Welding Thermal Blanket: Ultimate Heat Protection Solution for Safe Welding

Welding thermal blankets shield surrounding areas from extreme heat and sparks during welding. These fire-resistant covers prevent damage to sensitive components and reduce workplace hazards. This guide explains their materials, applications, and proper usage for optimal protection.

What Is a Welding Thermal Blanket?

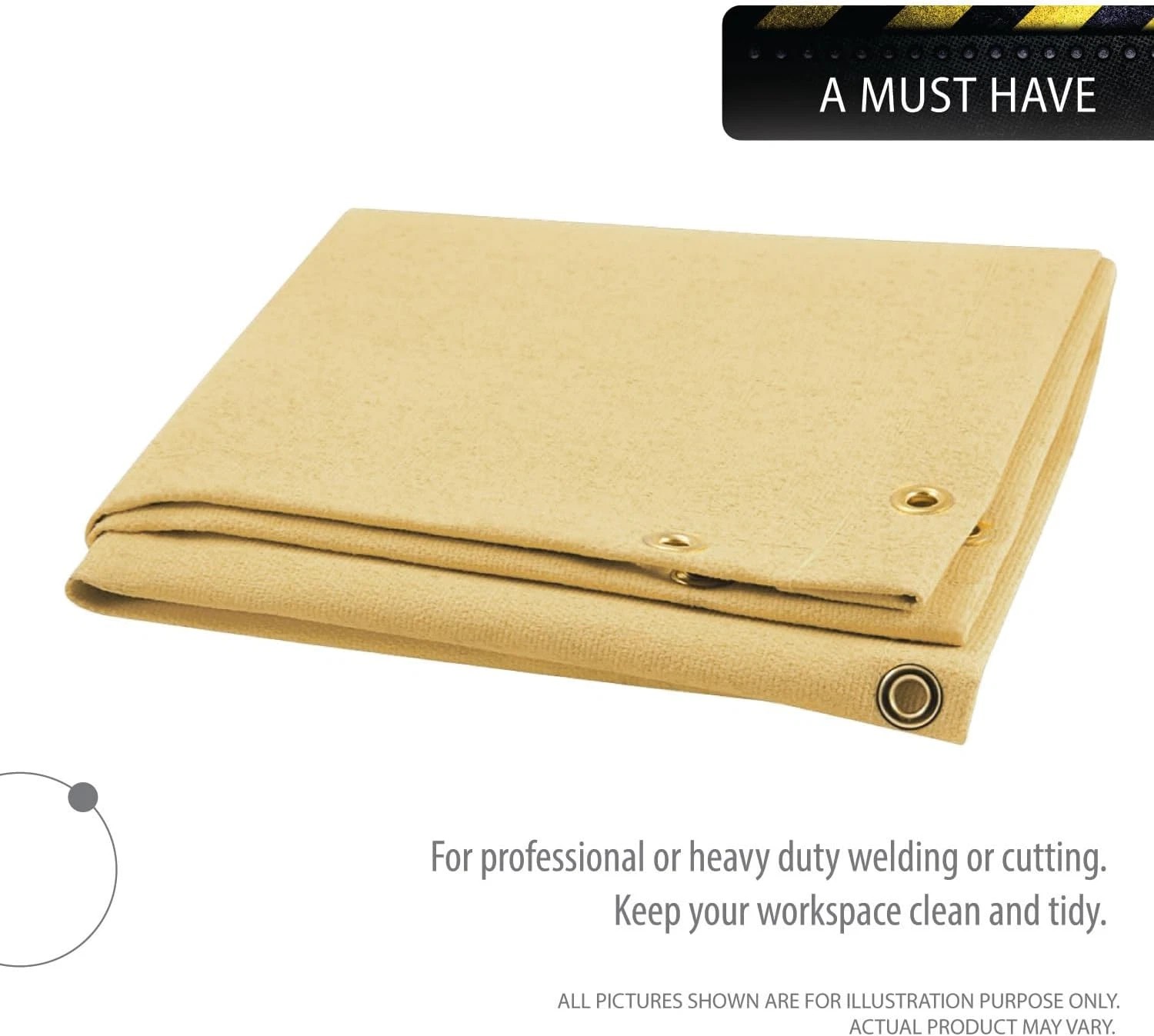

When you're welding, intense heat and sparks can damage nearby surfaces or start fires. A welding thermal blanket solves this problem. It's a flexible, heat-resistant barrier made from specialized materials that withstand temperatures up to 2000°F (1093°C). You simply place it over surfaces needing protection before starting your weld.

