Hi Temp Welding Blanket Guide: Safety & Usage Tips for Hot Work

Summary:Hi temp welding blankets protect against sparks, slag, and heat in welding projects. This guide explains their materials, temperature ratings, proper use, and maintenance for optimal safety and performance.

What Is a Hi Temp Welding Blanket?

When you're welding, cutting, or doing any hot work, a hi temp welding blanket is your first line of defense. These specialized covers are made from heat-resistant materials like fiberglass or silica fabrics that can withstand extreme temperatures up to 2,000°F (1,093°C) or more.

Why You Need a Hi Temp Welding Blanket

Every year, welding accidents cause serious fires and injuries. A quality hi temp welding blanket:

- Protects flammable surfaces from sparks and molten metal

- Contains heat within your work area

- Prevents accidental burns on nearby equipment

- Meets OSHA safety requirements for hot work

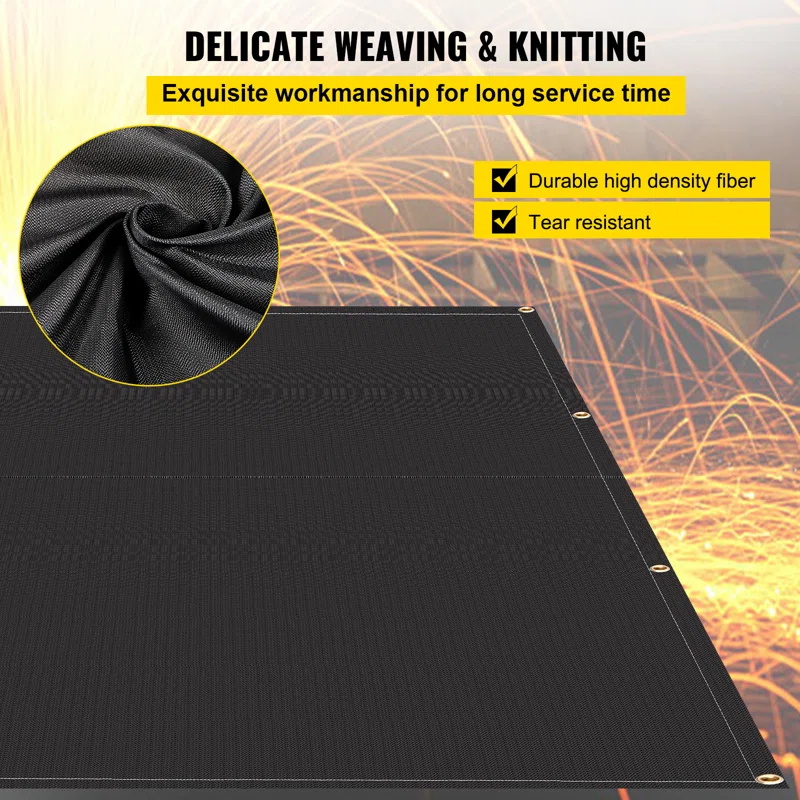

Choosing the Right Welding Blanket

Not all hi temp welding blankets are equal. Consider these factors:

- Temperature rating:Match it to your welding process (MIG/TIG welding needs higher ratings than soldering)

- Material:Fiberglass is common; silica offers higher protection; some have aluminum coatings

- Size:Measure your work area - standard sizes range from 4'x4' to 10'x10'

- Thickness:Thicker blankets (1/4"+) last longer but are less flexible

Proper Use of Your Welding Blanket

To get maximum protection from your hi temp welding blanket:

- Always overlap multiple blankets by at least 6 inches if covering large areas

- Secure edges with welding blanket clips or weights

- Keep the blanket at least 12 inches away from the actual weld point

- Never use a damaged blanket - inspect for holes before each use

Maintenance Tips

With proper care, your hi temp welding blanket lasts longer:

- Shake off slag and debris after each use

- Store flat or rolled - never fold (creases weaken fibers)

- Wash only when necessary with mild soap and water

- Replace when you see significant fiber breakdown or holes

Beyond Welding: Other Uses

Your hi temp welding blanket is versatile:

- Grinding operations

- Foundry work

- Fireplace protection

- Emergency fire containment

- Hot pipe insulation

Safety First

Remember that while hi temp welding blankets reduce risks, they don't eliminate all dangers:

- Always have a fire extinguisher nearby

- Wear proper PPE (gloves, apron, face shield)

- Work in well-ventilated areas

- Allow blankets to cool completely before handling

FAQs About Hi Temp Welding Blankets

Q: Can welding blankets catch fire?A: Quality blankets won't combust but can degrade over time with direct flame contact.

Q: How long do they last?A: With proper care, 1-3 years depending on usage frequency.

Q: Are they toxic when heated?A: Reputable brands use non-toxic materials that won't release harmful fumes.

Investing in a proper hi temp welding blanket protects your workspace, equipment, and most importantly - you. Choose quality, use it correctly, and maintain it well for years of safe hot work.