Padded Welding Blankets: Protection & Safety for Industrial Work

Summary:Padded welding blankets protect surfaces from sparks and heat during welding. They're flame-resistant, durable, and essential for safety in metalwork. This guide explains their benefits, materials, and proper use.

Why You Need Padded Welding Blankets

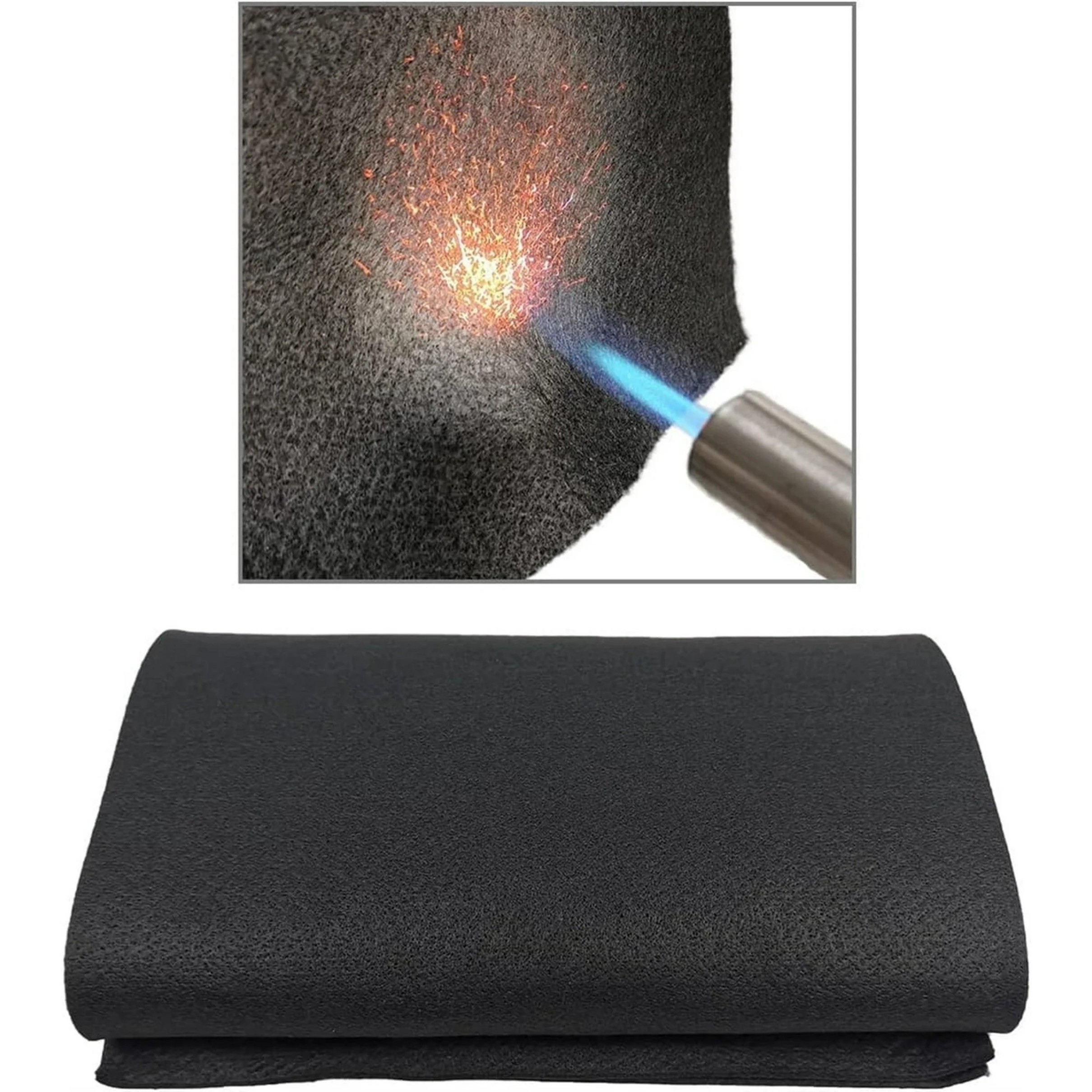

When you're welding, sparks and molten metal can damage floors, equipment, or nearby materials. Padded welding blankets create a protective barrier. Unlike regular tarps, they have heat-resistant layers that won't melt or catch fire. You'll prevent costly damage and reduce fire risks.

Key Features of Quality Padded Welding Blankets

Look for these characteristics:

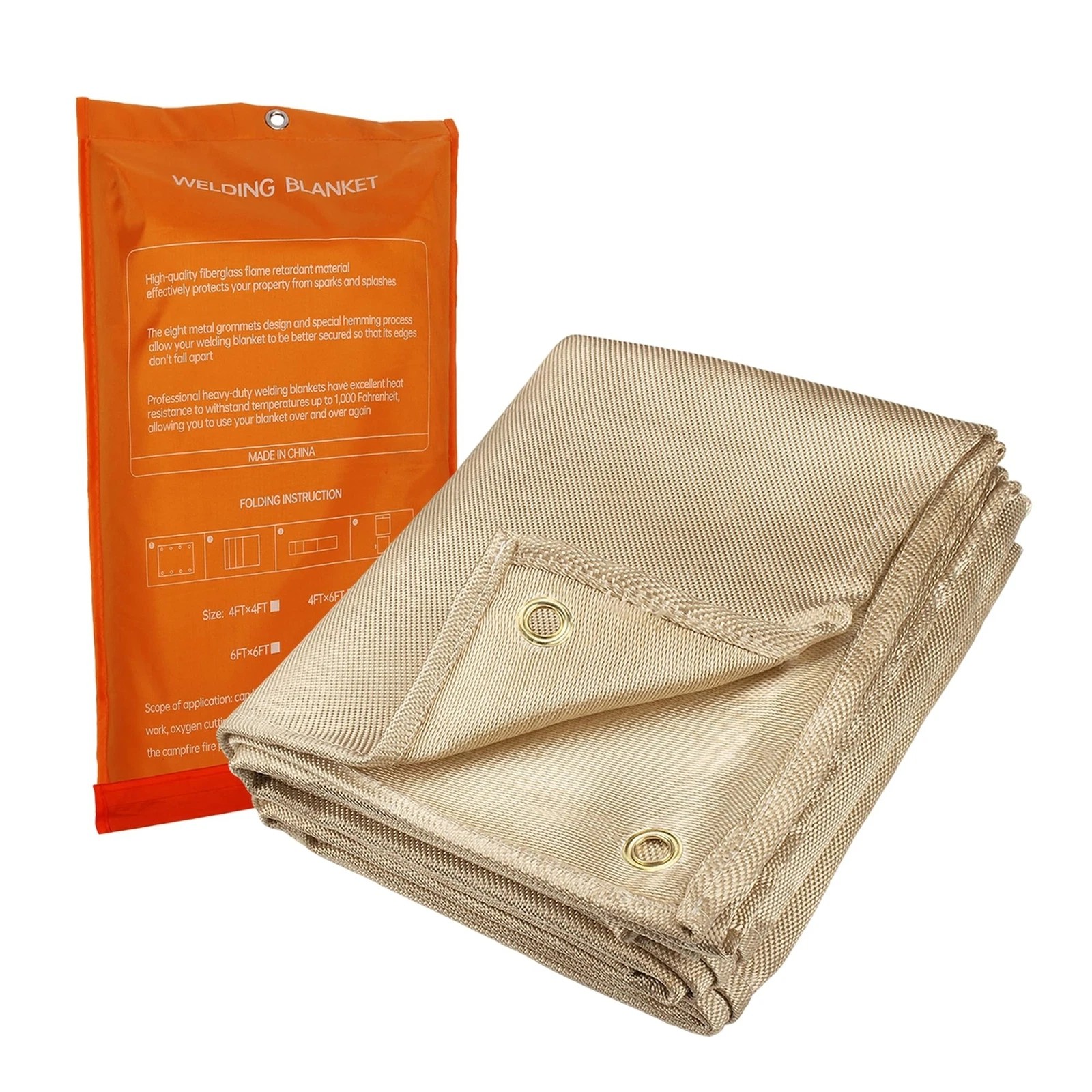

- Material:Fiberglass or silica fabric with padding absorbs impact

- Thickness:1/4" to 1/2" padding provides optimal protection

- Temperature rating:Should withstand at least 1,800°F (982°C)

- Size options:From 3'x3' for small jobs to 12'x12' for large areas

How to Use Padded Welding Blankets Safely

Follow these steps for maximum protection:

- Clear the work area of flammable materials

- Lay the blanket flat with no folds or wrinkles

- Overlap multiple blankets by 6 inches if covering large areas

- Secure edges with weights or non-flammable clips

- Inspect after each use for burns or damage

Maintenance Tips for Longevity

Proper care extends your padded welding blanket's life:

- Shake off debris after use - never brush aggressively

- Store flat or rolled in a dry, cool place

- Wash only when necessary with mild detergent (check manufacturer instructions)

- Replace when padding becomes compressed or outer layer shows significant wear

Padded vs. Non-Padded Welding Blankets

Standard welding blankets protect against sparks but lack impact absorption. Padded versions offer:

| Feature | Padded | Non-Padded |

|---|---|---|

| Spark protection | Yes | Yes |

| Heat insulation | Superior | Basic |

| Dropped tool protection | Yes | No |

| Surface marring prevention | Yes | Limited |

Common Applications

Padded welding blankets are versatile:

- Automotive shops:Protecting painted surfaces during exhaust work

- Construction sites:Covering wooden floors during metal framing

- Manufacturing:Safeguarding precision equipment near welding stations

- Shipyards:Preventing deck damage during repairs

Choosing the Right Blanket

Consider these factors:

- Work type:Heavy industrial jobs need thicker padding

- Frequency of use:Professional welders should invest in commercial-grade blankets

- Environment:Outdoor use requires UV-resistant materials

- Mobility needs:Some blankets come with carrying cases

Padded welding blankets are a smart investment for any metalworker. They provide superior protection compared to standard blankets and help maintain a safer work environment. Choose quality materials and proper sizing for your specific needs, and always follow safety protocols when welding.