Welding Felt Carbon Fiber Blanket: Heat Protection for Industrial Applications

Summary:A welding felt carbon fiber blanket is a high-temperature resistant material used to protect surfaces from sparks, slag, and heat during welding. It's durable, flexible, and essential for safety in metalworking.

What Is a Welding Felt Carbon Fiber Blanket?

When you work with welding or metal fabrication, heat protection is critical. A welding felt carbon fiber blanket is designed to shield floors, equipment, and workers from extreme temperatures. Made from carbon fiber felt layered with heat-resistant materials, it can withstand temperatures up to 2000°F (1093°C). Unlike traditional fiberglass blankets, it offers better durability and flexibility.

Key Benefits of Using a Welding Felt Carbon Fiber Blanket

Why should you choose this type of blanket for your workshop? Here are the top advantages:

- Extreme Heat Resistance:It doesn’t melt or degrade under high heat, making it ideal for welding, foundries, and furnace work.

- Lightweight & Flexible:Easy to drape over uneven surfaces or wrap around pipes.

- Reusable:Unlike disposable covers, it can be used repeatedly without losing effectiveness.

- Non-Conductive:Safe for electrical insulation in high-heat environments.

Where Can You Use a Welding Felt Carbon Fiber Blanket?

This versatile material is useful in multiple industries:

- Welding & Metal Fabrication:Protects floors and nearby materials from sparks.

- Automotive:Shields sensitive components during exhaust system repairs.

- Aerospace:Used in thermal insulation for aircraft components.

- Foundries:Covers molten metal containers to prevent heat loss.

How to Choose the Right Welding Felt Carbon Fiber Blanket

Not all blankets are the same. Consider these factors before buying:

- Temperature Rating:Ensure it matches your maximum working temperature.

- Thickness:Thicker blankets offer better protection but may be less flexible.

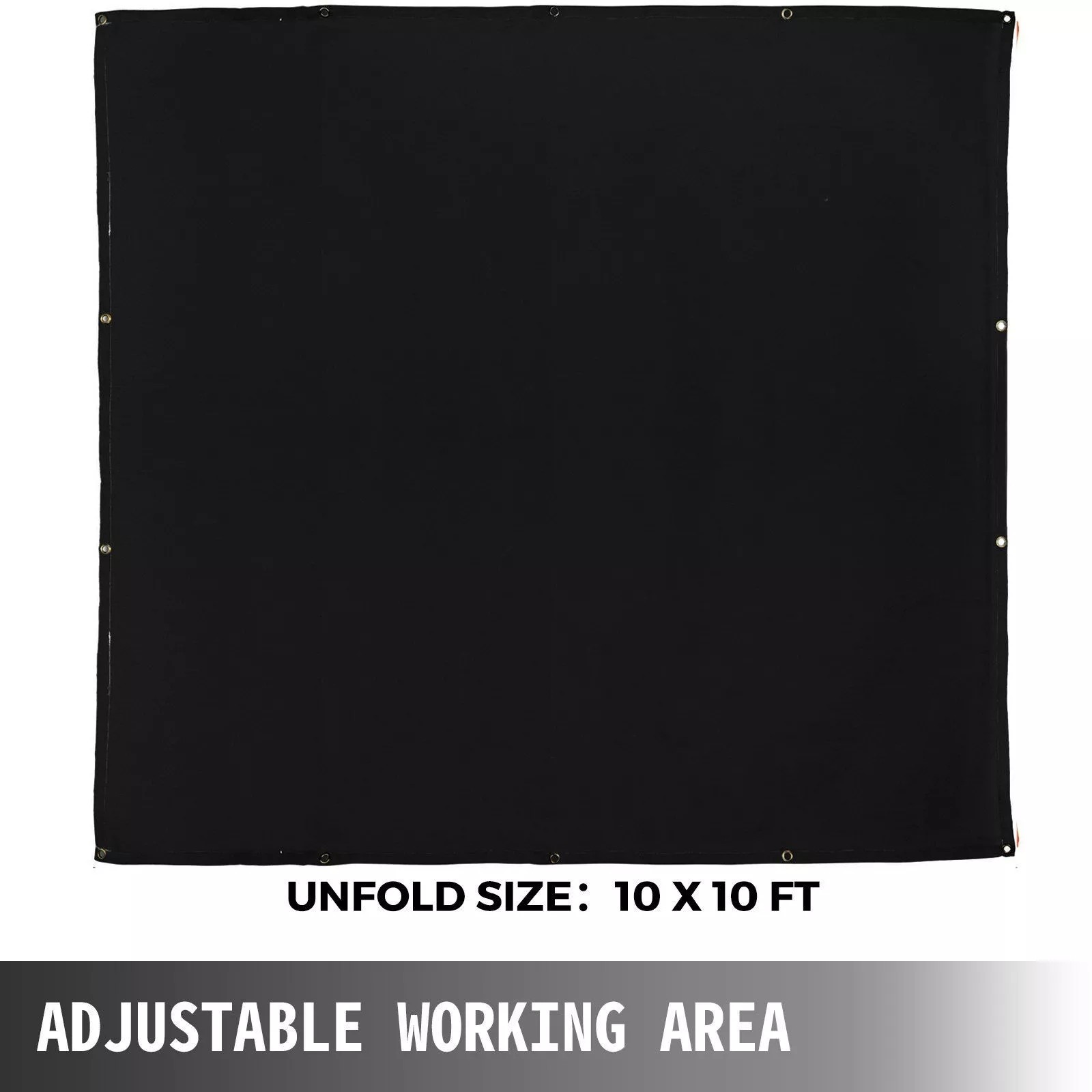

- Size:Pick a size that covers your work area sufficiently.

- Certifications:Look for OSHA or ASTM compliance for workplace safety.

Maintenance Tips for Longevity

To keep your welding felt carbon fiber blanket in top condition:

- Store it flat or rolled, not folded, to prevent creases.

- Clean off slag and debris after each use.

- Avoid sharp objects that could tear the fibers.

- Inspect regularly for wear and replace if damaged.

Conclusion

A welding felt carbon fiber blanket is a must-have for anyone working with high heat. It provides reliable protection, lasts long, and improves workplace safety. Choose the right one for your needs and maintain it properly to get the best performance.