How Welding Preheat Blankets Improve Joint Quality and Safety

Summary:Welding preheat blankets maintain optimal metal temperatures before, during, and after welding. They prevent cracking, reduce residual stress, and ensure proper fusion. This guide explains their benefits, types, and proper usage for superior weld quality.

Why You Need a Welding Preheat Blanket

When you weld thick materials or alloys like carbon steel, the temperature difference between the weld zone and base metal causes stress. A welding preheat blanket maintains consistent temperatures around the joint area. This prevents three major problems:

- Cracking:Sudden cooling creates brittle zones that crack

- Poor fusion:Cold base metal doesn't bond properly with filler material

- Distortion:Uneven heating warps the workpiece

How Welding Preheat Blankets Work

These flexible electric blankets wrap around pipes, beams, or plates. You set the temperature (typically 150-400°F/65-200°C) based on:

- Material thickness (thicker = more preheat needed)

- Base metal type (carbon steel requires more than stainless)

- Ambient temperature (cold environments need extra heating)

Modern welding preheat blankets use ceramic fiber insulation and Kanthal heating elements that withstand direct flame contact. Digital controllers maintain ±5°F accuracy.

Choosing the Right Welding Preheat Blanket

Consider these four factors when selecting:

| Feature | Option | Best For |

|---|---|---|

| Temperature Range | 200-600°F (95-315°C) | Most carbon steel applications |

| Size | 12"x12" to 48"x96" | Match to joint dimensions |

| Power | 120V or 240V | Worksite electrical capacity |

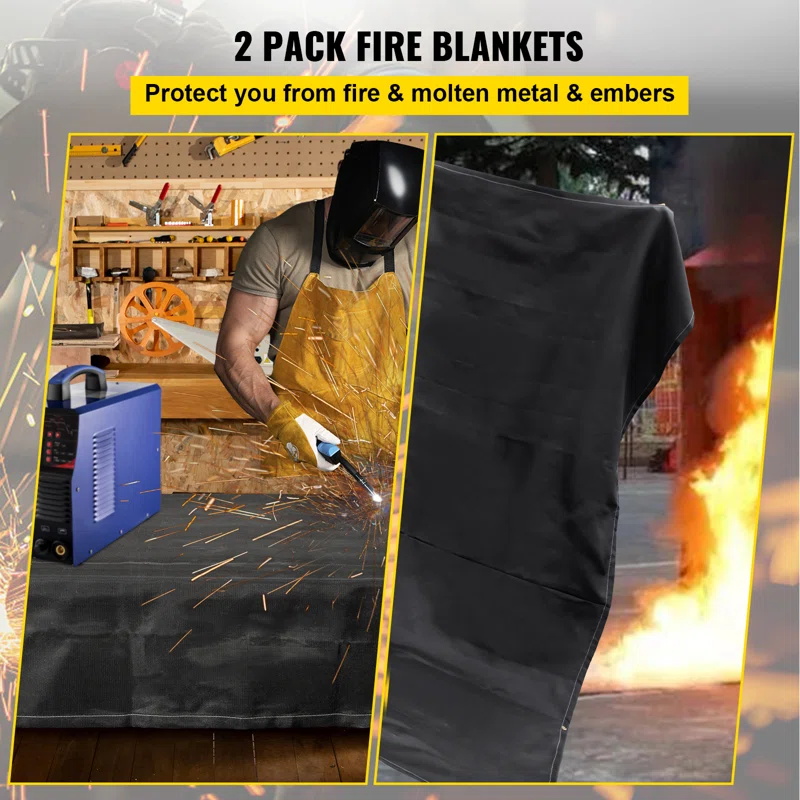

| Material | Silicone or fiberglass | Silicone resists sparks better |

Proper Use of Welding Preheat Blankets

Follow these steps for effective preheating:

- Clean the joint area thoroughly

- Position the blanket with 2" overlap on all sides of the weld zone

- Secure with straps or magnets (don't use flammable tape)

- Heat at recommended rate (usually 100°F/38°C per hour)

- Verify temperature with a contact pyrometer

- Maintain heat during welding and cool slowly (50-100°F/10-38°C per hour)

Advanced Applications

Beyond standard preheating, welding preheat blankets help with:

- Post-weld heat treatment (PWHT):Stress relief at 1100-1250°F (595-675°C)

- Hydrogen bake-out:Removing diffusible hydrogen that causes cracking

- Pipeline welding:Maintaining heat during stops in critical passes

Safety Considerations

While welding preheat blankets are safe when used properly:

- Never exceed the maximum rated temperature

- Inspect for damage to heating elements or insulation

- Keep flammable materials at least 3 feet away

- Use GFCI-protected power sources

- Allow proper cooling before storage

Cost vs. Benefits

A quality welding preheat blanket costs $300-$2000, but prevents:

- Rework from failed welds ($500-$5000 per incident)

- Equipment damage from stress fractures

- Safety incidents from sudden failures

- Project delays from improper procedures

For code-compliant welding on thick materials, preheat blankets aren't optional - they're essential equipment that pays for itself quickly.