How Thermal Blankets for Welding Improve Safety and Efficiency

Thermal blankets for welding protect workers and equipment from sparks, heat, and molten metal. They prevent fire hazards while maintaining weld quality. This guide explains their benefits, types, and proper usage to enhance your welding operations.

What Is a Thermal Blanket for Welding?

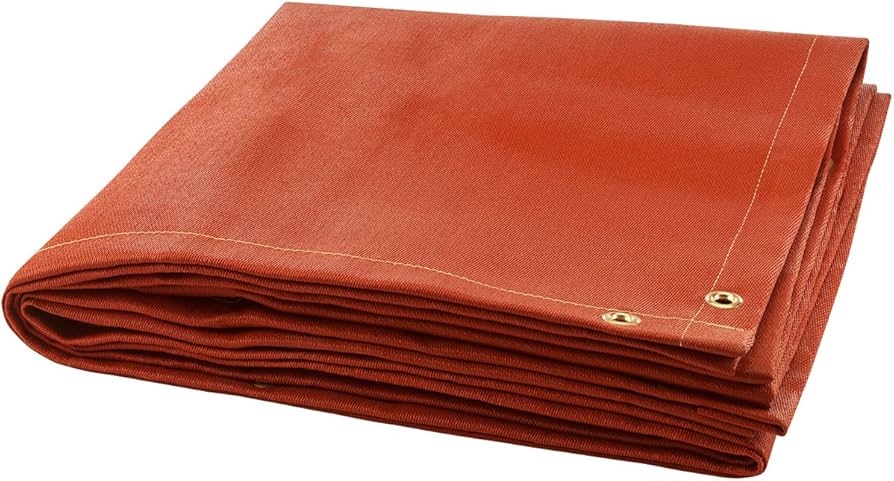

A thermal blanket for welding is a protective cover made from heat-resistant materials like fiberglass or silica. You use it to shield nearby surfaces from welding sparks and radiant heat. These blankets typically withstand temperatures up to 2000°F (1093°C), making them essential for safe welding environments.

Key Benefits of Using Welding Thermal Blankets

When you use thermal blankets for welding, you gain multiple advantages:

- Fire prevention:They stop sparks from igniting flammable materials within 10 feet of your work area

- Heat containment:Reduces heat transfer to surrounding equipment by up to 80%

- Surface protection:Prevents weld spatter from damaging expensive machinery or finished surfaces

- Improved efficiency:Lets you weld near sensitive areas without shutdowns

- Regulatory compliance:Meets OSHA and NFPA safety standards for hot work

Types of Thermal Blankets for Different Welding Applications

Choose the right thermal blanket based on your specific welding needs:

1. Fiberglass Welding Blankets

These are your most economical option, suitable for general-purpose welding. The fiberglass fabric resists temperatures up to 1000°F (538°C). You'll find them useful for:

- MIG welding on construction sites

- Shielded metal arc welding (SMAW)

- Temporary protection during maintenance welding

2. Silica Thermal Blankets

When you need higher temperature resistance (up to 2000°F/1093°C), silica blankets perform better. Their tightly woven construction makes them ideal for:

- TIG welding of aerospace components

- Plasma arc cutting operations

- High-amperage submerged arc welding

3. Multi-Layer Insulated Blankets

These premium thermal blankets combine different materials for maximum protection. You'll appreciate their:

- Aluminum outer layer that reflects radiant heat

- Ceramic fiber middle layer for insulation

- Stainless steel wire reinforcement for durability

Proper Installation of Your Welding Thermal Blanket

To get the most from your thermal blanket for welding, follow these installation tips:

- Clean the surface before applying the blanket

- Overlap multiple blankets by at least 6 inches for complete coverage

- Secure edges with high-temperature tape or clamps

- Inspect for gaps where sparks could escape

- Replace blankets showing significant wear or burn marks

Maintenance Tips for Long-Lasting Performance

Your thermal welding blanket lasts longer when you:

- Shake off slag and debris after each use

- Store flat or rolled (never folded) to prevent creases

- Wash with compressed air, never water or chemicals

- Rotate between multiple blankets to distribute wear

- Conduct monthly inspections for thinning areas

Common Mistakes to Avoid With Welding Blankets

Even experienced welders sometimes make these errors with thermal blankets:

- Using undersized blankets that leave gaps in coverage

- Placing blankets directly against extremely hot surfaces (use standoffs)

- Reusing blankets with melted synthetic fibers (creates toxic fumes)

- Assuming blankets eliminate the need for fire watches

- Choosing price over proper temperature rating

When to Replace Your Thermal Blanket

Watch for these signs that your welding thermal blanket needs replacement:

- Visible holes larger than 1/4 inch diameter

- Stiffness or brittleness in the material

- Discoloration indicating chemical degradation

- Reduced flexibility that prevents proper draping

- Any area that glows red during use

Conclusion

A quality thermal blanket for welding protects your worksite while improving productivity. By selecting the right type and maintaining it properly, you create safer welding conditions that comply with industry standards. Remember that no blanket eliminates all risks - always combine thermal protection with proper ventilation and fire watches.