Carbon Fiber Welding Blankets: Superior Heat Protection for Industrial Use

Carbon fiber welding blankets provide exceptional heat resistance and durability for welding applications. These specialized protective covers shield surfaces from sparks, slag, and extreme temperatures while offering flexibility and longevity.

What Are Carbon Fiber Welding Blankets?

Carbon fiber welding blankets are high-performance protective covers made from woven carbon fiber fabric. Unlike traditional welding blankets, they combine extreme heat resistance (up to 2000°F/1093°C) with lightweight flexibility. The carbon fiber construction creates a thermal barrier that reflects radiant heat while resisting direct flame contact.

Key Benefits of Carbon Fiber Welding Blankets

When you choose carbon fiber welding blankets, you get several advantages over conventional materials:

- Unmatched heat resistance:Withstand temperatures that would melt ordinary fabrics

- Durability:Resist tears, abrasions, and chemical exposure common in welding environments

- Lightweight:Easy to handle and position without compromising protection

- Non-conductive:Safe for electrical work environments

- Reusable:Unlike disposable alternatives, these blankets last for years

Applications of Carbon Fiber Welding Blankets

These versatile blankets serve multiple purposes in industrial settings:

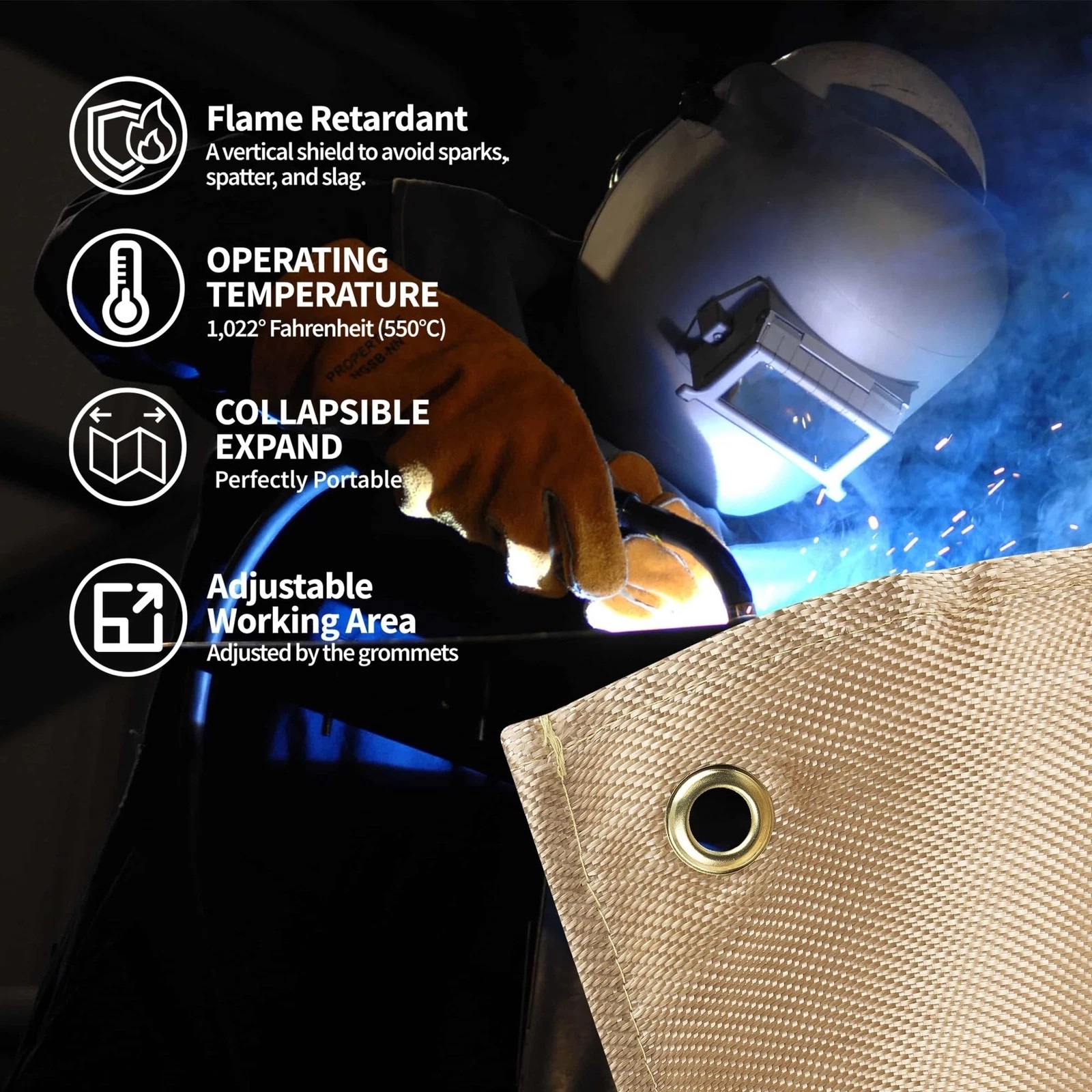

Welding protection:Shield floors, walls, and equipment from sparks and spatter during MIG, TIG, and arc welding operations. The carbon fiber material won't burn through like cotton or fiberglass alternatives.

