Welding Blankets South Africa: Your Essential Heat Protection Solution

Summary:Welding blankets in South Africa protect against sparks, heat, and molten metal. This guide covers types, materials, safety standards, and where to buy quality welding blankets locally.

Why You Need Welding Blankets in South Africa

If you work with welding equipment in South Africa, proper safety gear is non-negotiable. Welding blankets create a protective barrier against sparks (up to 3000°F), molten metal splatter, and accidental fires. They're essential for automotive workshops, construction sites, and metal fabrication businesses across Johannesburg, Cape Town, and Durban.

Types of Welding Blankets Available in South Africa

South African suppliers typically offer three main types:

- Fiberglass blankets:Most common, withstand 1000°F-1800°F

- Silica blankets:For extreme heat (up to 3000°F)

- Multi-layer blankets:Combine fiberglass with aluminized coating

For shipbuilding or mining applications near Richards Bay, silica blankets are recommended due to higher heat resistance.

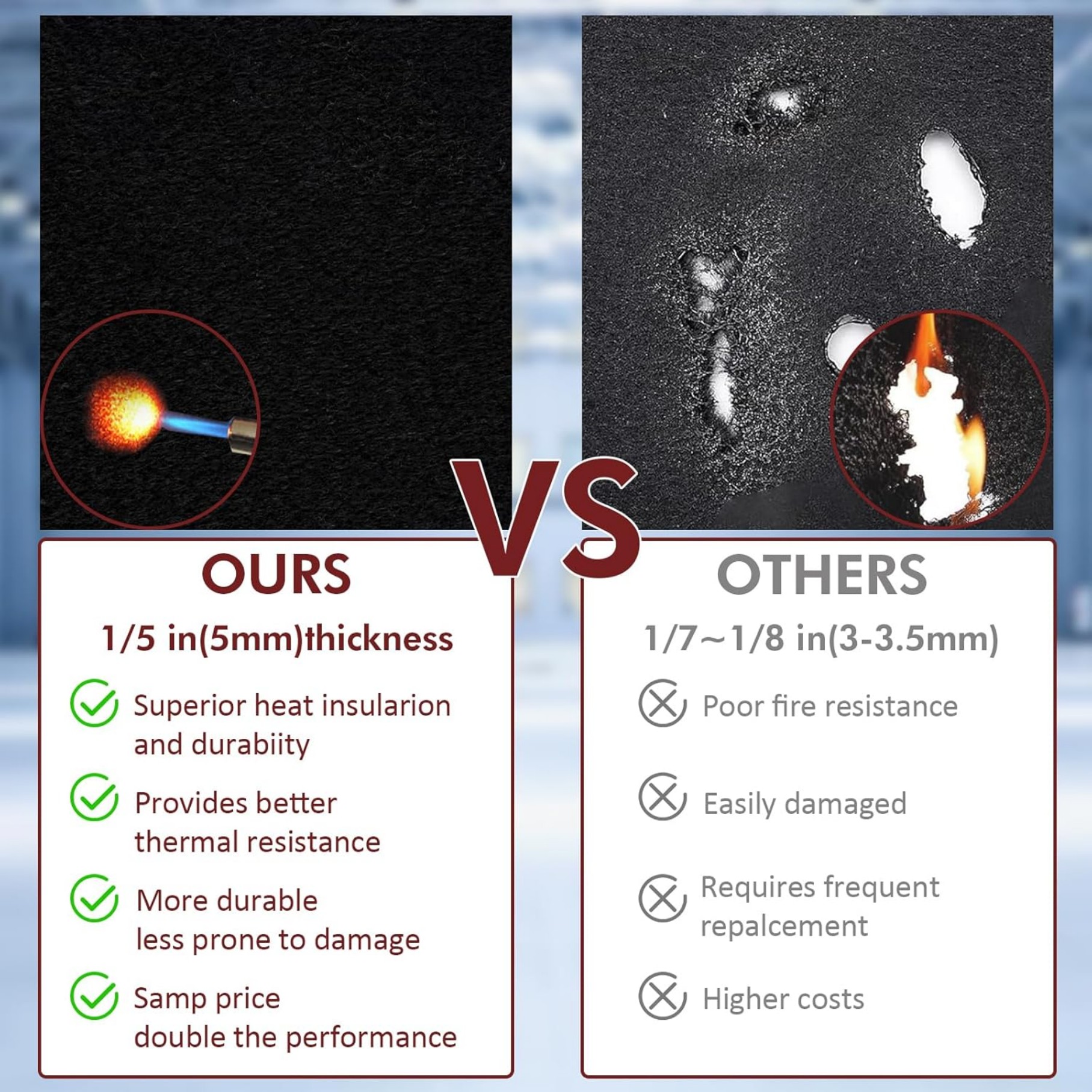

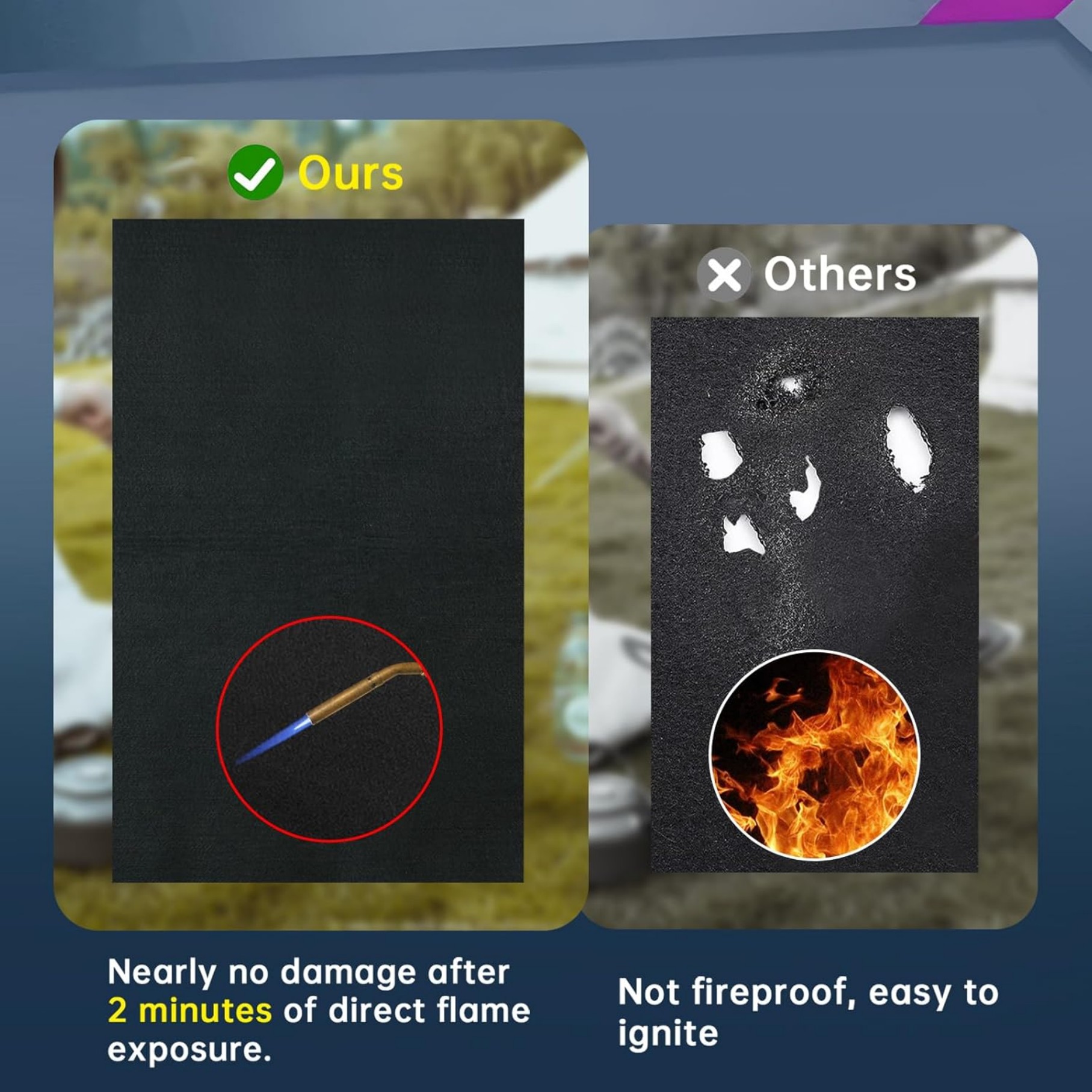

Key Features to Look For

When buying welding blankets in South Africa, check:

- SABS/ISO certification for fire resistance

- Reinforced grommets for secure hanging

- UV resistance for outdoor use (important in high-sun areas)

- Flexibility at low temperatures (relevant for Highveld winters)

Proper Use and Maintenance

To maximize your welding blanket's lifespan:

- Inspect for damage before each use

- Store folded (not rolled) to prevent fiber breakage

- Clean with compressed air - never wash with water

- Replace if you notice thinning or holes

Many South African workshops make the mistake of using damaged blankets, compromising safety.

