Welding Safety Blanket: Essential Protection for Sparks and Heat

Summary:A welding safety blanket shields you from sparks, slag, and radiant heat during welding. This guide explains its materials, uses, and how to choose the right one for maximum safety.

Why You Need a Welding Safety Blanket

Welding produces extreme heat, sparks, and molten metal that can damage nearby surfaces or cause fires. A welding safety blanketacts as a barrier, protecting floors, equipment, and flammable materials. Made from fire-resistant materials like fiberglass or silica, it withstands temperatures up to 2,000°F (1,093°C). Always place it under your work area to catch falling debris.

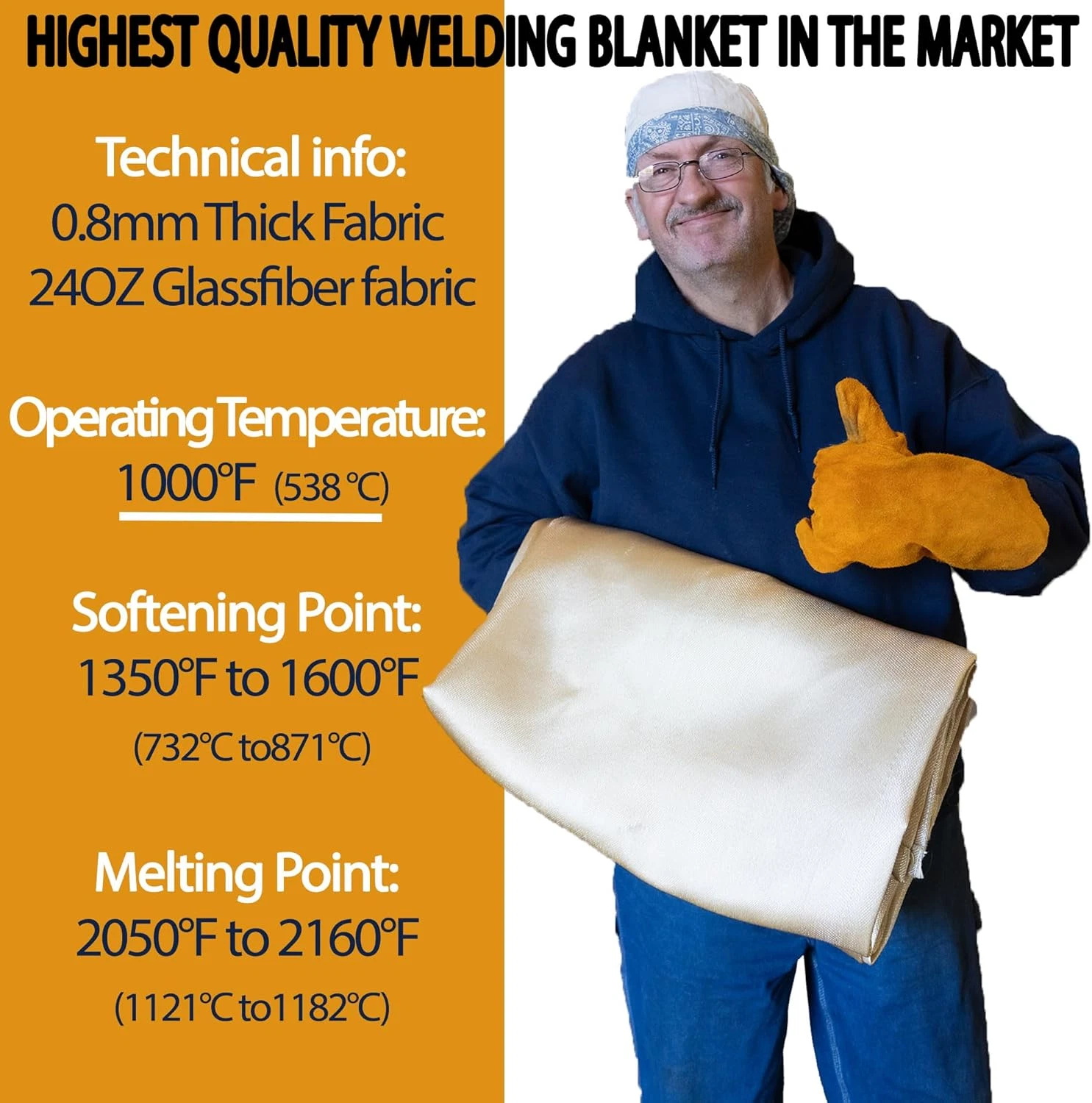

Key Features of a Quality Welding Safety Blanket

1. Material:Fiberglass is common, but silica blankets offer higher heat resistance.2. Thickness:1/8" to 1/4" thick blankets provide durability.3. Size:Choose 4'x6' for small projects or 6'x8' for larger areas.4. Flexibility:Foldable blankets are easier to store and transport.

How to Use a Welding Safety Blanket Correctly

- Lay the blanket flat, ensuring full coverage under your welding zone.- Overlap multiple blankets if your workspace is large.- Secure edges with weights or clamps to prevent shifting.- Inspect for tears before each use—replace damaged blankets immediately.

Welding Safety Blanket vs. Other Protective Gear

Unlike welding curtains (for UV protection) or aprons (for personal safety), a welding safety blanketfocuses on surface protection. Combine it with gloves, helmets, and proper ventilation for complete safety. For overhead welding, consider adding a fire-resistant tarp.

Maintenance and Storage Tips

- Shake off slag and debris after use.- Store in a dry place to prevent moisture damage.- Hand wash with mild soap if heavily soiled; avoid harsh chemicals.- Replace blankets that show signs of brittleness or thinning.

Common Mistakes to Avoid

1. Using blankets with visible holes.2. Placing blankets too close to the weld pool (maintain 2-3 feet distance).3. Ignoring local fire safety regulations about combustible materials.

Choosing the Right Blanket for Your Project

For MIG/TIG welding, standard fiberglass blankets work well. For plasma cuttingor oxy-fuel welding, opt for silica-based blankets with higher temperature ratings. Always check the manufacturer's specifications for your specific welding process.

Where to Buy Reliable Welding Safety Blankets

Purchase from reputable safety equipment suppliers or welding specialty stores. Look for certifications like OSHA compliance or ASTM standards. Online retailers often provide detailed product descriptions and customer reviews to help you compare options.

Final Safety Reminders

A welding safety blanketis just one part of your protection system. Always wear appropriate PPE, maintain a clean workspace, and keep a fire extinguisher nearby. Regularly train your team on proper blanket usage to prevent accidents.