DIY Welding Blanket Guide: How to Make Your Own Fire-Resistant Protection

This guide shows you how to create a welding blanket DIY project safely. Learn about materials, construction methods, and safety considerations for making effective fire-resistant protection at home.

Why Consider a Welding Blanket DIY Project?

Commercial welding blankets can be expensive, especially for hobbyists. A welding blanket DIY solution lets you customize size and thickness while saving money. However, you must understand the safety requirements before starting.

Essential Materials for Your Welding Blanket DIY Project

For a functional welding blanket, you need:

- Fiberglass fabric (minimum 18 oz/sq yd)

- High-temperature silicone adhesive

- Stainless steel grommets

- Fire-resistant thread

- Heavy-duty sewing machine (industrial grade recommended)

Step-by-Step Welding Blanket DIY Construction

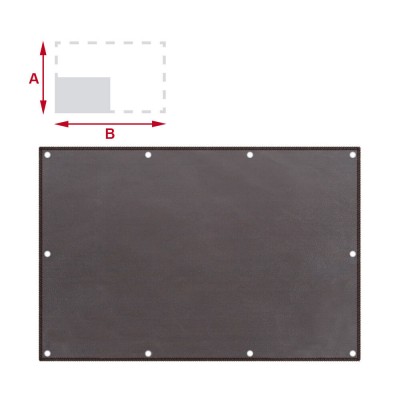

- Measure and cut:Determine your needed size (common sizes are 4'x6' or 6'x8') and cut the fiberglass fabric with sharp scissors.

- Reinforce edges:Fold over 1 inch of material on all sides and stitch with fire-resistant thread.

- Add grommets:Install stainless steel grommets every 12-18 inches along the edges for hanging.

- Layer construction (optional):For extra protection, create a double-layer blanket with silicone adhesive between layers.

- Final inspection:Check all seams and grommets for secure attachment.

Safety Considerations for Welding Blanket DIY Projects

Your homemade welding blanket must meet basic safety standards:

- Materials must withstand at least 1000°F (540°C)

- Avoid materials that produce toxic fumes when heated

- Never use treated fabrics that may contain harmful chemicals

- Test small samples before committing to full blanket construction

When to Buy Instead of Making a Welding Blanket DIY

Consider purchasing a commercial welding blanket if:

- You need certified protection for professional work

- Your project involves extremely high temperatures (above 1500°F)

- You require specific safety certifications

- The time/materials cost exceeds commercial options

Maintaining Your DIY Welding Blanket

Proper care extends your blanket's life:

- Shake off debris after each use

- Store flat or rolled (never folded) to prevent crease damage

- Inspect for damage before each use

- Replace if you notice significant wear or holes

Alternative Uses for Your Welding Blanket DIY Creation

Beyond welding, your blanket can:

- Protect work surfaces from hot metal

- Serve as emergency fire protection

- Provide heat shielding for automotive work

- Act as a spark barrier during grinding operations

Final Thoughts on Welding Blanket DIY Projects

Creating your own welding blanket can be rewarding, but safety comes first. If you're unsure about any aspect, consult with welding professionals or consider purchasing a commercially rated blanket for critical applications.