Heat Resistant Welding Blankets: Essential Protection for Safe Welding

Summary:Heat resistant welding blankets protect workers and surfaces from sparks, slag, and extreme heat during welding. This guide explains their materials, benefits, and proper use for maximum safety and efficiency.

What Are Heat Resistant Welding Blankets?

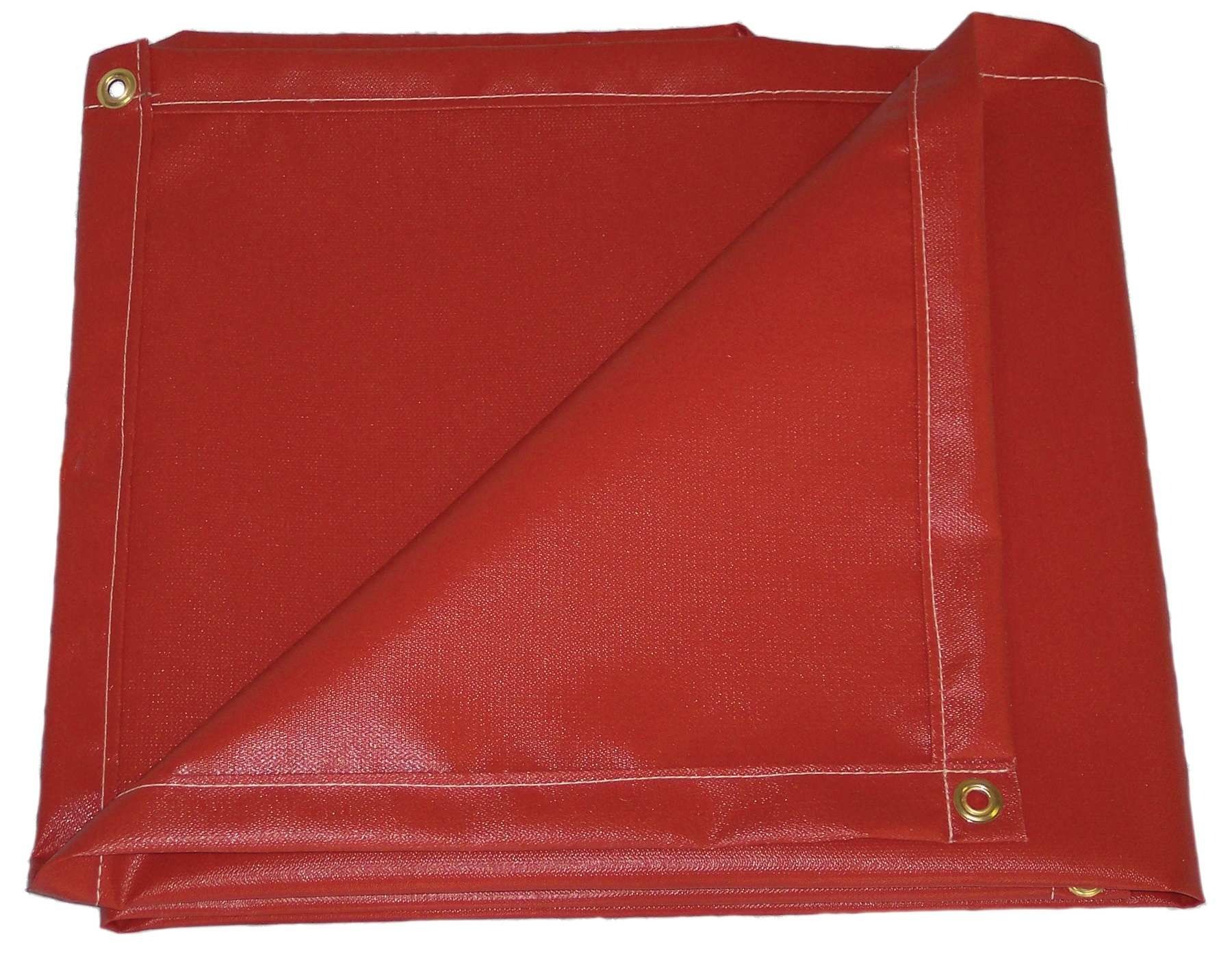

Heat resistant welding blankets are specialized protective covers made from fireproof materials. You use them to shield surrounding areas from welding hazards. These blankets withstand temperatures up to 3000°F (1650°C) while remaining flexible and durable.

Key Materials in Quality Welding Blankets

The best heat resistant welding blankets typically use:

- Fiberglass:Most common, affordable, and resistant to 1000°F (540°C)

- Silica:Handles up to 1800°F (980°C) with excellent flexibility

- Carbon Fiber:Ultra-high resistance to 3000°F (1650°C)

- Ceramic Fiber:Lightweight option for extreme heat applications

Why You Need Heat Resistant Welding Blankets

These blankets provide three critical protections:

- Fire Prevention:Stops sparks from igniting nearby materials

- Surface Protection:Prevents heat damage to floors and equipment

- Safety Compliance:Meets OSHA and workplace safety standards

Choosing the Right Welding Blanket

Consider these factors when selecting heat resistant welding blankets:

- Temperature Rating:Match to your welding process (MIG, TIG, or arc)

