Welding Blanket Pellet Stove: Safety & Efficiency Guide for Home Heating

A welding blanket pellet stove combines efficient heating with enhanced safety. This guide explains proper installation, heat protection, and maintenance tips to maximize performance while preventing fire hazards in your home.

Why Use a Welding Blanket with Your Pellet Stove?

Pellet stoves generate intense heat that can damage nearby walls or flooring. A welding blanket acts as an affordable heat shield, protecting combustible surfaces. Unlike standard insulation, welding blankets withstand temperatures up to 2,000°F (1,093°C) while remaining flexible for custom installations.

Proper Installation Techniques

When installing your welding blanket pellet stove setup:

- Maintain at least 3 inches of air space between the blanket and wall

- Secure with high-temperature fasteners (not standard screws)

- Overlap seams by 6 inches if using multiple blankets

- Never cover vents or air intake areas

Position the blanket to cover at least 18 inches beyond all sides of the stove. For corner installations, use L-shaped configurations.

Material Considerations

Quality welding blankets for pellet stoves typically feature:

- Fiberglass or silica fabric construction

- Vermiculite coating for added insulation

- Reinforced edges to prevent fraying

- Non-asbestos materials meeting OSHA standards

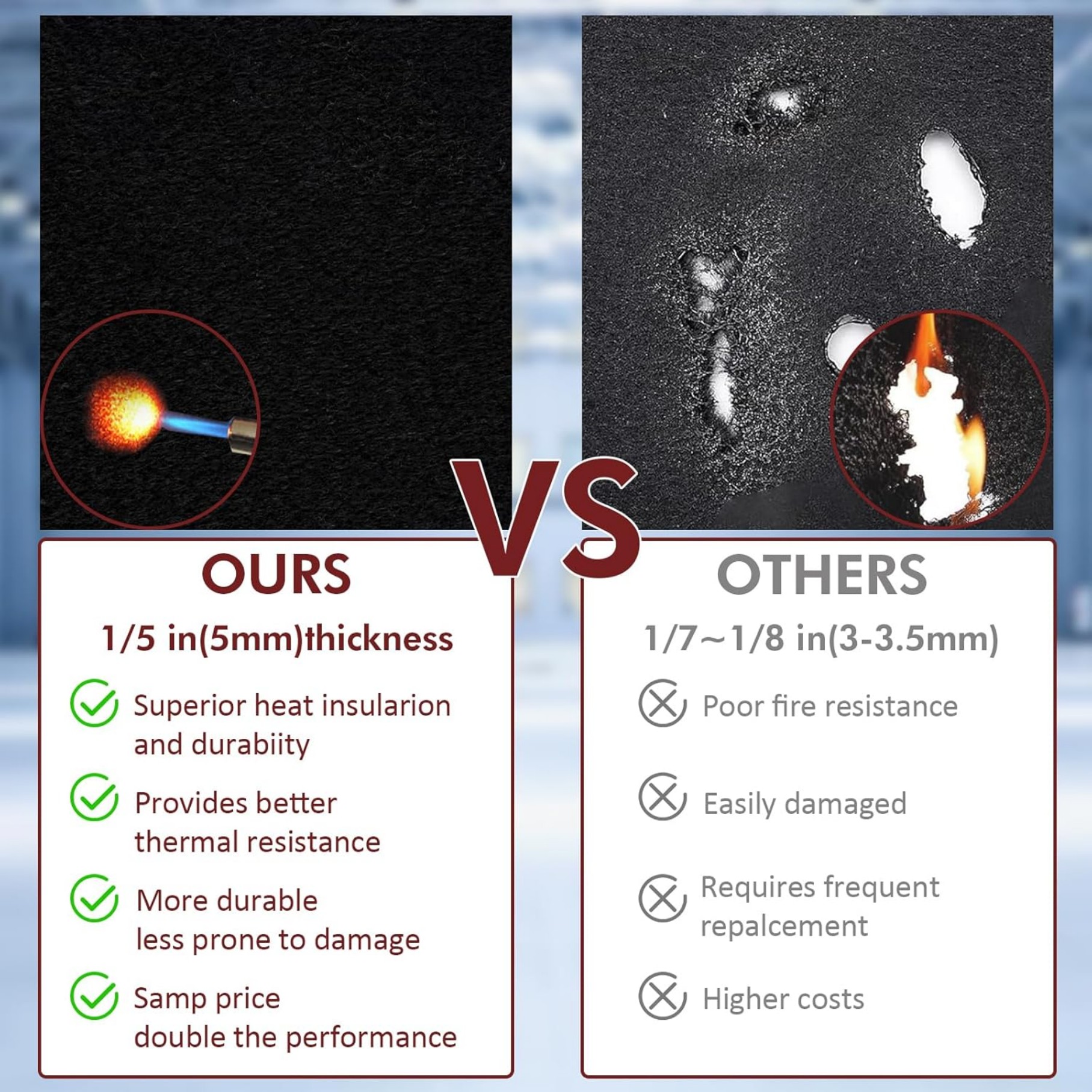

Avoid cheap imported blankets that may contain hazardous materials or degrade quickly under constant heat exposure.

Maintenance and Safety Checks

Inspect your welding blanket pellet stove protection monthly:

- Check for tears or thinning areas

- Verify all fasteners remain secure

- Remove accumulated dust (use a vacuum, not compressed air)

- Test flexibility - brittle blankets need replacement

Replace the blanket every 3-5 years depending on usage. Discoloration alone doesn't indicate failure, but stiffness or fiber separation does.

Efficiency Benefits

Properly installed welding blankets can:

- Reduce heat loss through walls by up to 35%

- Allow closer stove placement to walls (saving floor space)

- Maintain more consistent room temperatures

- Lower pellet consumption by directing heat outward

Combine with a heat-powered stove fan for optimal warmth distribution throughout your space.

Common Mistakes to Avoid

When using welding blankets with pellet stoves, never:

- Cover the stove's top surface (blocks proper venting)

- Use blankets not rated for continuous high heat

- Install directly against combustible materials

- Ignore local building codes for clearance requirements

Always consult your stove manufacturer's guidelines before modifying installations.

Alternative Heat Shield Options

While welding blankets offer flexibility, consider these alternatives:

| Option | Pros | Cons |

|---|---|---|

| Ceramic boards | More rigid, better insulation | Higher cost, difficult to cut |

| Sheet metal | Durable, easy to clean | Requires air gap, conducts heat |

| Vermiculite panels | Excellent insulation | Fragile, limited sizes |

For most DIY installations, welding blankets provide the best balance of performance and affordability.

Final Recommendations

When selecting a welding blanket for your pellet stove:

- Choose OSHA-compliant materials from reputable suppliers

- Measure your space carefully before purchasing

- Consider double-layer installation for extra protection

- Combine with non-combustible floor protection

Properly implemented, a welding blanket pellet stove setup provides safe, efficient heating for years. Always prioritize safety over cost savings when dealing with high-temperature applications.