Heavy Welding Blanket Guide: Protection, Uses & Safety Tips

This guide explains how heavy welding blankets protect against sparks, heat, and molten metal. You'll learn about materials, applications, safety benefits, and proper maintenance for optimal performance.

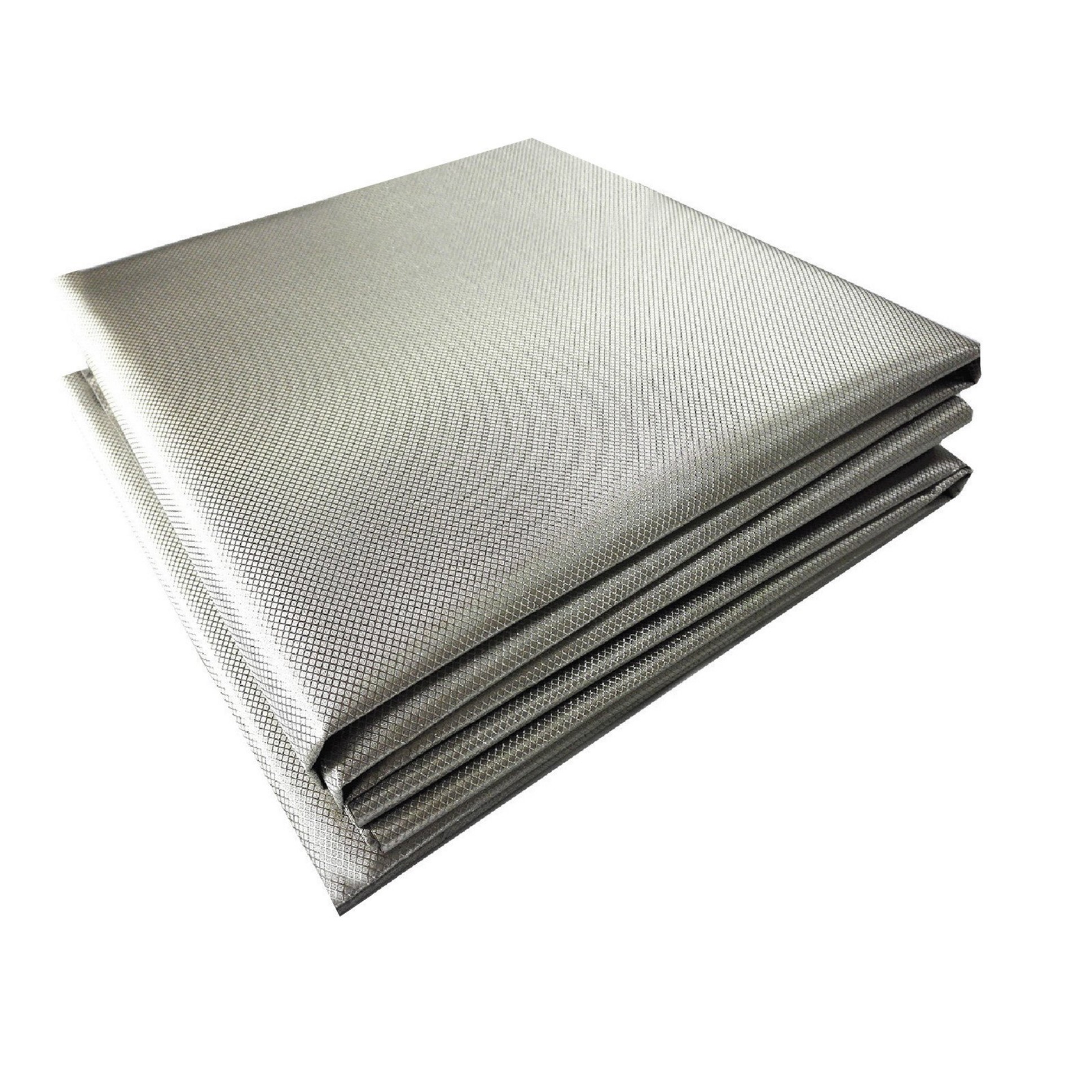

What Is a Heavy Welding Blanket?

A heavy welding blanket is a specialized protective covering designed to withstand extreme heat and sparks from welding operations. Unlike regular blankets, these industrial-grade barriers use multiple layers of heat-resistant materials to protect workers, equipment, and surrounding areas.

Key Materials in Heavy Welding Blankets

Quality heavy welding blankets typically combine these materials:

- Fiberglass:The most common base material, offering excellent heat resistance up to 1,000°F (538°C)

- Silica fabric:For higher temperature applications (up to 2,000°F/1,093°C)

- Vermiculite coating:Adds extra spark and slag protection

- Reinforced edges:Metal grommets or stitching for durability

When to Use Heavy Welding Blankets

You should always use a heavy welding blanket in these situations:

- Overhead welding where sparks might fall on equipment or personnel

- Confined spaces where heat could damage nearby surfaces

- Multi-welder operations creating concentrated heat zones

- Temporary containment of hot work in maintenance areas

Safety Benefits You Can't Ignore

A proper heavy welding blanket provides three critical safety functions:

- Fire prevention:Stops sparks from igniting flammable materials

- Heat shielding:Protects sensitive equipment from radiant heat

- Molten metal containment:Catches dripping slag during vertical welds

Choosing the Right Heavy Welding Blanket

Consider these factors when selecting your blanket:

| Factor | Consideration |

|---|---|

| Temperature rating | Match to your welding process (MIG/TIG/stick produces different heat) |

| Size | Coverage should exceed work area by at least 2 feet on all sides |

| Weight | Heavier blankets (8-10 oz/sq ft) offer better protection than lighter ones |

| Flexibility | Some applications need draping capability while others require rigidity |

Proper Maintenance for Longevity

Follow these care tips to extend your heavy welding blanket's life:

- Shake off slag and debris after each use

- Store flat or rolled (never folded) to prevent material fatigue

- Inspect regularly for holes or thinning areas

- Wash only when necessary using mild detergent and air dry

Common Mistakes to Avoid

Even experienced welders sometimes make these errors with heavy welding blankets:

- Using the same blanket for cutting and welding (different heat profiles)

- Placing blankets directly against combustible surfaces

- Ignoring manufacturer's temperature limits

- Reusing blankets with significant damage

Alternatives to Consider

While heavy welding blankets work for most applications, you might need:

- Welding curtains:For visibility needs in open areas

- Custom shields:When standard sizes don't fit unique equipment

- Multi-layer systems:For extreme temperature applications

Final Safety Reminder

Remember that no heavy welding blanket makes welding completely safe. Always combine blanket use with proper PPE (helmet, gloves, jacket) and follow all standard welding safety protocols in your work area.