Valve Fire Blankets: Essential Protection for Industrial Safety | Complete Guide

Valve fire blankets are specialized safety devices that protect industrial valves from fire damage. This guide explains their materials, applications, installation, and maintenance to help you choose and use them effectively in hazardous environments.

What Are Valve Fire Blankets?

Valve fire blankets are flame-resistant covers designed specifically for industrial valves. They create a protective barrier against extreme heat and flames, preventing valve failure during fires. Unlike regular fire blankets, these are shaped to fit valves precisely while allowing operation access.

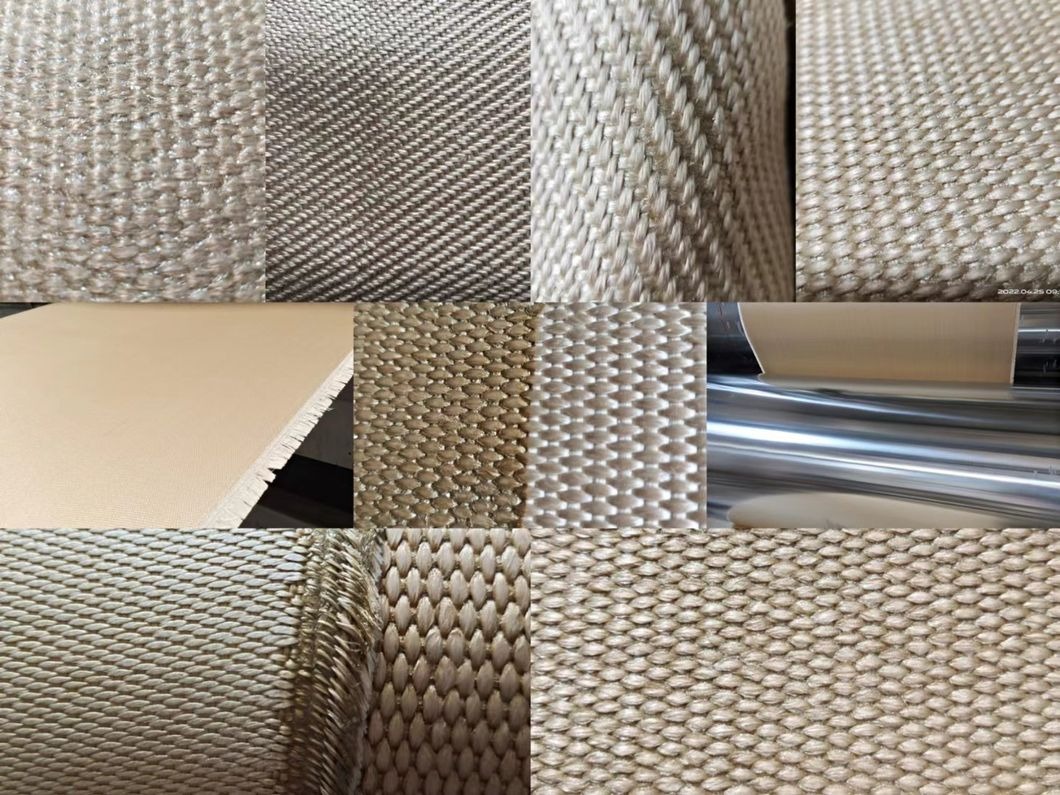

Key Materials and Construction

Quality valve fire blankets typically use:

- Fiberglass fabric:Withstands temperatures up to 1000°C (1832°F)

- Silicone coating:Provides water and chemical resistance

- Stainless steel fasteners:Ensure secure attachment without corrosion

- Multi-layer design:Combines heat reflection and insulation

Critical Applications

You need valve fire blankets in these situations:

- Oil and gas facilities:Protect critical shutoff valves in refineries

- Chemical plants:Prevent hazardous material leaks during fires

- Power stations:Maintain control of steam and fuel systems

- Marine applications:Protect engine room valves on ships

Installation Best Practices

Follow these steps for proper valve fire blanket installation:

- Clean the valve surface thoroughly before installation

- Position the blanket to cover all vulnerable components

- Secure all fasteners according to manufacturer specifications

- Ensure operational handles remain accessible

- Check for proper clearance from adjacent equipment

Maintenance and Inspection

To keep your valve fire blankets effective:

- Inspect monthly for tears, fraying, or contamination

- Clean with mild detergent if soiled (check manufacturer guidelines)

- Replace immediately if damaged or after fire exposure

- Document all inspections for safety compliance

Selecting the Right Valve Fire Blanket

Consider these factors when choosing:

- Temperature rating:Must exceed your facility's maximum fire risk

- Chemical resistance:Match to your processing chemicals

- Valve type compatibility:Gate, ball, butterfly valves need different designs

- Certifications:Look for UL, FM, or EN standards compliance

Common Mistakes to Avoid

Don't compromise safety with these errors:

- Using generic fire blankets instead of valve-specific designs

- Installing damaged or improperly sized blankets

- Blocking valve operation mechanisms

- Neglecting regular inspections

- Mixing incompatible cleaning chemicals

Emergency Response Considerations

Remember these points during fire incidents:

- Valve fire blankets buy critical time but aren't permanent solutions

- Trained personnel should still attempt controlled shutdowns when safe

- Never remove a blanket during active firefighting

- Plan evacuation routes that don't rely on protected valves alone

Cost vs. Benefit Analysis

While valve fire blankets represent an investment, they:

- Prevent catastrophic system failures

- Reduce downtime after incidents

- Lower insurance premiums in many cases

- Demonstrate safety commitment to regulators

By understanding and properly implementing valve fire blankets, you significantly enhance your facility's fire protection strategy. These specialized safety devices serve as your first line of defense against valve-related fire hazards, protecting both equipment and personnel.