Heat containment:Use them to contain heat in furnace maintenance or metal casting applications. Their reflective properties help maintain consistent temperatures.

Fire barriers:Install as temporary fire protection during hot work in sensitive areas. Many facilities use them for compliance with fire safety regulations.

Choosing the Right Carbon Fiber Welding Blanket

Consider these factors when selecting your welding blanket:

- Temperature rating:Match the blanket's maximum temperature to your specific application needs

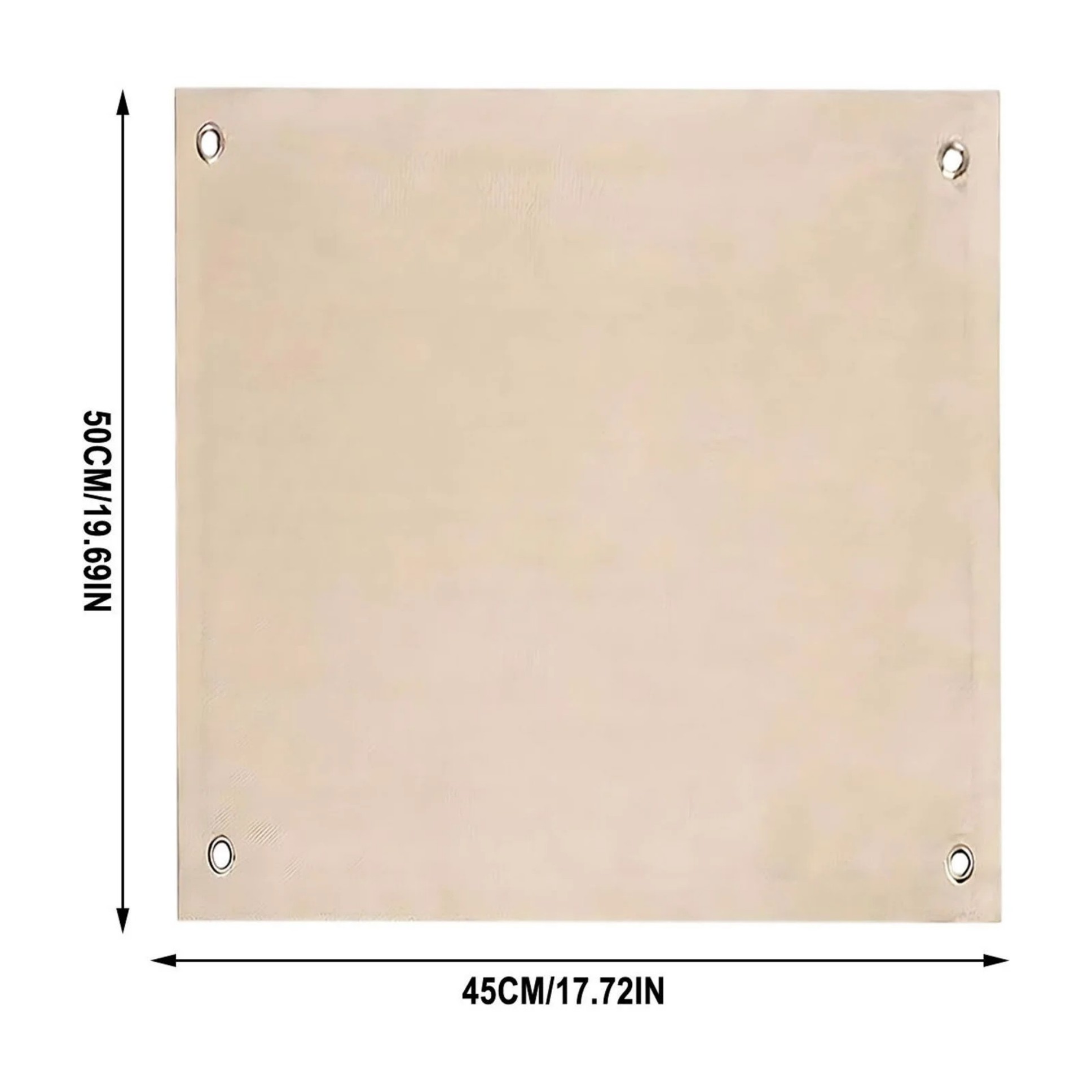

- Size:Measure the area you need to protect and allow for overlap

- Thickness:Thicker blankets offer more protection but may be less flexible

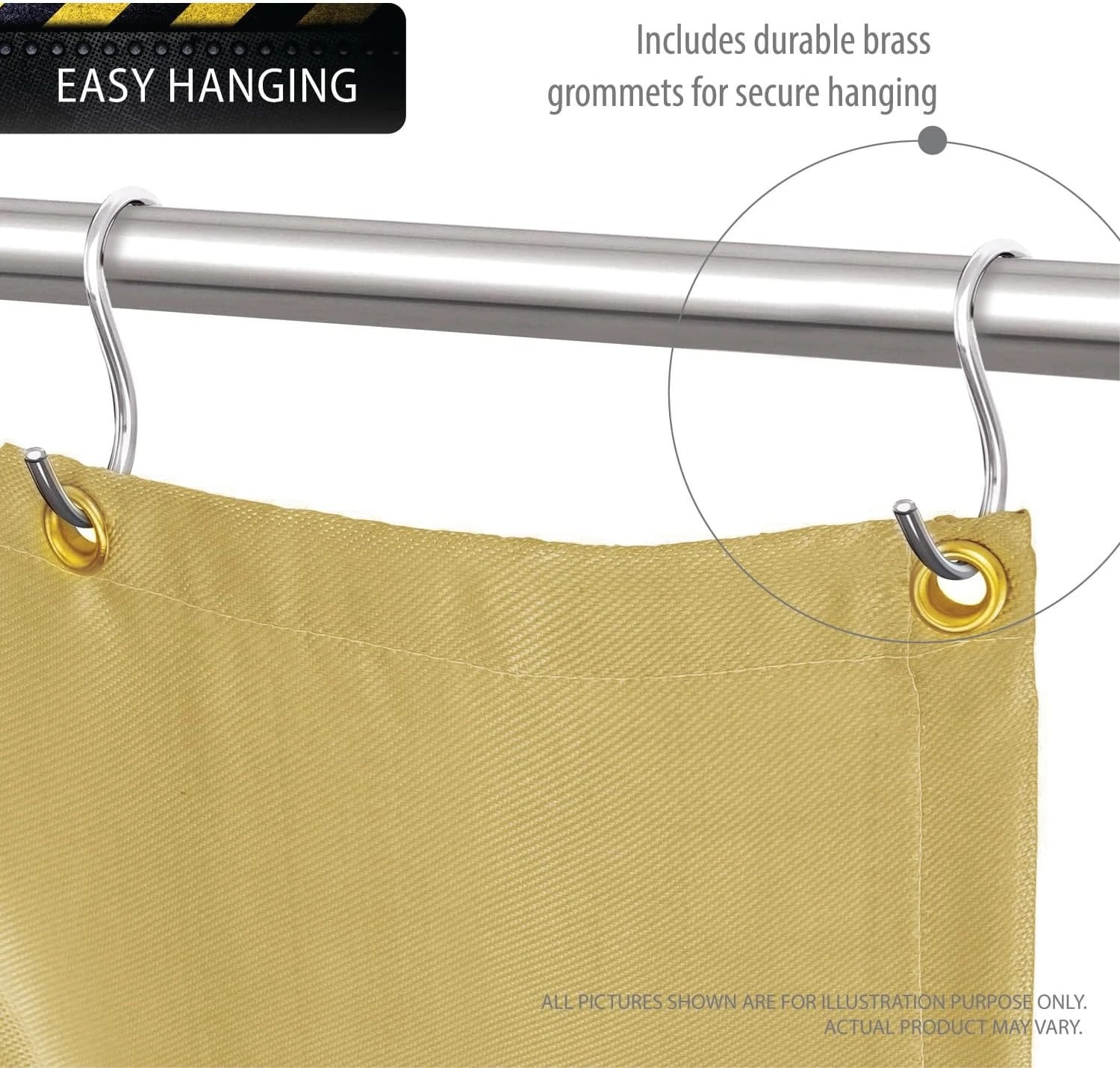

- Edge treatment:Look for reinforced edges with grommets for secure fastening

- Certifications:Check for relevant industry standards compliance

Proper Use and Maintenance

To maximize the lifespan of your carbon fiber welding blanket:

- Inspect regularly for damage before each use

- Clean with compressed air or a soft brush - avoid harsh chemicals

- Store flat or rolled in a dry, clean area when not in use

- Replace if you notice significant fraying or heat damage

Carbon Fiber vs. Other Welding Blanket Materials

Compared to fiberglass or silica alternatives, carbon fiber welding blankets offer:

| Feature | Carbon Fiber | Fiberglass | Silica |

|---|---|---|---|

| Max Temperature | 2000°F | 1000°F | 1800°F |

| Weight | Lightest | Heavy | Medium |

| Flexibility | Excellent | Poor | Good |

| Lifespan | Longest | Short | Medium |

Safety Considerations

While carbon fiber welding blankets provide excellent protection, remember:

- They supplement but don't replace proper personal protective equipment (PPE)

- Always follow standard welding safety protocols

- Never use damaged blankets - small holes can compromise protection

- Ensure proper ventilation when working with heated carbon fiber materials

Where to Buy Quality Carbon Fiber Welding Blankets

Purchase from reputable industrial safety suppliers who provide:

- Detailed product specifications

- Manufacturer warranties

- Technical support for proper selection

- Custom sizing options when needed

Investing in high-quality carbon fiber welding blankets protects your equipment, facility, and most importantly - your workers. Their superior performance justifies the higher initial cost through extended service life and reliable protection.