Heat Blanket for Welding: Essential Guide for Safe and Efficient Welding Operations

Welding heat blankets protect surfaces from sparks, slag, and heat damage. This guide explains their types, materials, proper usage, and maintenance to enhance your welding safety and efficiency while preventing costly damage to surrounding areas.

What Is a Heat Blanket for Welding?

A heat blanket for welding is a protective cover made from flame-resistant materials that shields surrounding surfaces from welding sparks, molten metal, and radiant heat. These specialized blankets are essential when working near flammable materials or when you need to protect sensitive equipment from heat damage.

Welding blankets come in various sizes, thicknesses, and materials to suit different welding applications. They're designed to withstand temperatures up to 3000°F (1650°C) for short exposures, making them ideal for most welding processes including MIG, TIG, stick, and plasma cutting.

Key Benefits of Using a Welding Heat Blanket

Using a proper heat blanket for welding offers multiple advantages:

- Fire prevention:Contains sparks and prevents ignition of nearby combustible materials

- Surface protection:Shields floors, walls, and equipment from heat damage and spatter

- Safety compliance:Helps meet OSHA and workplace safety requirements

- Cost savings:Reduces damage to work areas and equipment

- Versatility:Can be used as curtains, floor covers, or wrap-around protection

Types of Welding Heat Blankets

Choose the right heat blanket for your welding needs:

