Top Glassfiber Welding Blanket Exporter | High-Temp Safety Solutions

This article explains why glassfiber welding blankets are essential for industrial safety, how to choose a reliable glassfiber welding blanket exporter, and key features of premium welding protection products.

Why You Need Glassfiber Welding Blankets

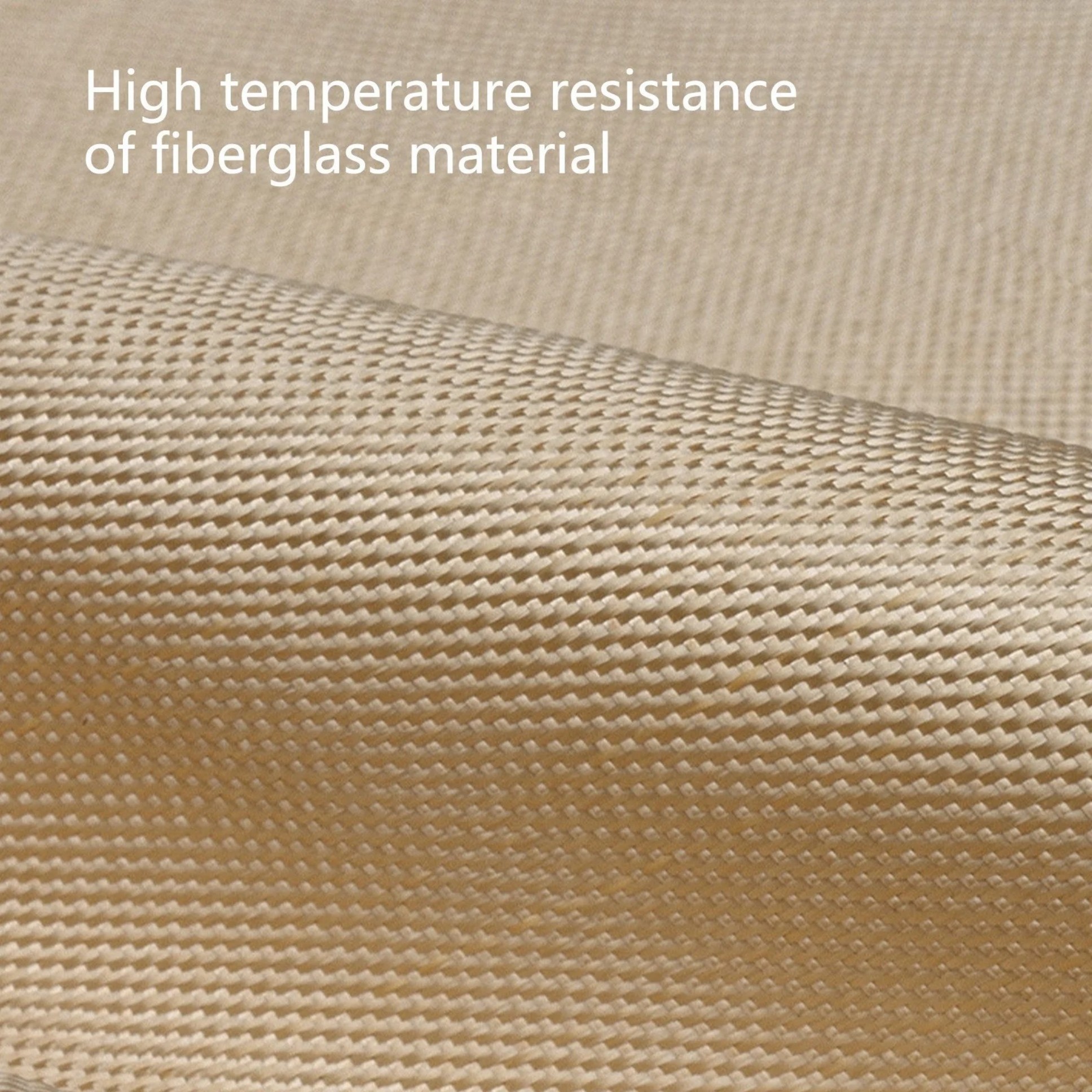

When working with high-temperature processes, safety becomes your top priority. Glassfiber welding blankets provide critical protection against sparks, molten metal splashes, and radiant heat. Unlike ordinary fabrics, these specialized blankets can withstand temperatures up to 1000°C (1832°F) without degrading.

A professional glassfiber welding blanket exporter will offer products with tightly woven fiberglass construction and silicone coatings. This combination creates a flexible yet durable barrier that won't tear easily during daily use. The best blankets maintain their protective qualities even after repeated exposure to welding arcs and grinding sparks.

How to Identify a Quality Glassfiber Welding Blanket Exporter

When selecting a glassfiber welding blanket exporter, consider these key factors:

- Material certifications:Look for ISO 9001 certified manufacturers

- Temperature ratings:Verify the maximum continuous working temperature

- Customization options:Reputable exporters offer various sizes and thicknesses

- Safety standards:Products should meet ANSI, OSHA, or EU safety requirements

- Export experience:Choose suppliers with global shipping capabilities

Top-tier glassfiber welding blanket exporters provide detailed product specifications and safety data sheets. They understand international shipping requirements for fire-resistant materials and can advise on proper blanket selection for your specific application.

Technical Advantages of Glassfiber Welding Blankets

Modern glassfiber welding blankets offer several technical benefits:

- Non-combustible:Won't ignite or support flame spread

- Low thermal conductivity:Provides effective heat insulation

- Chemical resistance:Withstands exposure to most industrial chemicals

- Flexibility:Easily conforms to irregular surfaces

- Long service life:Resists wear from abrasion and folding

When sourcing from a glassfiber welding blanket exporter, ask about reinforced edges and grommet options for secure installation. High-quality blankets often feature double-stitched seams with high-temp thread for added durability in demanding environments.

Applications Across Industries

Glassfiber welding blankets serve multiple industries:

- Metal fabrication:Protects nearby equipment during welding

- Shipbuilding:Contains sparks in confined spaces

- Construction:Creates safe work zones on job sites

- Automotive:Shields sensitive components during repairs

- Oil & gas:Provides fire protection in hazardous areas

A specialized glassfiber welding blanket exporter understands these diverse applications and can recommend appropriate products. For example, marine environments may require saltwater-resistant coatings, while chemical plants might need acid-proof variants.

Maintenance and Care Tips

To maximize your investment from a glassfiber welding blanket exporter:

- Inspect blankets regularly for tears or excessive wear

- Clean with compressed air or soft brush - avoid harsh chemicals

- Store flat or rolled - never fold sharply

- Replace when silicone coating shows significant wear

- Follow the exporter's specific care instructions

Proper maintenance extends product life and ensures consistent protection. Many glassfiber welding blanket exporters provide replacement programs for worn blankets, helping you maintain safety standards cost-effectively.

Future Trends in Welding Protection

Leading glassfiber welding blanket exporters are developing:

- Lighter weight materials with equal protection

- Improved flexibility for complex shapes

- Smart blankets with temperature sensors

- Eco-friendly manufacturing processes

- Enhanced visibility colors for safety zones

When evaluating a glassfiber welding blanket exporter, inquire about their R&D investments. Progressive suppliers continuously improve their products to meet evolving industry needs and safety regulations.