Top Welding Blankets Manufacturer - Fire-Resistant Safety Solutions

This guide explains what welding blankets do, how to choose a reliable welding blankets manufacturer, and key features to look for in quality fire-resistant protection for industrial and DIY applications.

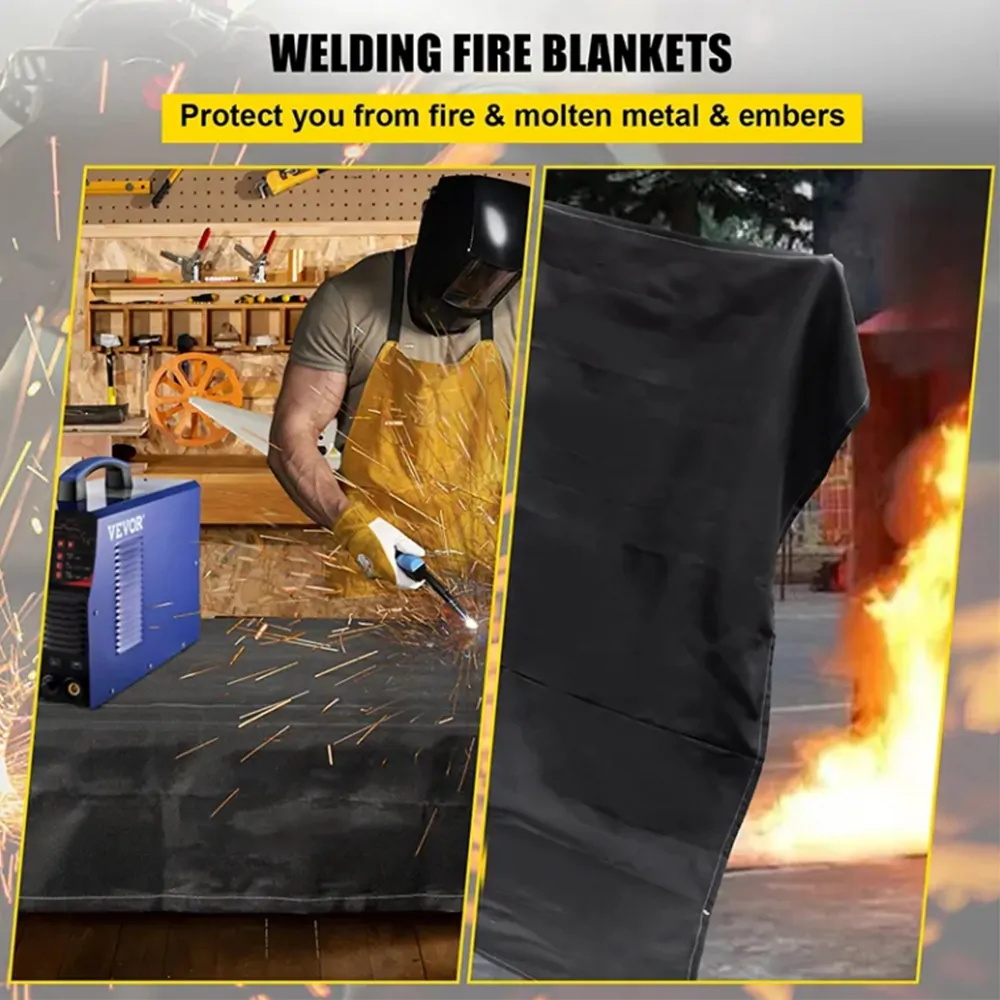

What Are Welding Blankets and Why You Need Them

Welding blankets are essential safety tools that protect workers and surfaces from sparks, heat, and molten metal during welding operations. A professional welding blankets manufacturer produces these protective covers using specialized fire-resistant materials that can withstand extreme temperatures up to 3000°F (1650°C).

When you're working with welding equipment, these blankets serve multiple purposes:

- Protect floors and walls from heat damage

- Prevent fire hazards from flying sparks

- Shield nearby equipment and materials

- Create safe work zones in confined spaces

How to Choose a Reliable Welding Blankets Manufacturer

Selecting the right welding blankets manufacturer ensures you get durable, certified protection. Consider these factors:

Material Quality

Top manufacturers use fiberglass, silica, or ceramic fabrics with proper heat-resistant coatings. Ask about the exact temperature rating and durability tests.

Certifications

Look for ISO 9001 certification and compliance with OSHA 1910.252 standards. Reputable manufacturers will provide test reports.

Customization Options

Good manufacturers offer various sizes (typically 4'x6' to 12'x12'), thicknesses (1/16" to 1/8"), and can add grommets or reinforced edges.

Industry Experience

Choose a manufacturer with at least 5-10 years in the welding safety business who understands different industrial applications.

Key Features of Professional-Grade Welding Blankets

When evaluating products from a welding blankets manufacturer, check for these essential features:

- High temperature resistance:Minimum 1000°F continuous exposure rating

- Flexibility:Should drape easily without cracking

- Chemical resistance:Protection against oils and solvents

- Reinforced edges:Prevents fraying and extends lifespan

- Visibility markings:Bright colors for safety awareness

Maintenance Tips for Your Welding Blankets

Proper care extends the life of your investment from any welding blankets manufacturer:

- Inspect before each use for tears or thin spots

- Clean with compressed air or soft brush - avoid water

- Store flat or rolled (never folded) in dry conditions

- Replace when coating wears off or fabric becomes brittle

Applications Beyond Welding

Quality blankets from a trusted welding blankets manufacturer have multiple uses:

- Foundry work and metal casting

- Fire curtain systems

- High-temperature insulation

- Hot work permits in construction

- Automotive exhaust protection

Finding the Right Manufacturer for Your Needs

Whether you need standard welding blankets or custom solutions, prioritize manufacturers who:

- Offer technical support and product guidance

- Provide samples for evaluation

- Have quick turnaround times

- Maintain consistent quality control

Remember that the cheapest option often costs more in replacements. Invest in quality from an established welding blankets manufacturer to ensure long-term safety and value.