000°F/538°C rating)

- Durable constructionwith reinforced edges

- Flexibilityfor easy shaping around workpieces

- Lightweightfor simple handling

- Chemical resistanceto common workshop substances

Common Uses for Welding Fireproof Blankets

These versatile safety tools have multiple applications:

- Workshop protection:Cover floors, walls, or equipment near welding areas

- Vehicle maintenance:Protect sensitive components during exhaust work

- Hot work permits:Required safety measure for many job sites

- Emergency situations:Can smother small fires caused by welding sparks

- Multi-process shielding:Useful for grinding and cutting operations too

How to Choose the Right Welding Fireproof Blanket

Consider these factors when purchasing:

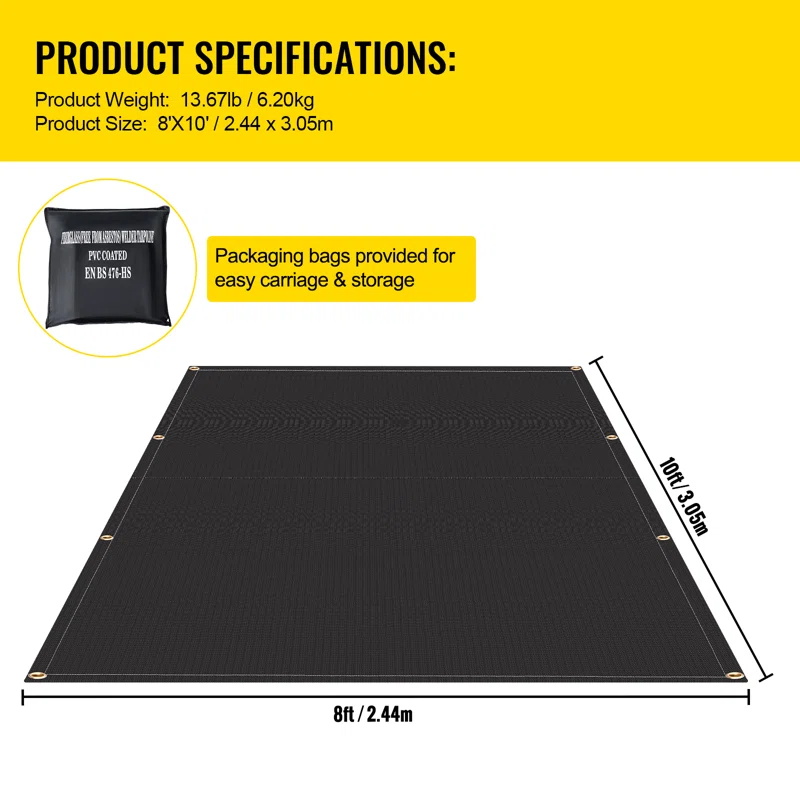

- Size:Measure your work area - common sizes range from 3'x3' to 10'x10'

- Material:Fiberglass is most common; silica offers higher temperature resistance

- Thickness:Thicker blankets (1/8" or more) provide better protection

- Color:Bright colors improve visibility in the workshop

- Certifications:Look for OSHA, ANSI, or NFPA compliance

Proper Use and Maintenance

To get the most from your welding fireproof blanket:

- Inspect regularly for tears or thin spots

- Clean with compressed air or a soft brush - avoid water

- Store flat or rolled - never fold sharply

- Replace if damaged or if fibers become brittle

- Use appropriate PPE (gloves) when handling hot blankets

Safety Tips When Using Welding Fireproof Blankets

While these blankets provide excellent protection, follow these precautions:

- Never leave a hot blanket unattended

- Allow proper cooling time before storage

- Combine with other fire safety measures like extinguishers

- Ensure complete coverage - gaps can allow sparks through

- Train all workers in proper blanket use and limitations

Welding Fireproof Blanket vs. Other Protection Methods

Compared to alternatives like metal shields or spray-on coatings, welding fireproof blankets offer:

- Better portability and flexibility

- Lower cost for large coverage areas

- Easier storage when not in use

- Reusability (unlike disposable sprays)

- Multi-purpose applications beyond just welding

Conclusion

A quality welding fireproof blanket is an indispensable safety tool for any welding operation. By understanding its features, proper use, and maintenance requirements, you can significantly reduce fire risks in your workshop. Always choose a blanket that meets your specific temperature and size needs, and remember that proper safety requires combining the blanket with other protective measures.