6'x15' Welding Fire Blanket - Ultimate Protection for Hot Work Safety

This guide explains why a 6'x15' welding fire blanket is essential for industrial safety. You'll learn its proper uses, material advantages, and how it outperforms smaller blankets in protecting against sparks and molten metal during welding operations.

Why Choose a 6'x15' Fire Blanket for Welding?

When you're working with welding torches or grinders, standard 4'x4' fire blankets won't provide adequate coverage. The fire blanket 6'x15 for weldingoffers extended protection for larger work areas. Its rectangular shape perfectly covers welding tables, protects walls behind workstations, and can even be draped over machinery.

Unlike smaller blankets, this size allows you to:

- Create complete barriers around welding zones

- Protect multiple workers simultaneously

- Cover irregularly shaped equipment

- Handle larger spark showers from industrial welding

Superior Materials for Extreme Heat

The best 6'x15 welding fire blanketsuse fiberglass with silicone coating, rated for continuous exposure to 1000°F (538°C) and brief contact up to 1800°F (982°C). This makes them ideal for:

- MIG/TIG welding applications

- Plasma cutting operations

- Thermal spray processes

- Foundry work near combustible materials

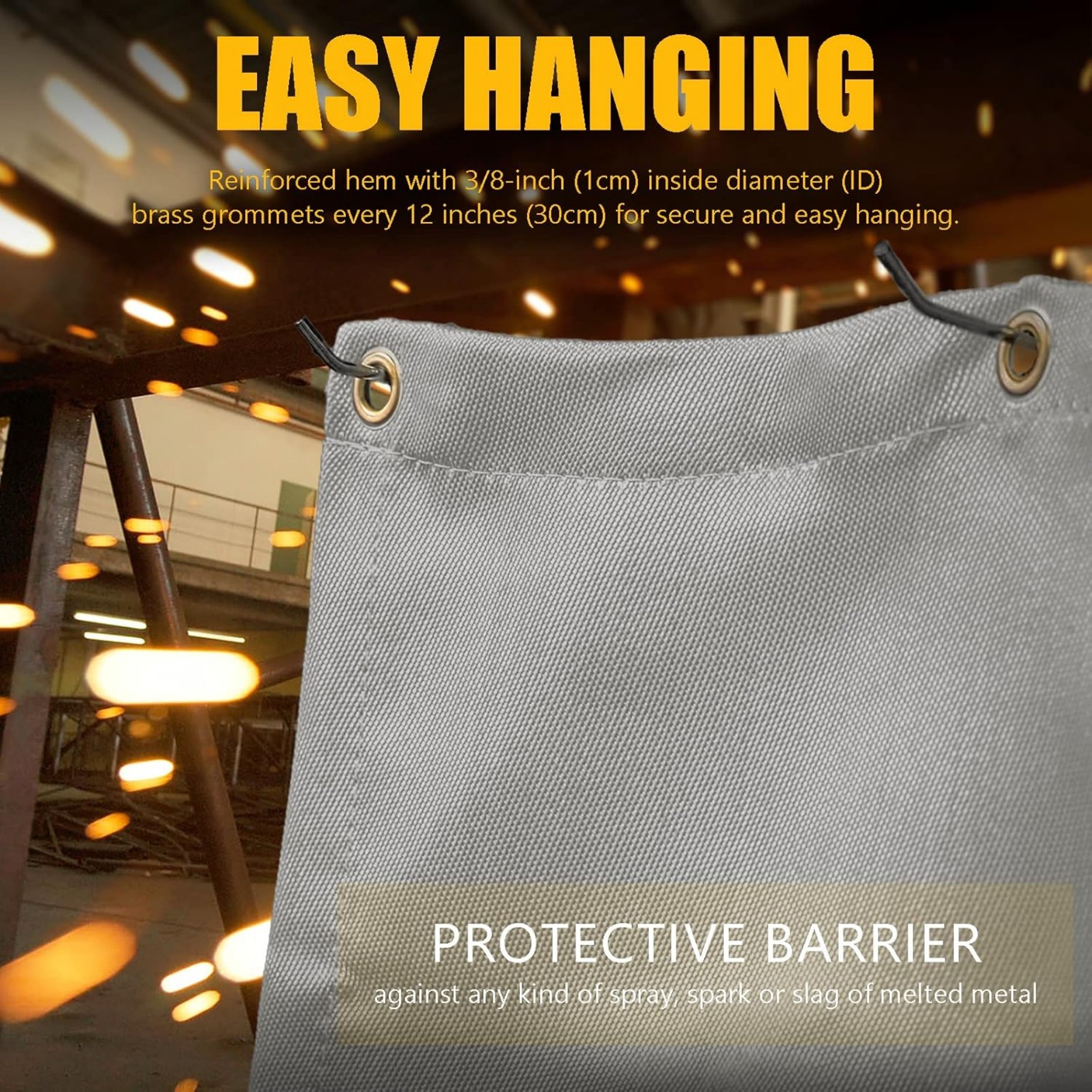

Look for blankets with reinforced grommets at the corners - these allow secure mounting in permanent installations while maintaining quick-release functionality for emergency use.

Proper Installation Techniques

To maximize your fire blanket 6'x15 for weldingeffectiveness:

- Vertical mounting:Hang 12-18 inches behind welding areas using fire-resistant hooks

- Table coverage:Drape over work tables with at least 6" overhang on all sides

- Floor protection:Layer under grinding stations to catch falling embers

- Equipment wrapping:Secure around gas cylinders or hoses near hot work

Remember to overlap multiple blankets by at least 6 inches when covering large areas. Never stretch the blanket tight - leave some slack to absorb impact from flying debris.

Maintenance and Inspection

Your 6'x15' welding fire blanketrequires regular care:

- Inspect weekly for holes or thinning areas

- Clean with compressed air (never water or chemicals)

- Replace immediately if silicone coating flakes off

- Store flat or rolled - never folded (to prevent crease damage)

