Post Weld Heat Treatment Blanket: Essential Guide for Industrial Applications

Summary:Post weld heat treatment blankets provide controlled heating for welded components to reduce residual stresses and improve material properties. They offer precise temperature control, energy efficiency, and safety benefits for critical welding applications.

What Is a Post Weld Heat Treatment Blanket?

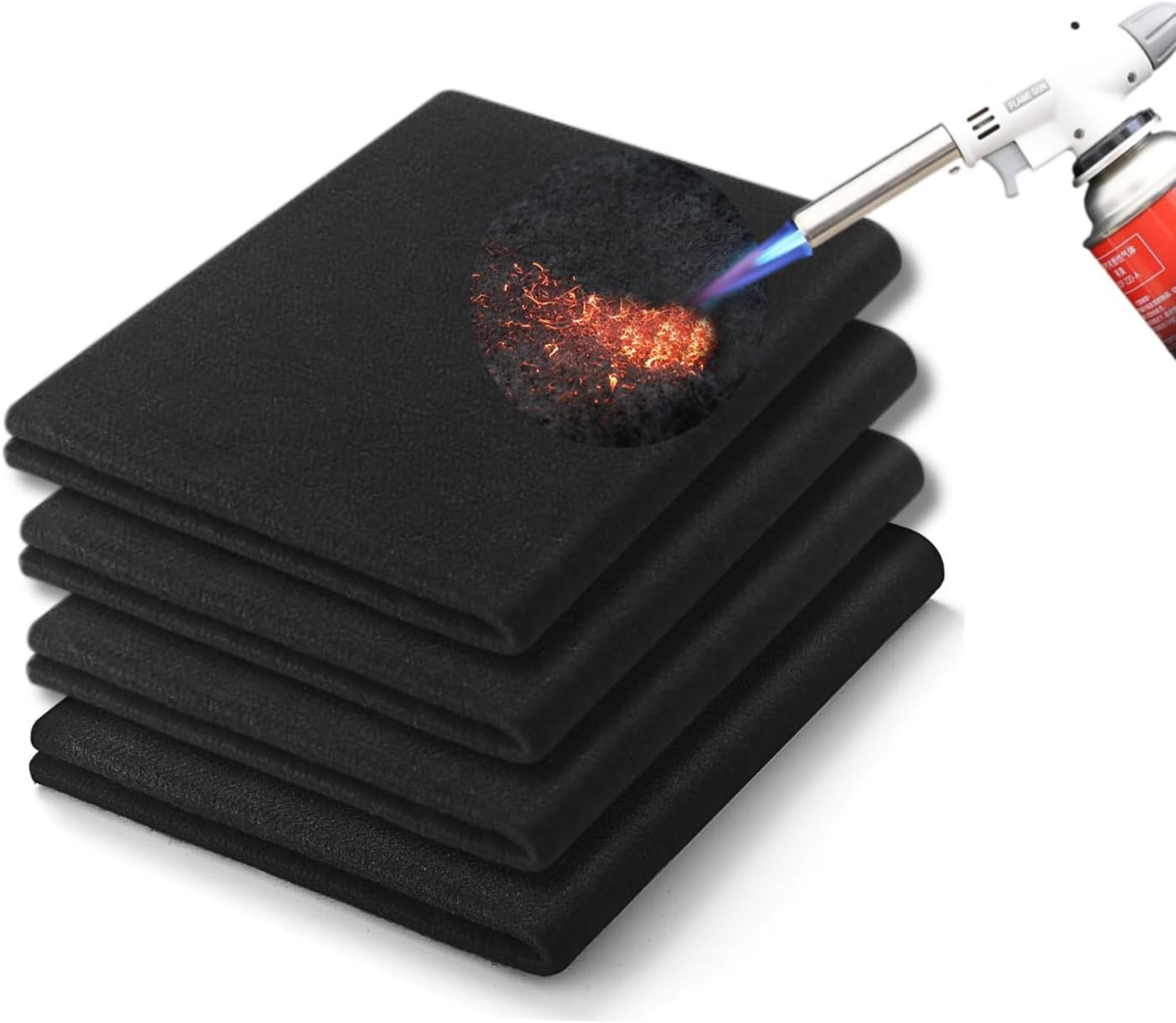

When you weld metal components, the heating and cooling process creates internal stresses that can weaken the structure. A post weld heat treatment (PWHT) blanket solves this problem by applying controlled, uniform heat to the welded area after completion. These flexible heating systems wrap around complex geometries, providing consistent temperatures exactly where you need them.