- Size:Cover at least 3 feet beyond your work area

- Weight:Heavier blankets offer better spark resistance

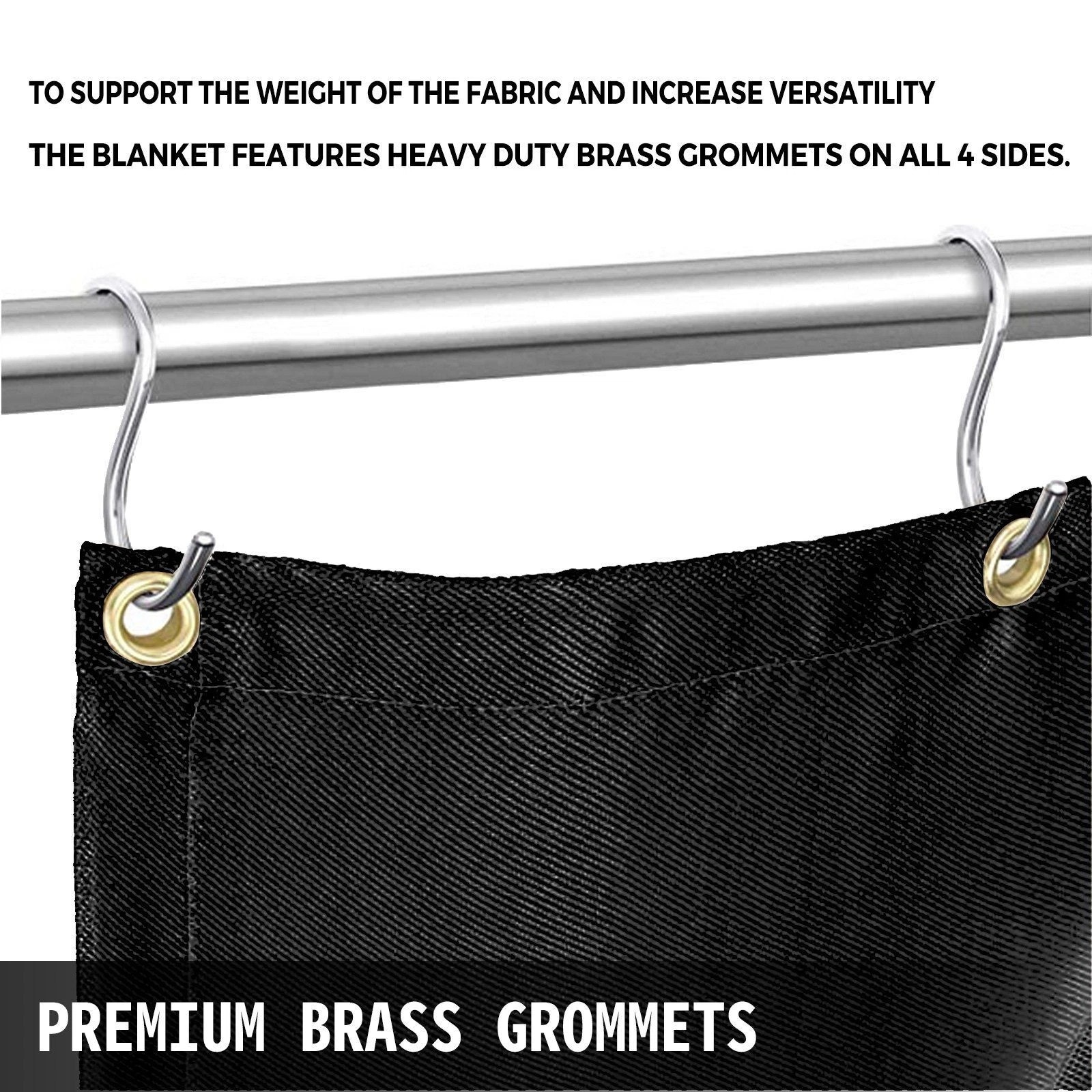

- Edge Treatment:Look for reinforced grommets for hanging

Proper Use and Maintenance

To maximize your heat resistant welding blanket's lifespan:

- Inspect for damage before each use

- Clean with compressed air, never water

- Store flat or rolled, never folded

- Replace when fibers become brittle or discolored

Specialized Welding Blanket Applications

Beyond standard welding, these blankets work for:

- Foundry work and metal casting

- Fireplace and chimney maintenance

- Automotive exhaust system repairs

- Industrial furnace maintenance

Safety Tips When Using Welding Blankets

Remember these precautions:

- Always wear proper PPE beneath the blanket

- Never use damaged or wet blankets

- Keep flammable materials at least 35 feet away

- Allow blankets to cool completely before moving

Comparing Welding Blankets to Other Protection Methods

While alternatives exist, heat resistant welding blankets offer unique advantages:

| Protection Method | Pros | Cons |

|---|---|---|

| Welding Blankets | Portable, reusable, multi-surface protection | Requires proper storage |

| Metal Screens | Durable, good visibility | Heavy, doesn't catch falling slag |

| Spray Barriers | Conforms to odd shapes | Single-use, messy application |

Innovations in Welding Blanket Technology

Recent advancements include:

- Multi-layer composites for higher protection

- Reflective coatings to reduce radiant heat

- Anti-static treatments for explosive environments

- Custom-cut shapes for specific applications

Conclusion

Heat resistant welding blankets are essential safety tools for any welding operation. By choosing the right material and size, using proper techniques, and maintaining your blanket correctly, you ensure maximum protection and value. Always prioritize quality when selecting these critical safety items.