Welding Blankets: Essential Protection for Safe Welding Operations

Welding blankets are crucial safety tools that protect workers and surfaces from sparks, heat, and molten metal. This guide explains their types, materials, proper use, and maintenance to help you choose the right protection for your welding projects.

What Are Welding Blankets?

Welding blankets are heat-resistant protective covers made from specialized materials that withstand extreme temperatures. You use them to shield floors, walls, equipment, and even yourself from welding sparks, slag, and radiant heat. Unlike regular fabrics, welding blankets won't catch fire when exposed to welding temperatures that can reach 3,000°F (1,650°C).

Key Benefits of Using Welding Blankets

- Fire prevention:They stop sparks from igniting flammable materials nearby

- Surface protection:Prevent damage to floors, walls, and valuable equipment

- Safety compliance:Help meet OSHA and workplace safety requirements

- Versatility:Can be used as curtains, floor covers, or wrap-around protection

- Reusable:High-quality welding blankets last through multiple projects

Types of Welding Blankets and Their Uses

Not all welding blankets are the same. The right choice depends on your specific welding application:

Fiberglass Welding Blankets

These are the most common type you'll find. Made from woven fiberglass with silicone or other coatings, they typically withstand temperatures up to 1,000°F (540°C). You'll want these for general-purpose welding protection where extreme heat isn't a factor.