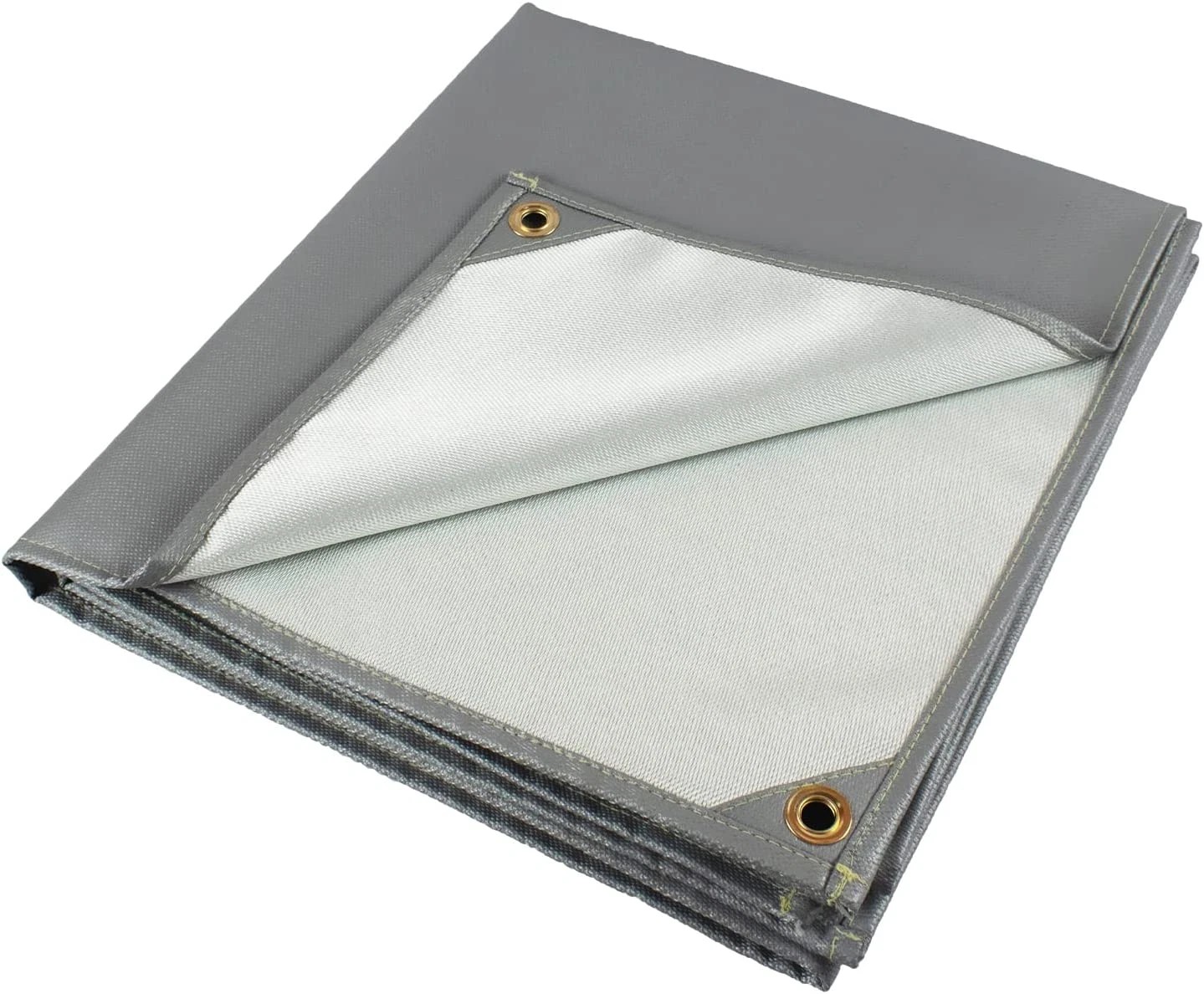

Fiberglass Welding Blankets

The most common type, made from woven fiberglass with silicone coating. They're flexible, durable, and withstand temperatures up to 1000°F (538°C) continuously. Ideal for general welding applications.

Silica Welding Blankets

Made from amorphous silica fibers, these offer superior heat resistance up to 2000°F (1093°C). They're more expensive but necessary for high-temperature welding like plasma cutting.

Ceramic Fiber Blankets

For extreme heat applications, ceramic fiber blankets can handle up to 3000°F (1650°C). They're lightweight but more fragile than other types.

Multi-Layer Composite Blankets

Combine different materials for optimal protection. Often feature an outer abrasion-resistant layer with inner heat-reflective layers.

How to Properly Use a Welding Heat Blanket

To maximize protection from your heat blanket for welding:

- Select the appropriate blanket type for your welding temperature

- Ensure complete coverage of protected areas with overlap

- Secure the blanket firmly to prevent movement during work

- Keep the blanket clean from oil and grease buildup

- Inspect regularly for tears or thinning areas

- Replace when showing significant wear or damage

Maintenance and Care Tips

Proper care extends your welding heat blanket's lifespan:

- Shake off slag and debris after each use

- Store folded or rolled in a dry location

- Wash only when necessary using mild detergent

- Avoid sharp objects that could puncture the material

- Never use damaged blankets - replace immediately

Choosing the Right Size and Thickness

Consider these factors when selecting your heat blanket for welding:

- Work area size:Measure the space needing protection

- Welding process:Higher heat processes need thicker blankets

- Mobility needs:Larger blankets may be harder to position

- Durability:Thicker blankets last longer but are less flexible

Common sizes range from 3'x3' for small jobs to 12'x12' for large work areas. Thickness typically varies from 1/16" to 1/4".

Safety Considerations

While heat blankets significantly improve safety, remember:

- No blanket is 100% spark-proof - maintain proper fire watches

- Keep flammable materials away even when using blankets

- Wear appropriate PPE in addition to using blankets

- Ensure proper ventilation when welding under confined blankets

- Follow all manufacturer's safety guidelines

Alternative Uses for Welding Heat Blankets

Beyond welding, these versatile blankets can:

- Protect surfaces during grinding or cutting operations

- Serve as emergency fire blankets

- Provide insulation for hot workpieces

- Create temporary heat barriers in industrial settings

- Protect vehicle interiors during mobile welding repairs

Conclusion

A quality heat blanket for welding is an essential safety tool that protects your work area and prevents costly damage. By selecting the right type, size, and thickness for your specific needs, and maintaining it properly, you'll enhance both safety and efficiency in your welding operations. Always prioritize proper usage techniques and regular inspection to ensure maximum protection.