Modern welding blankets use advanced materials like fiberglass with silicone coatings or ceramic fibers. Unlike old asbestos blankets (now banned), these modern versions provide safe, effective protection without health risks. They're lightweight yet durable enough for daily industrial use.

Key Benefits of Using Welding Thermal Blankets

Why should you use a welding thermal blanket? Here are the top advantages:

- Fire prevention:Stops sparks and molten metal from igniting flammable materials

- Surface protection:Prevents heat damage to floors, walls, and equipment

- Safety compliance:Meets OSHA and other workplace safety standards

- Reusable:High-quality blankets last through hundreds of welding jobs

- Versatile:Works for MIG, TIG, arc welding, and plasma cutting

You'll especially appreciate welding thermal blankets when working in confined spaces or near expensive machinery. They create a safe zone around your work area with minimal setup time.

Choosing the Right Welding Thermal Blanket

Not all welding blankets offer equal protection. Consider these factors when selecting yours:

Temperature Rating

Match the blanket's maximum temperature rating to your welding process. Standard fiberglass blankets handle 1000°F (538°C), while premium ceramic fiber versions withstand 2000°F+ (1093°C+). For occasional light welding, standard blankets work fine. For continuous heavy-duty use, invest in higher-rated protection.

Material Composition

Today's welding thermal blankets come in three main types:

- Fiberglass:Most affordable option, good for general purpose use

- Silicone-coated fiberglass:More durable with better heat reflection

- Ceramic fiber:Highest heat resistance, ideal for industrial applications

Size and Thickness

Measure your typical work area and add safety margins. Common sizes range from 3'x3' for small jobs to 10'x10' for large projects. Thickness affects durability - standard is 1/16", heavy-duty versions go up to 1/4". Thicker blankets last longer but are less flexible.

Proper Use and Maintenance

To get maximum value from your welding thermal blanket:

- Inspect for damage before each use - replace if you see holes or fraying

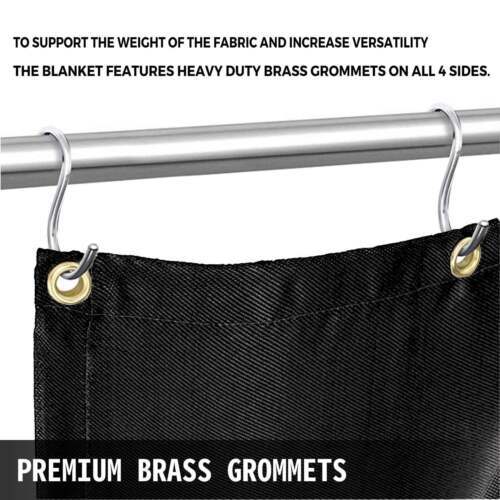

- Secure edges with weights or clips to prevent lifting from heat currents

- Allow proper overlap when using multiple blankets (minimum 6 inches)

- Clean with compressed air - never wash with water or chemicals

- Store flat or rolled - avoid folding to prevent material fatigue

Remember that welding blankets are heat resistant, not heat proof. Avoid direct contact with the welding arc or prolonged exposure to maximum temperatures. Rotate the blanket periodically to distribute wear evenly.

Special Applications

Beyond standard welding protection, thermal blankets serve specialized purposes:

Pipe Welding

Wrap-around welding blankets with Velcro or buckle closures protect pipes during circumferential welding. These prevent heat damage to painted surfaces or insulation while allowing full access to the weld joint.

Aerospace and Automotive

Ultra-thin, high-temperature blankets protect delicate electronics and composite materials during aircraft or vehicle repairs. These often combine ceramic fibers with reflective metalized surfaces.

Foundry Work

Extra-heavy welding blankets handle molten metal spills in foundries. Look for reinforced edges and multiple layers for this demanding application.

Safety Considerations

While welding thermal blankets significantly improve safety, follow these additional precautions:

- Always wear proper PPE (gloves, helmet, protective clothing)

- Maintain adequate ventilation - blankets don't protect against fumes

- Keep fire extinguishers accessible

- Never leave hot blankets unattended - they retain heat for hours

- Train all workers in proper blanket usage and limitations

By combining welding thermal blankets with standard safety practices, you create the safest possible environment for high-temperature metalwork.

Conclusion

A quality welding thermal blanket is one of the smartest investments for any welding professional. It protects your work area, prevents costly damage, and reduces fire risks - all while complying with safety regulations. Choose the right material and size for your specific needs, maintain it properly, and you'll enjoy years of reliable service. Whether you're a hobbyist or industrial welder, these essential safety tools belong in your equipment collection.