Welding Blanket Fabric: Heat-Resistant Protection for Safe Metalwork

Summary:Welding blanket fabric protects against sparks, slag, and heat in metalworking. This guide explains its materials, safety ratings, proper use, and maintenance to help you choose the right protection for your welding projects.

What Is Welding Blanket Fabric?

Welding blanket fabric is a specialized heat-resistant material designed to protect workers and workspaces from welding hazards. When you're welding, cutting, or grinding metal, sparks and molten slag can reach temperatures over 2,000°F (1,093°C). Standard fabrics would instantly catch fire at these temperatures, but welding blanket fabric resists ignition and contains these dangerous elements.

Key Materials in Welding Blankets

You'll find three primary materials used in quality welding blanket fabric:

- Fiberglass:The most common choice, offering good heat resistance up to 1,000°F (538°C) for standard grades. Some industrial fiberglass blankets withstand 1,800°F (982°C).

- Silica:Premium option that handles continuous exposure to 2,000°F (1,093°C) and brief spikes to 3,000°F (1,649°C). More flexible than fiberglass.

- Carbon Fiber:Used in aerospace applications, resisting up to 5,000°F (2,760°C) but significantly more expensive.

Why You Need Proper Welding Blanket Fabric

Using the right welding blanket fabric prevents workplace accidents and property damage. Without proper protection:

- Sparks can ignite nearby flammable materials

- Molten metal droplets burn through surfaces

- Radiant heat damages sensitive equipment

- UV radiation from welding arcs harms unprotected eyes

Quality welding blanket fabric acts as both a physical barrier and heat sink, absorbing and dissipating thermal energy safely.

Choosing the Right Welding Blanket Fabric

Consider these factors when selecting welding blanket fabric:

- Temperature Rating:Match the fabric's maximum temperature to your welding process (MIG, TIG, or stick welding produce different heat levels)

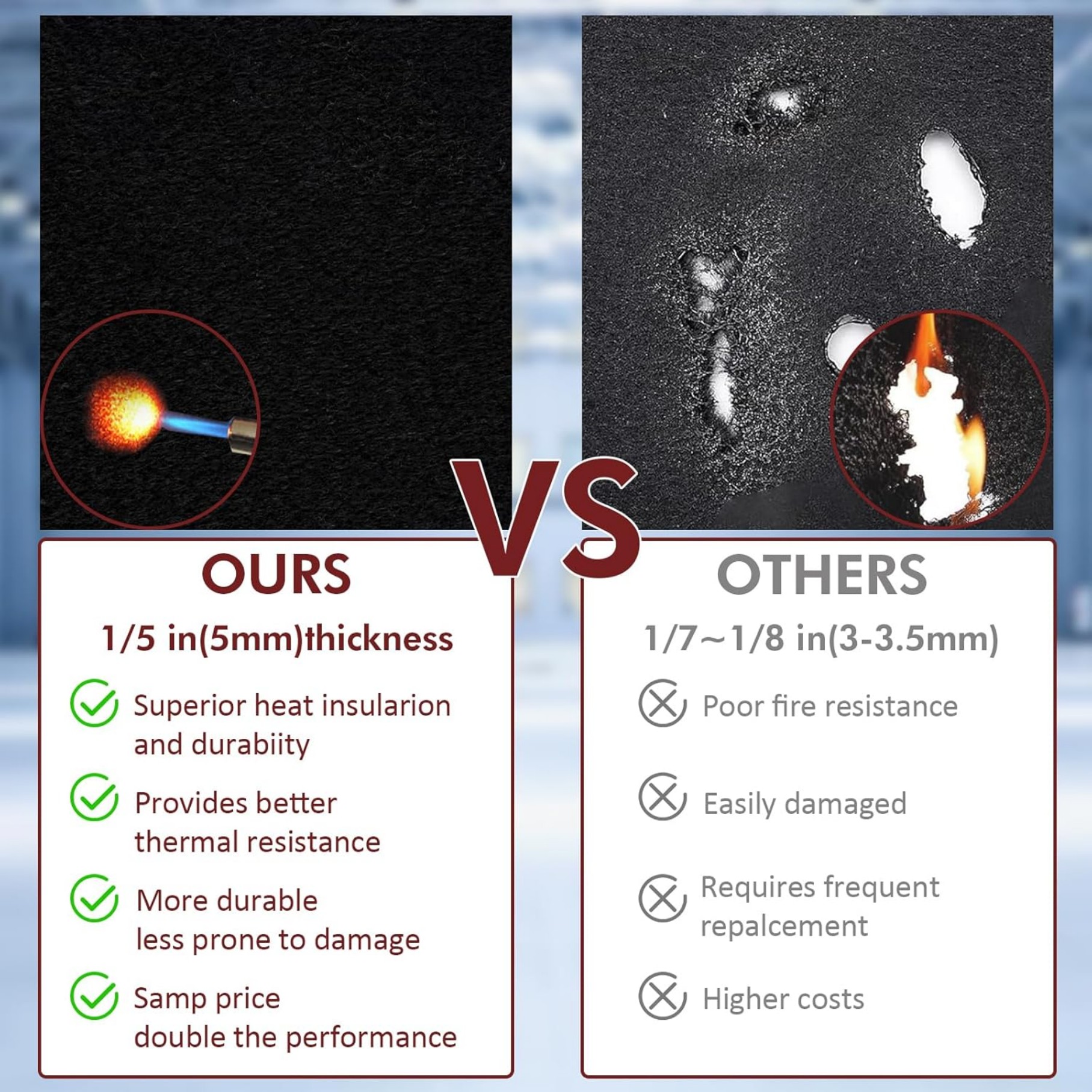

- Thickness:Thicker fabrics (1/8" to 1/4") offer better protection but reduce flexibility

- Size:Standard sizes range from 4'x6' for small jobs to 12'x12' for large work areas

- Edge Treatment:Look for reinforced edges with grommets for secure hanging

- Certifications:OSHA-compliant fabrics meet specific safety standards

Proper Use and Maintenance

To get the most from your welding blanket fabric:

- Always overlap multiple blankets by at least 6 inches when covering large areas

- Secure edges with non-flammable fasteners - never use plastic ties

- Inspect regularly for holes or thinning areas

- Clean with compressed air or a soft brush - never wash welding blankets

- Store flat or rolled - folding creates weak points

Replace welding blanket fabric when it shows significant wear, as compromised material drastically reduces protection.

Specialized Welding Blanket Applications

Beyond standard welding protection, specialized welding blanket fabric serves unique purposes:

- Pipe Welding Blankets:Flexible cylindrical designs that wrap around pipes

- UV-Blocking Blankets:Contain reflective surfaces to protect bystanders from arc flash

- Absorbent Blankets:Combine heat resistance with oil/chemical absorption for hazardous environments

- Custom-Shaped Blankets:Pre-cut to protect specific machinery components

Cost vs. Quality Considerations

While budget welding blanket fabric might seem attractive, remember:

- Premium fabrics last 3-5 times longer than cheap alternatives

- Higher-rated materials protect against more severe accidents

- Quality certifications ensure actual performance matches claims

- Industrial-grade fabrics often pay for themselves in reduced replacement costs

For occasional home use, fiberglass blankets offer good value. Professional welders should invest in silica-based fabrics for daily use.

Safety First With Proper Protection

Welding blanket fabric is your first line of defense against workplace fires and injuries. By understanding the materials, proper selection criteria, and maintenance requirements, you ensure maximum protection for every welding project. Always prioritize certified, appropriately-rated fabrics over cheaper alternatives - your safety depends on it.