Modern PWHT blankets use advanced ceramic fiber insulation and embedded heating elements to maintain precise temperature profiles. You'll find them essential for pressure vessels, pipelines, and structural steel applications where weld integrity matters most.

Key Benefits of Using Heat Treatment Blankets

Why should you choose a post weld heat treatment blanket over traditional furnace methods? Consider these advantages:

- Portability:Treat welds onsite without moving large components

- Energy efficiency:Focus heat only where needed, reducing power consumption

- Precision control:Maintain exact temperatures (±5°F) for code compliance

- Safety:Insulated surfaces protect workers from burns

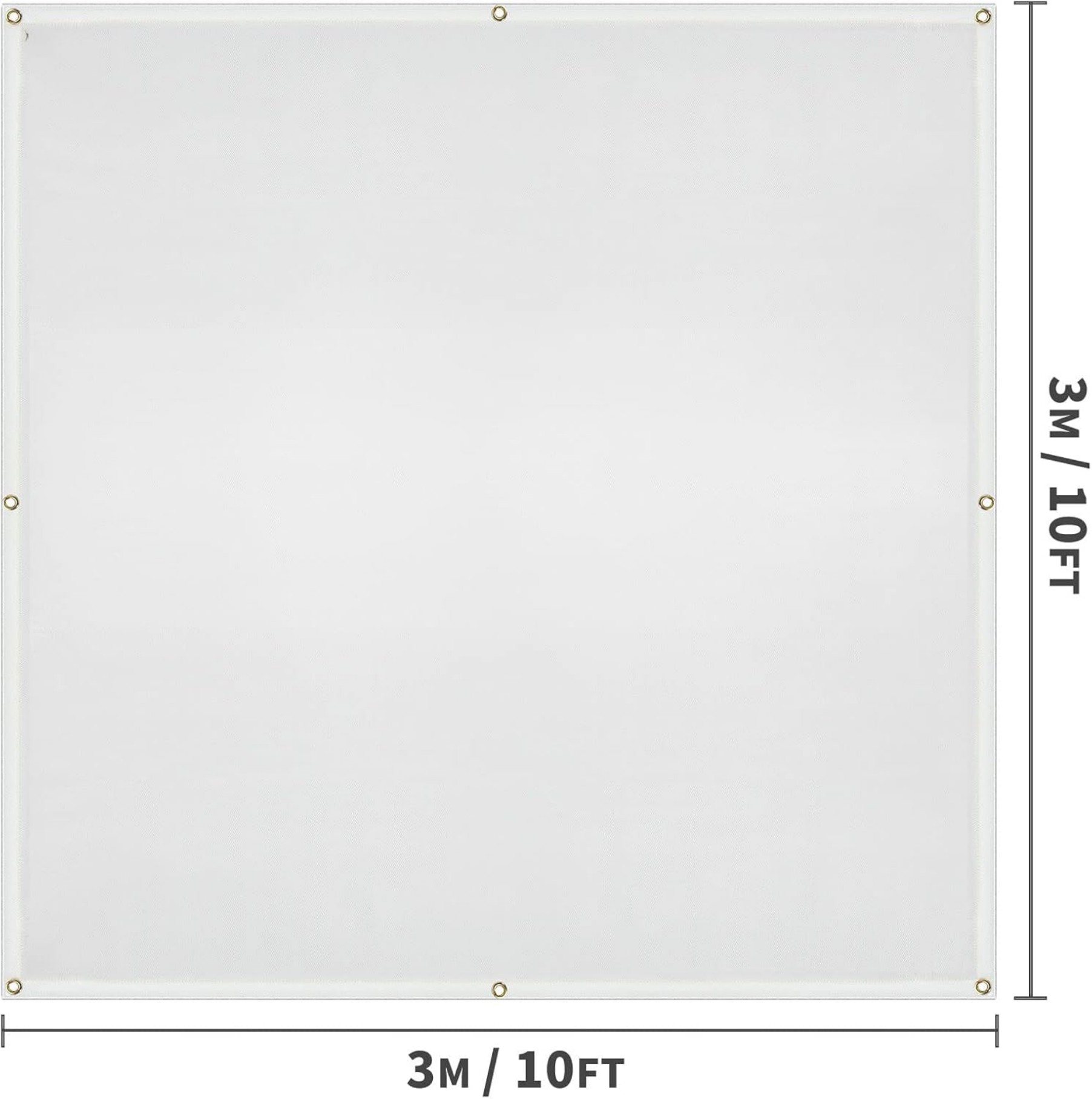

- Versatility:Custom shapes accommodate pipes, tanks, and complex assemblies

How PWHT Blankets Improve Weld Quality

The science behind post weld heat treatment involves three critical processes that occur when you properly apply heat:

- Stress relief:Heating to 1100-1250°F allows dislocations in the metal crystal structure to rearrange, relieving internal stresses from welding

- Hardness reduction:Transforms brittle martensite in the heat-affected zone into softer, tougher structures

- Improved corrosion resistance:Homogenizes the microstructure, reducing galvanic potential differences

With a quality post weld heat treatment blanket, you achieve these metallurgical changes without overheating adjacent areas or causing distortion. Thermocouples connected to digital controllers ensure you maintain temperatures within the optimal range specified by ASME, API, or other applicable codes.

Selecting the Right PWHT Blanket

Not all heat treatment blankets perform equally. When choosing equipment for your application, evaluate these factors:

| Feature | Consideration |

|---|---|

| Temperature range | Match to your material requirements (typically 300-1600°F) |

| Heating element type | Nickel-chromium or Kanthal wires for different power needs |

| Insulation thickness | Thicker insulation improves efficiency but reduces flexibility |

| Control system | Basic thermostats vs. programmable controllers with data logging |

For critical applications, consider blankets with multiple heating zones that allow you to compensate for heat loss at welds near flanges or supports. Reputable manufacturers can create custom configurations for unusual geometries.

Proper Usage Techniques

To get the best results from your post weld heat treatment blanket:

- Clean the weld area thoroughly before application

