Welding Blanket Smoker Insulation: DIY Heat Retention Guide

Summary:Welding blanket smoker insulation helps maintain consistent temperatures in your smoker. This guide explains how to choose, install, and safely use welding blankets for better heat retention while smoking meats.

Why Use Welding Blankets for Smoker Insulation?

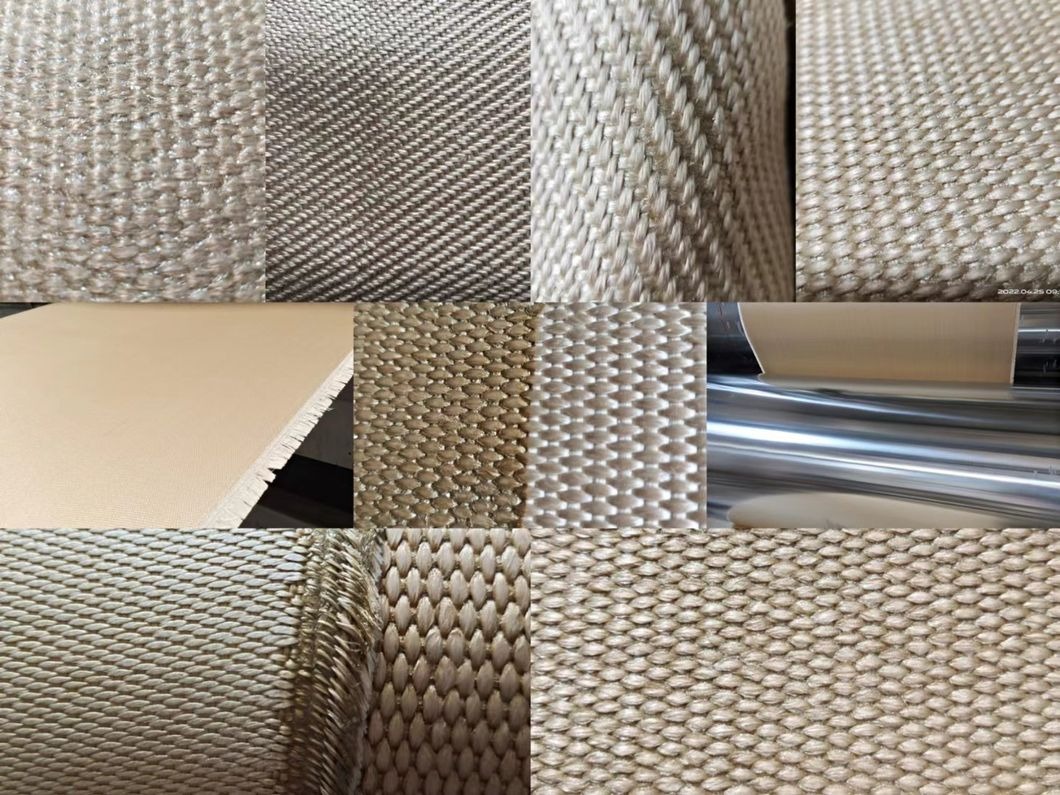

When you're smoking meats for hours, temperature control matters. Welding blankets provide affordable, effective insulation for your smoker. Made from fiberglass or silica fabric, these blankets withstand extreme heat (up to 2000°F) while being flexible enough to wrap around smokers of various shapes.

Unlike specialized smoker jackets, welding blanket smoker insulation costs less and works with any smoker model. The dense fiberglass layers trap heat inside, reducing fuel consumption and maintaining steady cooking temperatures even in cold weather.