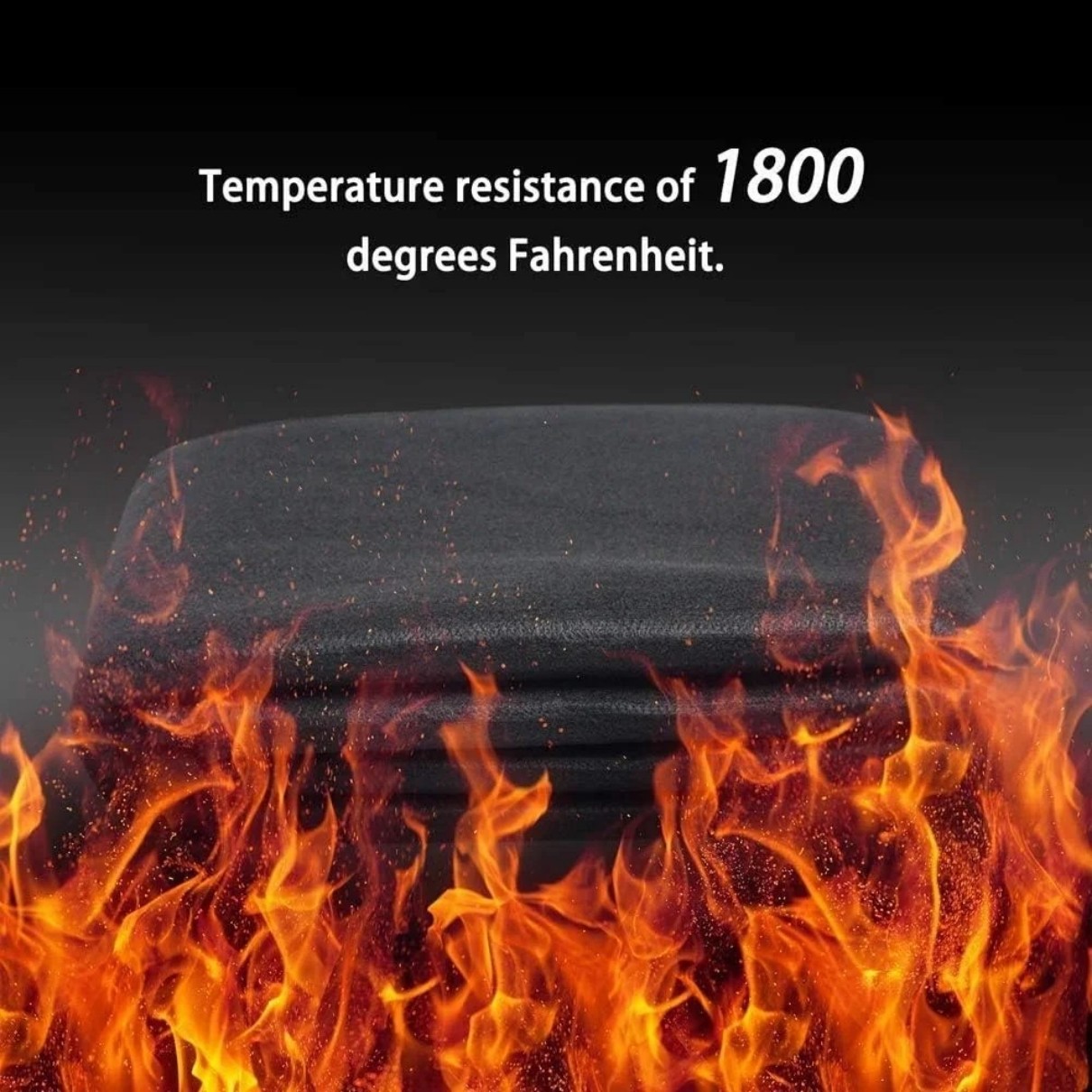

Silica Welding Blankets

When you need higher temperature resistance (up to 1,800°F or 980°C), silica blankets are your best option. They're more flexible than fiberglass and work well for plasma cutting and high-heat welding applications.

Leather Welding Blankets

For the ultimate in durability and heat resistance (up to 2,000°F or 1,100°C), leather welding blankets can't be beat. They're heavier and more expensive, but perfect for foundries or continuous high-heat work.

Pro Tip:Always check the temperature rating of your welding blanket before use. Using a blanket rated for lower temperatures than your welding process generates is a serious safety hazard.

How to Choose the Right Welding Blanket

Selecting the appropriate welding blanket involves considering several factors:

- Welding process:MIG, TIG, and stick welding generate different heat levels

- Material thickness:Thicker blankets offer better protection but are less flexible

- Size requirements:Measure your work area to ensure complete coverage

- Mobility needs:If you move around frequently, consider lighter options

- Chemical exposure:Some coatings resist oils and chemicals better than others

Proper Use and Maintenance of Welding Blankets

To get the most from your welding blanket and ensure safety:

- Inspect before each use for tears, holes, or excessive wear

- Secure properly to prevent shifting during work

- Overlap multiple blankets if needed for complete coverage

- Clean regularly according to manufacturer instructions

- Store in a dry place away from direct sunlight when not in use

- Replace when the material becomes brittle or shows significant damage

Common Mistakes to Avoid

Even experienced welders sometimes make these errors with welding blankets:

- Using the same blanket for all welding processes regardless of heat levels

- Folding or storing blankets while still hot

- Ignoring small holes that can rapidly expand under heat stress

- Placing blankets directly against highly flammable surfaces

- Assuming all welding blankets are equal in quality and protection

Welding Blanket Safety Standards

Quality welding blankets meet specific safety standards:

- OSHA 1910.252:Covers welding, cutting, and brazing safety requirements

- NFPA 51B:Standard for fire prevention during welding operations

- ASTM F955:Standard test method for evaluating heat transfer through materials

Always verify that your welding blanket meets relevant standards for your industry and application.

Beyond Welding: Other Uses for Welding Blankets

While designed for welding, these versatile blankets have other applications:

- Protecting surfaces during grinding or cutting operations

- Insulating pipes or equipment during cold weather

- Creating temporary heat shields in automotive work

- Protecting floors during painting or chemical applications

- Emergency fire blankets in workshops

Remember:While welding blankets have multiple uses, never use them for purposes that exceed their temperature ratings or for which they weren't designed.

Investing in Quality Welding Blankets

High-quality welding blankets might cost more initially but save money long-term through:

- Longer service life with proper care

- Better protection reducing damage to other equipment

- Lower replacement frequency

- Improved safety reducing accident risks

When purchasing, look for reputable brands that provide clear specifications and safety certifications.

Conclusion

Welding blankets are essential safety tools that protect both people and property during welding operations. By understanding the different types, proper selection criteria, and correct usage techniques, you can significantly improve worksite safety. Always prioritize quality and appropriate specifications over price when choosing welding blankets, as they serve as your first line of defense against welding hazards.