- Position thermocouples according to code requirements (typically 2" from the weld toe)

- Secure the blanket with straps or clamps to ensure full contact

- Follow the approved heating/cooling rate (usually 100°F per hour)

- Document all temperature readings for quality records

Remember that different materials require specific heat treatment protocols. Carbon steels typically need holding at 1100-1250°F for one hour per inch of thickness, while stainless steels may require solution annealing at higher temperatures.

Industry Applications

Post weld heat treatment blankets serve critical roles across multiple sectors:

- Oil & gas:Pipeline girth welds, pressure vessel repairs

- Power generation:Boiler tubes, turbine components

- Aerospace:Engine mounts, structural airframe welds

- Shipbuilding:Hull plates, piping systems

- Construction:Heavy steel connections in bridges and skyscrapers

In each case, the ability to perform PWHT without disassembling components saves substantial time and labor costs while ensuring compliance with stringent quality standards.

Maintenance and Safety

Proper care extends your post weld heat treatment blanket's lifespan:

- Store rolled or flat in a dry location

- Inspect for damaged heating elements or insulation before each use

- Clean with compressed air - never use liquids

- Test resistance values periodically

Always follow electrical safety protocols when operating PWHT blankets. Ground all equipment properly and use GFCI protection in wet environments. Thermal barriers should protect nearby combustible materials during operation.

Future Trends in PWHT Technology

Innovations in post weld heat treatment blankets include:

- Smart blankets with integrated IoT sensors for remote monitoring

- Advanced insulation materials that reduce heat-up times

- Hybrid systems combining induction heating with blanket insulation

- AI-powered controllers that automatically adjust for environmental conditions

These developments will make PWHT more efficient and reliable while providing better documentation for quality assurance purposes.

Conclusion

A post weld heat treatment blanket represents a smart investment for any operation involving critical welds. By understanding proper selection criteria, application techniques, and maintenance requirements, you can consistently achieve high-quality results that meet industry standards. Whether you're working on pipelines, pressure vessels, or structural steel, these versatile tools deliver precise, efficient heat treatment where conventional methods can't.