Where to Buy Quality Welding Blankets in South Africa

Reliable suppliers include:

- Specialized safety equipment stores in industrial areas

- Online marketplaces with verified SABS certifications

- Direct from manufacturers with local warehouses

Always request test certificates - genuine welding blankets undergo rigorous spark and flame tests.

Cost Considerations

Prices range from R800-R5000 depending on:

- Size (standard is 1.8m x 2m)

- Material thickness (measured in grams per square meter)

- Brand reputation

While cheaper imports exist, locally certified welding blankets offer better protection and last 3-5 years with proper care.

Industry-Specific Applications

In South Africa, welding blankets are crucial for:

- Mining:Protecting equipment during on-site repairs

- Automotive:Shielding vehicles during exhaust work

- Construction:Creating safe welding zones on high-rises

The Western Cape's ship repair industry particularly benefits from extra-large (3m x 4m) blankets.

Safety Regulations in South Africa

The Occupational Health and Safety Act requires:

- Fire-resistant barriers within 10m of welding areas

- Daily inspection of protective equipment

- Proper training in heat protection gear use

Non-compliance can result in fines up to R100,000 under the OHS Act.

Alternatives to Traditional Blankets

For specialized needs:

- Welding curtains:For stationary work areas

- Aluminized pads:For small, precise work

- Custom-cut blankets:Available from some Gauteng suppliers

However, standard welding blankets remain the most versatile solution for most South African workshops.

Final Tip:Always keep two blankets - one for immediate use and a backup. South Africa's lead times for replacements can vary, especially in remote areas.