Choosing the Right Welding Blanket

Not all welding blankets work equally well for smoker insulation. Look for these features:

- Temperature rating:Minimum 1000°F capacity (higher is better)

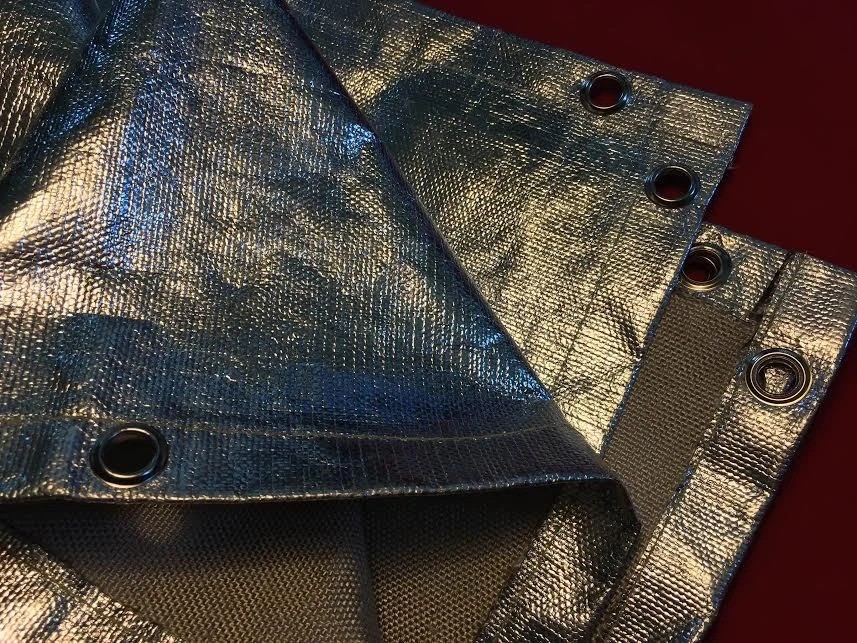

- Material:Fiberglass with silicone coating resists moisture

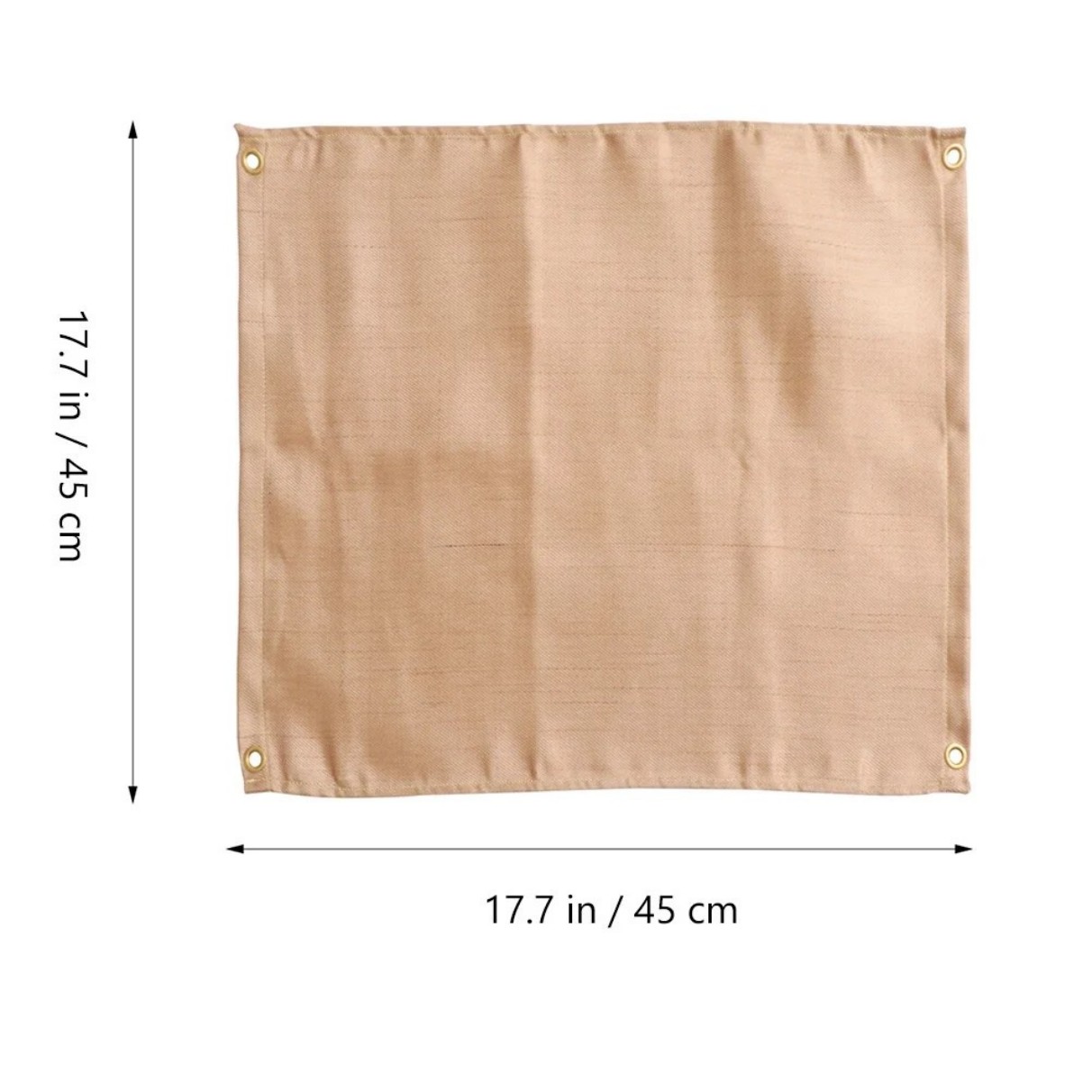

- Thickness:1/8" to 1/4" provides optimal insulation

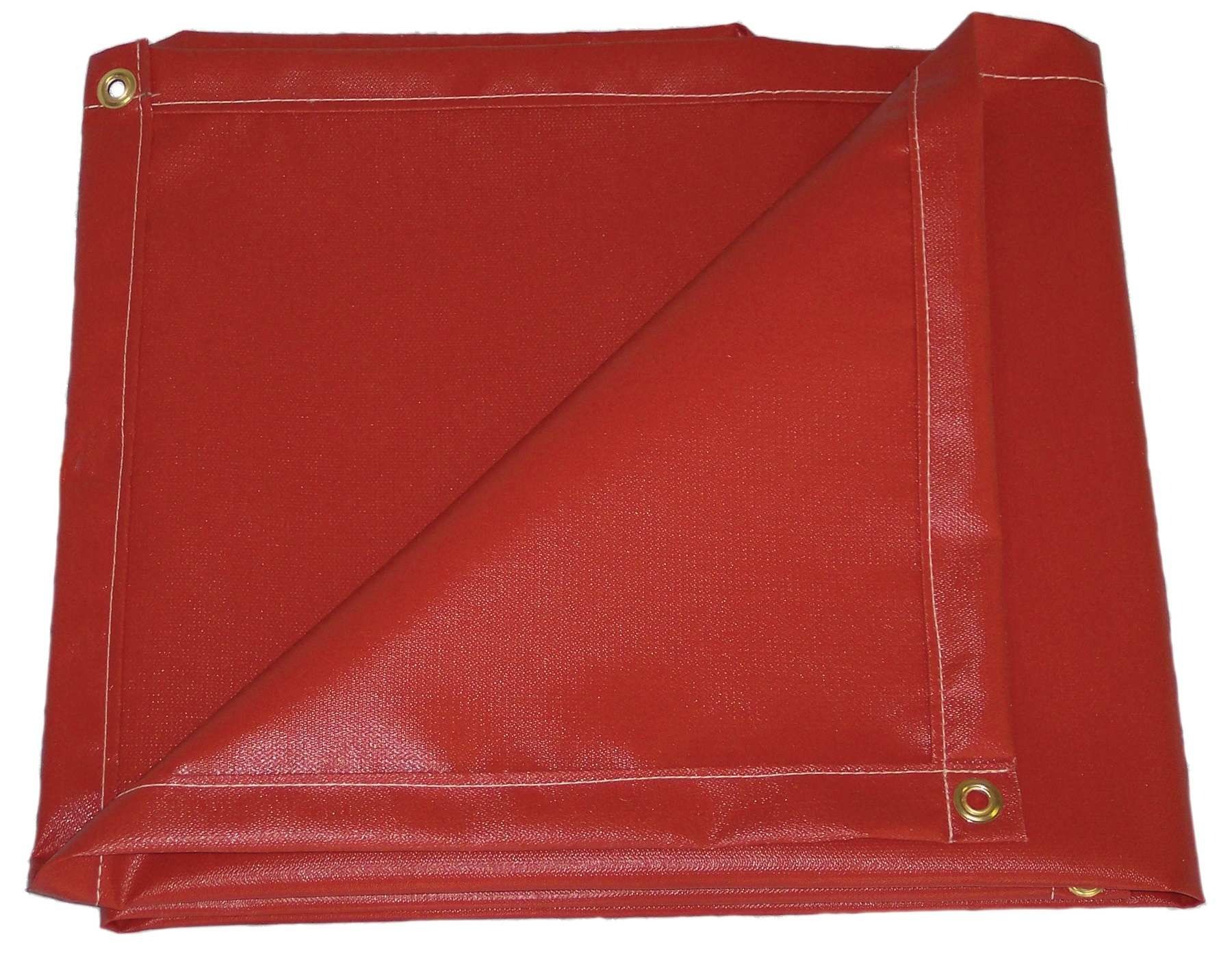

- Size:Measure your smoker first - blankets typically come in 4'x6' or 6'8" sizes

Avoid blankets with loose fibers that could shed into your food. The best welding blanket smoker insulation has tightly woven fibers and reinforced edges.

How to Install Welding Blanket Insulation

Follow these steps for safe, effective installation:

- Clean your smoker's exterior surface

- Measure and cut the blanket to fit (leave openings for vents/dampers)

- Secure with stainless steel clamps or high-temp zip ties

