Welding Blanket vs Fire Blanket: Key Differences and Uses

Welding blankets and fire blankets serve different safety purposes. While both protect against heat, welding blankets handle intense, localized heat from welding, whereas fire blankets smother small fires. This guide explains their differences, materials, and proper applications.

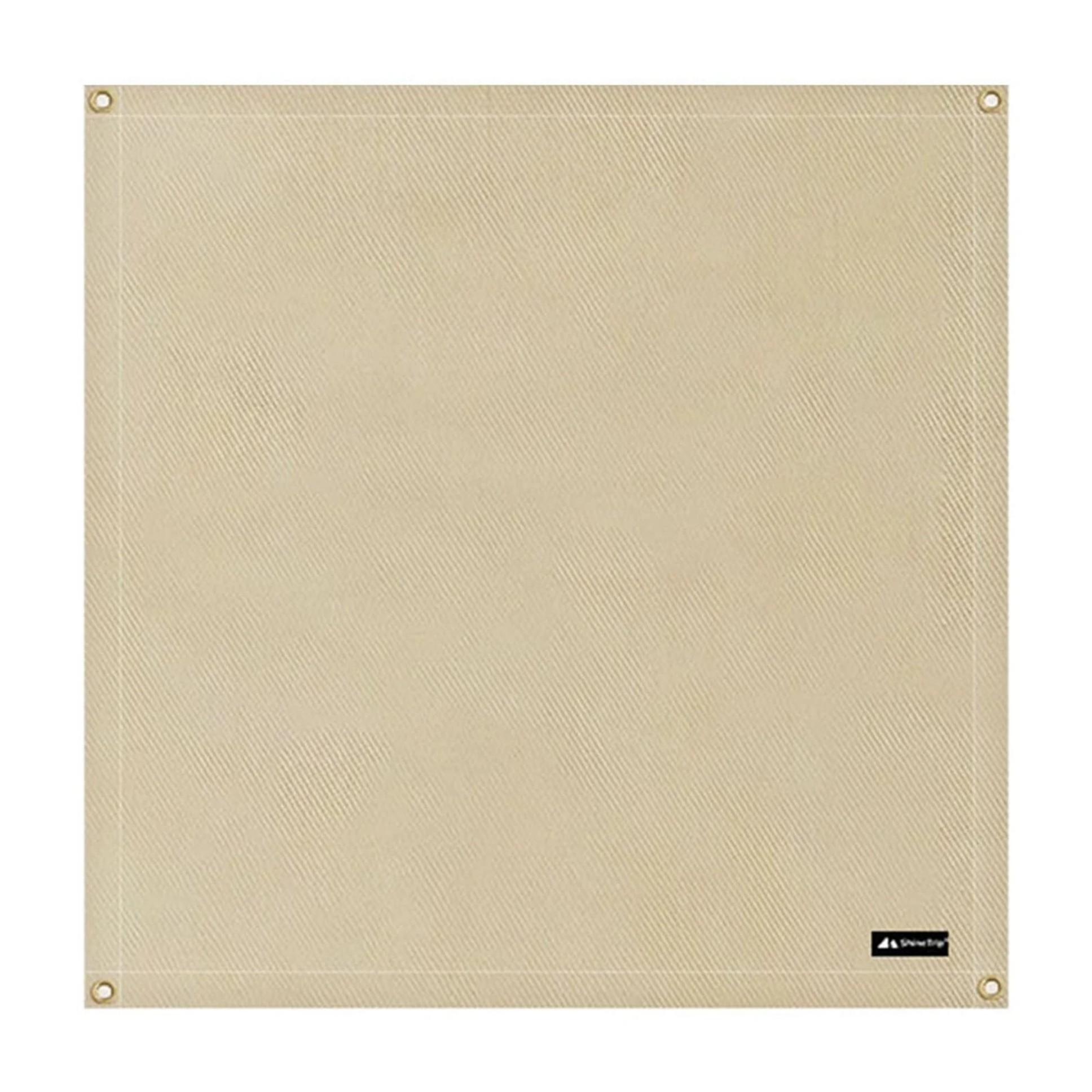

What is a Welding Blanket?

A welding blanket is a heat-resistant safety device designed specifically to protect against sparks, slag, and molten metal during welding operations. These blankets are made from materials like fiberglass, silica, or ceramic fibers that can withstand extremely high temperatures (typically 1,800°F to 3,000°F).

Key features of welding blankets:

- Made from multiple layers of heat-resistant fabric

- Designed to resist direct flame contact

- Available in various sizes for different welding applications

- Often treated with coatings to repel molten metal

- Typically heavier and more rigid than fire blankets

What is a Fire Blanket?

A fire blanket is a safety device used to extinguish small fires by cutting off oxygen supply. These are commonly found in kitchens, laboratories, and workshops. Fire blankets are usually made from fiberglass or wool treated with fire-retardant chemicals.

Key features of fire blankets:

- Lighter and more flexible than welding blankets

- Designed for rapid deployment in emergency situations

- Effective on small grease fires, electrical fires, and clothing fires

- Typically rated for temperatures up to 900°F

- Often stored in easy-to-access wall-mounted containers

Welding Blanket vs Fire Blanket: Key Differences

While both products provide heat protection, they serve distinct purposes:

- Temperature resistance:Welding blankets withstand much higher temperatures than fire blankets

- Material thickness:Welding blankets are thicker and heavier

- Primary function:Welding blankets protect surfaces from sparks and molten metal; fire blankets extinguish flames

- Deployment:Fire blankets are designed for quick emergency use; welding blankets are set up before work begins

- Regulations:Fire blankets often must meet specific safety standards (like EN 1869); welding blankets follow different industry standards

When to Use Each Type

Use a welding blanket when:

- Performing welding, cutting, or grinding operations

- Protecting floors, walls, or equipment from sparks and slag

- Working with molten metal or other extremely hot materials

- Need protection from radiant heat during prolonged operations

Use a fire blanket when:

- A small fire breaks out (especially grease or clothing fires)

- You need to smother flames quickly

- Electrical equipment catches fire (when it's safe to approach)

- As personal protection when escaping through flames

Safety Considerations

Never use a fire blanket in place of a welding blanket - it won't provide adequate protection against welding sparks and could melt. Similarly, welding blankets aren't designed for emergency fire suppression. Always choose the right tool for your specific needs.

For both types:

- Inspect regularly for damage or contamination

- Follow manufacturer's instructions for use and maintenance

- Replace if damaged or after single use (for fire blankets)

- Store properly to prevent degradation

Conclusion

Understanding the difference between welding blankets and fire blankets is crucial for workplace safety. Welding blankets protect against intense, localized heat during metalworking, while fire blankets are emergency devices for smothering small fires. Always use the appropriate blanket for your specific situation to ensure maximum protection.