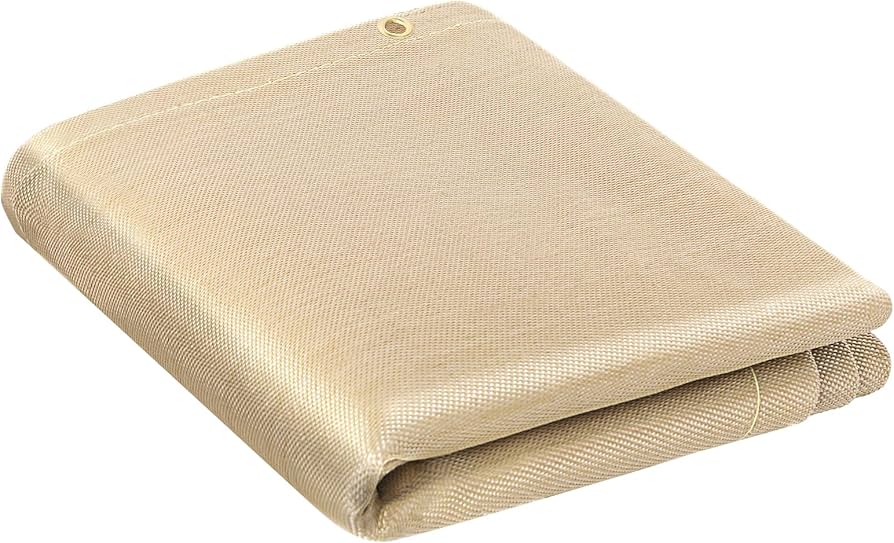

Silica Welding Blanket Welding: Safety and Efficiency in High-Temperature Applications

Summary:Silica welding blankets provide essential protection during welding operations. These fire-resistant covers shield workers and equipment from sparks, heat, and molten metal splatter, making them indispensable for safe welding practices.

What Is a Silica Welding Blanket?

When you're welding, a silica welding blanket acts as your first line of defense against heat and sparks. Made from woven silica fibers, these blankets withstand temperatures up to 1800°F (982°C). Unlike regular fabrics, they won't catch fire or melt when exposed to welding sparks.

The silica fibers create a flexible yet durable barrier that you can drape over equipment, work surfaces, or even use as personal protection. Their lightweight nature makes them easy to handle while providing exceptional thermal insulation.

Key Benefits of Using Silica Welding Blankets

1. Superior Heat Resistance:You get reliable protection from welding arcs, molten metal, and radiant heat. The silica material reflects heat rather than absorbing it.

2. Non-Combustible:Unlike regular tarps, silica blankets won't ignite when sparks land on them. This significantly reduces fire risks in your workspace.

3. Chemical Resistance:They resist most acids, alkalis, and solvents commonly found in industrial environments.

4. Reusable:With proper care, your silica welding blanket lasts through multiple projects, making it cost-effective.

Proper Usage Techniques for Silica Welding Blankets

To maximize protection during silica welding blanket welding:

- Coverage Area:Ensure the blanket extends at least 12 inches beyond your work area to catch all sparks and slag.

- Secure Placement:Use welding blanket clips or weights to prevent movement during work. Never let it hang loosely near your welding zone.

- Layering:For extra protection in high-heat applications, layer two blankets with a 6-inch overlap.

- Personal Protection:Drape a smaller silica blanket over your lap when sitting or kneeling near welding operations.

Maintenance and Care for Longevity

Your silica welding blanket requires minimal but proper maintenance:

- Cleaning:Shake off loose debris regularly. For stubborn deposits, use compressed air or a soft brush. Never machine wash.

- Inspection:Before each use, check for tears, thinning areas, or excessive stiffness that indicates material degradation.

- Storage:Hang vertically or roll loosely. Avoid tight folds that can weaken fibers over time.

- Replacement:Replace your blanket when you notice significant fiber breakdown or reduced flexibility.

Choosing the Right Silica Welding Blanket

Consider these factors when selecting your silica welding blanket:

1. Temperature Rating:Match the blanket's maximum temperature rating to your specific welding processes.

2. Thickness:Thicker blankets (1/4" or more) offer better protection for high-amperage welding.

3. Size:Measure your work area and add safety margins. Common sizes range from 4'x4' to 10'x10'.

4. Edge Treatment:Look for reinforced edges with grommets for secure attachment points.

Safety Precautions When Using Silica Blankets

While silica welding blanket welding improves safety, remember:

- Always wear proper PPE (gloves, helmet, protective clothing) even when using blankets

- Never use damaged blankets - small tears can rapidly expand under heat stress

- Keep blankets away from sharp tools that could puncture them

- Allow blankets to cool completely before handling or storing

- Maintain proper ventilation - silica fibers can irritate lungs if airborne

Comparing Silica to Other Welding Blanket Materials

Silica outperforms alternatives in many welding scenarios:

- Fiberglass:Silica handles higher temperatures and resists chemical degradation better

- Leather:More flexible and lighter than leather welding pads

- Ceramic:More cost-effective than ceramic fiber blankets for most welding applications

- Asbestos:Safer alternative with similar heat resistance (asbestos is banned in many countries)

Innovations in Silica Welding Blanket Technology

Recent advancements enhance silica welding blanket performance:

- Multi-layer designs:Combining silica with other materials for specific applications

- Improved flexibility:New weaving techniques create more pliable blankets

- Color coding:Quick visual identification of temperature ratings

- Anti-static treatments:Reducing spark generation in sensitive environments

Common Applications Beyond Welding

Your silica welding blanket serves multiple purposes:

- Foundry work and metal casting protection

- Fire containment in industrial settings

- Thermal insulation for pipes and equipment

- Spark protection during grinding operations

- Emergency fire blankets in workshops

By understanding proper silica welding blanket welding techniques, you significantly improve worksite safety and efficiency. These versatile protective tools represent a smart investment for any welding professional or hobbyist working with high temperatures.