- For permanent installation, use high-temperature silicone adhesive

- Add reflective foil facing outward for extra heat reflection

Never let the welding blanket contact hot surfaces directly - maintain at least 1" air gap. Check periodically for wear or fiber shedding.

Safety Considerations

While welding blanket smoker insulation works well, observe these precautions:

- Wear gloves when handling - fiberglass can irritate skin

- Work in a ventilated area when cutting

- Keep blankets dry - moisture reduces effectiveness

- Inspect regularly for damage

- Never use damaged or frayed blankets

The blanket shouldn't interfere with your smoker's airflow or safety features. Maintain clear access to all controls and vents.

Performance Benefits

Properly installed welding blanket smoker insulation delivers measurable improvements:

- 25-40% reduction in fuel consumption

- More stable cooking temperatures (±5°F vs ±25°F without insulation)

- Faster recovery after opening the smoker

- Ability to smoke in colder weather

- Extended smoker lifespan by reducing thermal cycling stress

For best results, combine with other heat retention methods like water pans and thermal gaskets.

Maintenance Tips

To keep your welding blanket smoker insulation effective:

- Brush off ash and debris after each use

- Store indoors when not in use

- Check for compression or matting of fibers

- Replace if you notice significant fiber loss

- Consider having a spare blanket for long smoking sessions

With proper care, quality welding blanket insulation can last 2-3 smoking seasons before needing replacement.

Alternative Uses for Smoking

Beyond smoker insulation, welding blankets serve other BBQ purposes:

- Wind break for outdoor cooking

- Emergency grill cover

- Heat shield for nearby surfaces

- Cold weather cooking aid

Their versatility makes welding blankets valuable additions to any serious pitmaster's toolkit.