Professional welding shops should maintain at least one spare blanket per work area. The large size means quicker coverage during emergencies compared to piecing together smaller blankets.

Comparing to Alternative Protection Methods

While metal shields and cement boards have their place, the fire blanket 6'x15 for weldingoffers unique advantages:

| Protection Method | Advantages | Disadvantages |

|---|---|---|

| 6'x15' Fire Blanket | Flexible, reusable, lightweight, full coverage | Requires proper storage |

| Metal Welding Curtains | Durable | Heavy, limited mobility, conducts heat |

| Spray-on Fire Retardants | Permanent coating | Not reusable, requires reapplication |

Emergency Use Protocol

In case of fire, your 6'x15 welding fire blanketcan smother flames:

- Pull blanket from its container using the corner tabs

- Hold the blanket like a shield between you and the fire

- Place gently over flames - never throw (this fans the fire)

- Leave in place until area completely cools (minimum 30 minutes)

Note: These large blankets require two people for proper emergency deployment. Conduct quarterly training drills to ensure all workers know handling techniques.

Industry Standards Compliance

Quality fire blanket 6'x15 for weldingproducts meet:

- NFPA 51B (Standard for Fire Prevention During Welding)

- OSHA 1910.252 (Hot Work Safety Regulations)

- ASTM F1989 (Standard Specification for Fire Blankets)

Always verify certification labels before purchase. Industrial-grade blankets will have permanently marked ratings rather than paper tags that can burn off.

Cost vs. Value Analysis

While a 6'x15' welding fire blanketcosts more initially than smaller options, it provides greater value:

- Longer lifespan:The larger size means less frequent replacement

- Reduced labor:Covers more area with single deployment

- Insurance benefits:Many providers offer premium discounts for proper hot work protection

For most fabrication shops, the blanket pays for itself within 6 months through prevented damage and compliance savings.

Where to Purchase Quality Blankets

When buying your fire blanket 6'x15 for welding, look for:

- US-made products (consistent quality control)

- Suppliers specializing in welding safety

- Blankets with manufacturer warranties

- Bulk purchase discounts for multiple workstations

Avoid generic "fire blankets" - welding-specific models have tighter weave patterns and higher temperature ratings.